SimSight

Physics | Insights | Decisions

SimSight for Scale-up/ Asset Selection / Rating

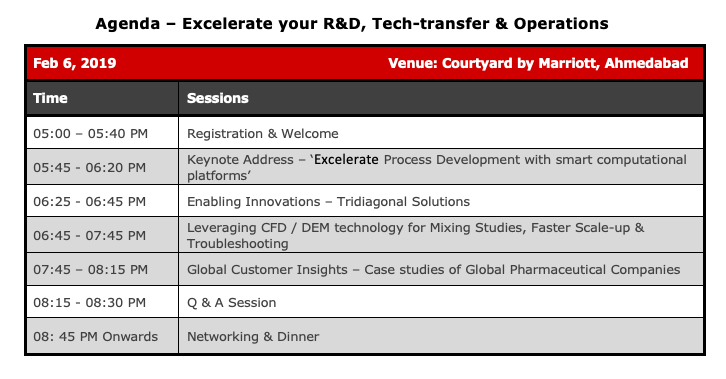

In today’s cost competitive / low margin industries, effective process development is essential for smoother technology transfer, reduced manufacturing issues, higher product quality, lower processing costs, and faster time to market. The industry, which relies more on ‘validation-by-experiments’ and past experience is always fraught with multifaceted challenges, when it comes to scaling-up and commercialization. Of course, scaling up smoothly, by a factor of up to 100 or 1,000, presents certain technical challenges. It’s essential that the golden-batch profile identified during discovery stage exhibit the same critical quality attributes (CQA’s), behaviors and characteristics as the product produced during commercial scales. In order to implement such ‘Quality-by Design’ framework, it is important to characterize the processes and performance metrics for each equipment, which enables process engineers to take some informed decisions.

Why SimSight?

The right equipment for ‘First-time-right’ approach needs process and asset characterization to identify and then optimize critical process parameters (CPP’s) for various unit operations. Today, process engineers spend more time in DOE studies and do OFAT/ univariate / multivariate analysis, which is cumbersome and time consuming (especially if non-standard equipment’s / multi-phase recipes are involved). How do Plant heads evaluate Asset utilization, Operating envelope, implement Process optimization /first-time-right manufacturing strategies and maintain/monitor CPP’s for consistent quality product (desired CQA’s)? Instead of relying on centralized teams, they need a solution, which can enable all these decisions at a plant level.

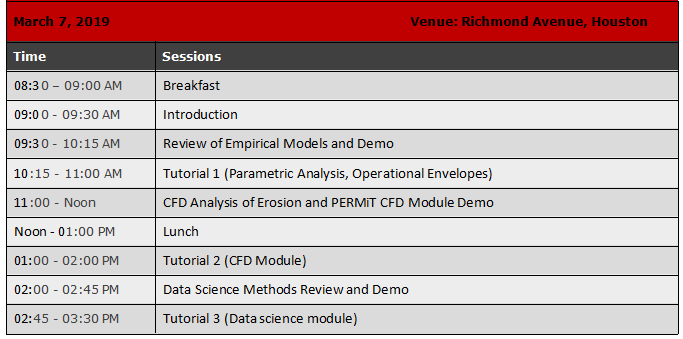

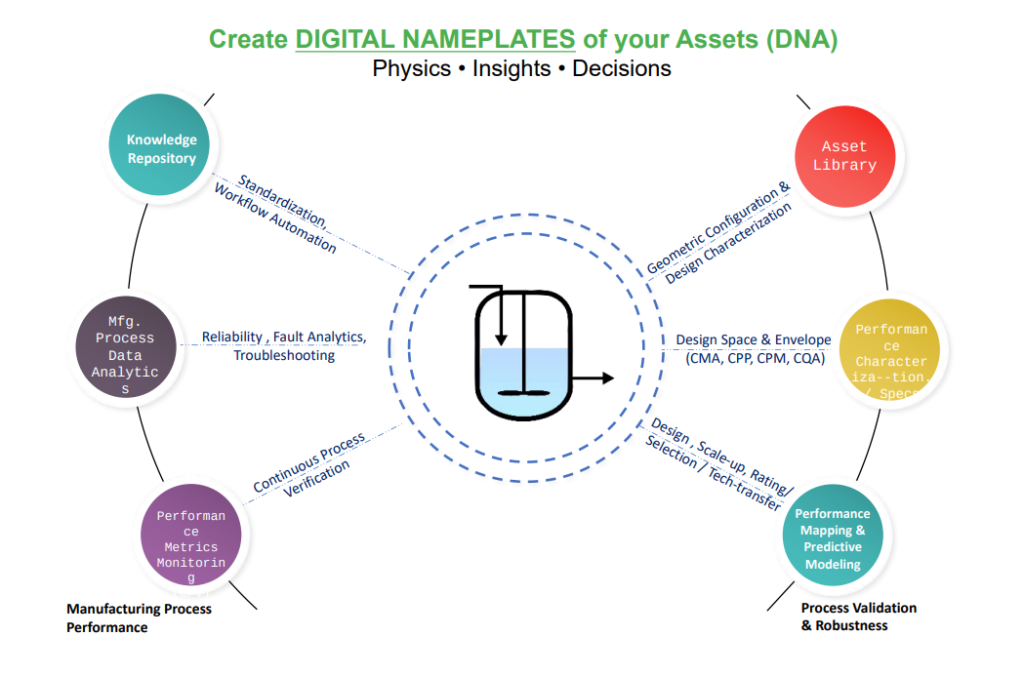

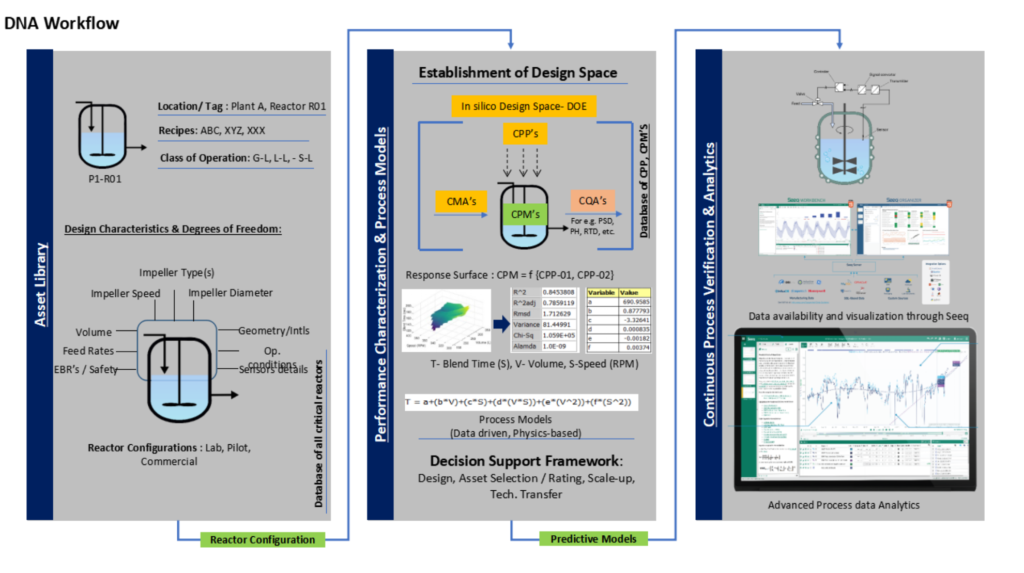

SimSight – SimSight is a science-based, data-driven framework that maps the fundamental performance characteristics of process assets/equipment

SimSight takes such ‘Asset-centric’ view to ‘Know how’ and ‘Know why’ for better process understanding through first principle /mechanistic modeling, building process models (mechanistic / data-driven) for predicting performance characteristics of each asset and creating a decision-support system for asset design / selection / rating and scale-up, technology transfer, etc.

This ‘Geometry aware’ framework enables process engineers to leverage the power of mechanistic and data-driven modeling to get performance (hybrid) models of Assets within the (defined)design space. The organizations can get such contextualized / characterized asset libraries for their plants, which has built-in experience/knowledge of process understanding and development.

SimSight enables digitalization initiatives as well by creating such digital assets, which when linked to live data, helps to do continuous process verification (CPV) using advanced data analytics platforms like Seeq.

Key Benefits

Reduced OPEX as a result of reduced production costs and overhead.

Increased capital efficiency, via improved asset utilization and capital reduction.

Reduced operational risks by reducing asset risks.

Recent Blogs

1. Manage scale-up and technology transfer risk with better process understanding-Part I

2. Manage scale-up and technology transfer risk with better process understanding-Part II

3. Manage scale-up and technology transfer risk with better process understanding-Part III

4. Manage scale-up and technology transfer risk with better process understanding-Part IV