Mixed Flow Pump

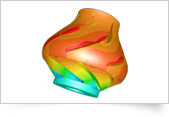

CFD analysis to improve the performance of Mixed Flow Pump.

The Experimental Division at Tridiagonal caters to the pilot and field scale testing needs of the Oil & Gas and the Chemical Process Industry segments.

Covering over 250,000 square feet, we operate one of the world’s largest multiphase flow laboratory servicing the Oil & Gas industry. However, Chemical Process Industry projects are focused on enabling Process & Product Innovations in Chemical, Consumer Product, Food and Pharma Industry. Experiments focus on foaming and aeration during bottle filling, drying & roasting, batch to continuous transformations, mixing and vortexing in stirred tanks, solids dissolution, coating etc. The key expertise of the team is design, construction and operation of lab and pilot scale plants based on sound multiphase flow and chemical engineering principles.

In Industrial process engineering, mixing is unit operation, which is one of the critical parameters. It involves the manipulation of the heterogeneous system into the homogeneous system. It is performed to allow heat and/or mass transfer to occur between one or more phases. Modern industrial processing almost always involves some form of mixing. With the right equipment, it is possible to mix a solid, liquid or gas into another solid, liquid or gas. Tridiagonal offers mixing testing facilities with below capabilities.

■ Measure fluid velocity using

■ Ultrasonic Velocity Profiler

■ Impeller Characterization Study

■ Measurement of Power Number

■ Measure Vortex shape and depth using high speed imaging

■ Perform mixing test using dye test

■ Characterize gas-liquid system

■ Gas hold-up measurement

■ Gas distribution profiles

■ Characterize solids-liquid system

■ Measure Njs

■ Solids concentration profile

These capabilities will help in getting data like Flow visualization, Non-intrusive and intrusive velocity measurements, Impeller power consumption, Mixing time analysis, Gas hold-up analysis and Gas volume fraction, which ultimately help the user to validate his study, makes the interpretation from available data, predict the batch quality, troubleshoot and scale up the product without much trial-n-error.

CFD analysis to improve the performance of Mixed Flow Pump.

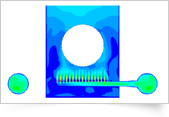

Using CFD to improve design of Quench Chamber for better quality.

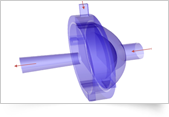

Evaluating performance of vortex amplifier using CFD model.

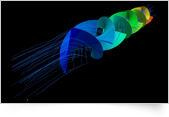

Study of flow pattern and mixing of power law fluid emulsion in Static mixers.

CFD analysis to study flow profile and effects of acid mixing in the tank.

Design of DSS to overcome challenges faced during complex formulation.

Developed by ThemeChampion

Pravin, one of the five members of Board of Directors in Tridiagonal Solutions has proven his expertise in creating, positioning and managing high growth companies. Mr. Jain has completed his Bachelors in Computer Engineering from University of Mumbai and Masters in Computer System Engineering from Northeastern University, Boston. He has also completed the Executive Program for Growing Companies at Stanford University Graduate School of Business. He has over 17 years of experience in Technology Entrepreneurship, Business Development and Delivery of Customer Centric Solutions. Pravin’s experience includes acquiring as well as divesting companies. Pravin lived and worked for 14 years in the US, and shifted back to India in the summer of 2006. He has driven, and been accountable for Sales, Marketing, Technology, Delivery and Strategy functions at his previous ventures. Pravin’s previous company grew by over 40x in 6 years and was subsequently divested to Wipro.

Dr. Damodaran Vedapuri heads the North American Operations of Tridiagonal Solutions. He obtained his doctorate from Ohio University. Dr. Vedapuri has wide experience in Computational Fluid Dynamics, Flow Accelerated Corrosion and solving Multiphase Flow Problems of interest to the oil and gas industry. Before joining Tridiagonal, he was employed with SwRI, a premier research lab in the US and at Fluent Inc.

Dr. Damodaran Vedapuri heads the North American Operations of Tridiagonal Solutions. He obtained his doctorate from Ohio University. Dr. Vedapuri has wide experience in Computational Fluid Dynamics, Flow Accelerated Corrosion and solving Multiphase Flow Problems of interest to the oil and gas industry. Before joining Tridiagonal, he was employed with SwRI, a premier research lab in the US and at Fluent Inc.