In complex process equipment, fluid-structure interaction can often lead to unexpected failures. Tridiagonal leveraged coupled CFD–FEA simulations to identify the root cause of repeated tube failures in an oxygen mixing device. The study revealed that fluid-induced vibrations from vortex shedding were exciting the natural frequency of sparger tubes, leading to structural resonance and eventual tube failure. While CFD accurately predicted the flow-induced vibration, FEA was used to estimate the mechanical natural frequencies of the tubes.

Based on the analysis, design modifications were recommended, including adopting oval-shaped tubes and adding additional mid-span supports to improve stiffness and offset resonance conditions. These insights enabled the client to significantly improve the reliability and longevity of the equipment. To discover more such real-world case studies where multiphysics simulations resolve complex industrial challenges, download the case study.

Related Use Cases

Use Cases

CFD Simulation of Shell & Tube Heat Exchanger

.png?length=400&name=Multiphase%20&%20Single-phase%20flow%20study%20for%20sand%20transport%20in%20inclined%20well%20(1).png)

Use Cases

Multiphase & Single-Phase Flow Study for Sand Transport in Inclined Well

Use Cases

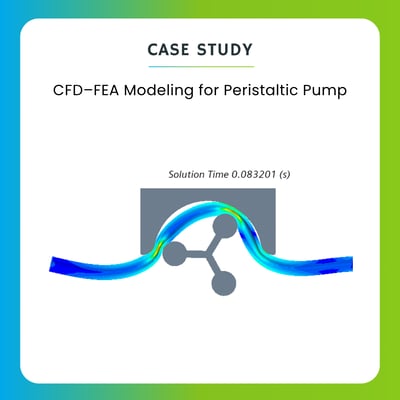

CFD-FEA Modeling for Peristaltic Pump

.gif?length=400&name=Shree%20Blog%20Templates%20TSPL%20(3).gif)

Use Cases

FEA to check Structural integrity of the Boiler Main Header and Stub Header

Have a Question?

If you need assistance beyond what is provided above, please contact us.