Process Consulting and Technology Solutions

Trusted Partner for process manufacturing optimization and digital transformation needs

Applying a breadth and depth of process expertise to address the range of business needs

We deliver ‘Value’ by leveraging advanced technologies to address process related challenges

Now Evolved as Tridiagonal.ai

At Tridiagonal.ai, we deliver next-gen AI and hybrid digital solutions for process industries.

Who We Are

Leveraging advanced technologies to support process industry needs

We are at the forefront of driving technological advancements, innovation, and transformation within process industry. We have been playing a catalyst role in leveraging advanced technologies to execute, implement and deploy solutions to address business problems of our customers.

Technology Catalyst - Innovate, Adapt and Transform

Tridiagonal solutions is at a forefront of driving technological advancements, innovation, and transformation within process industry. We have been playing the catalyst role in leveraging advanced technologies to execute, implement and deploy solutions to address business problems of our customers.

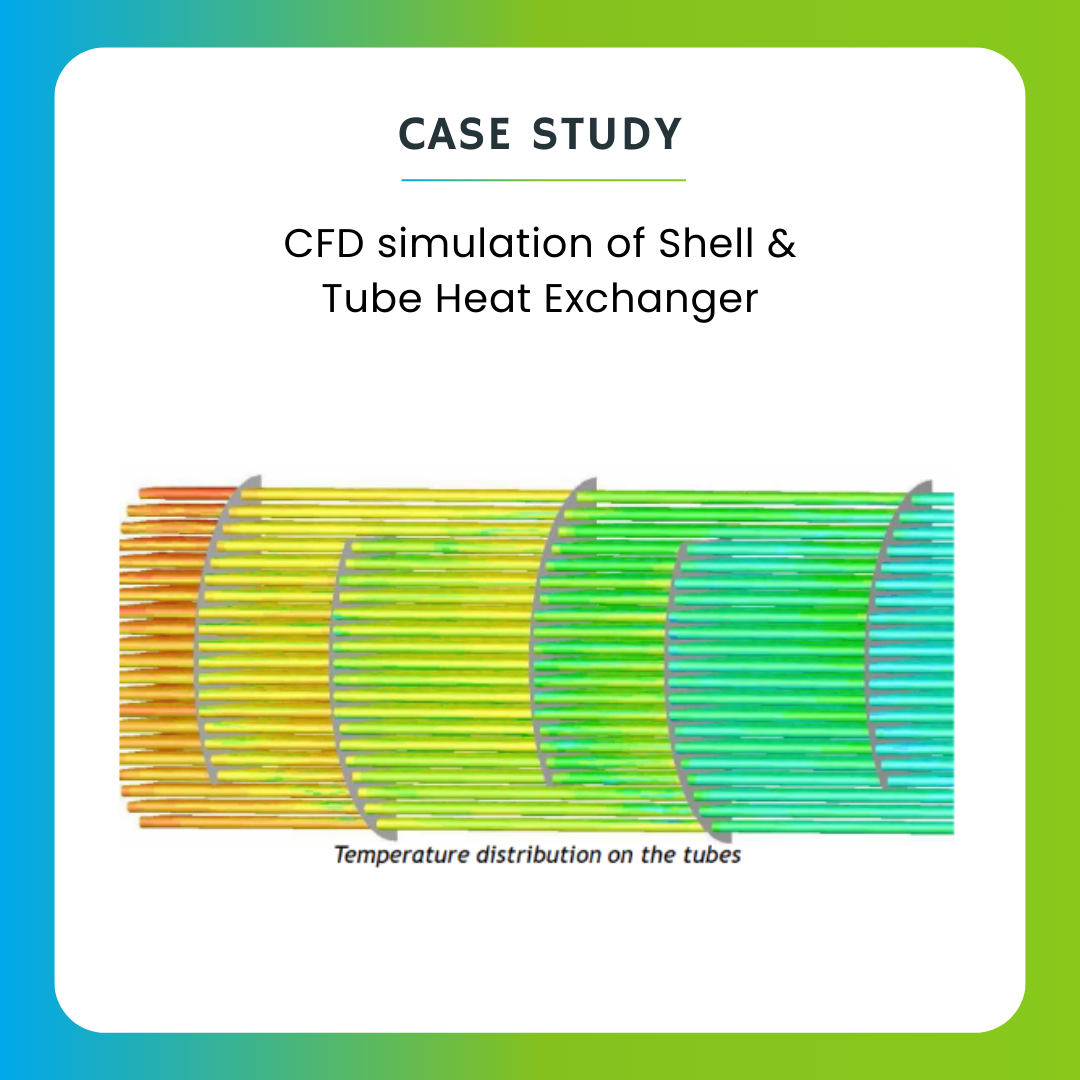

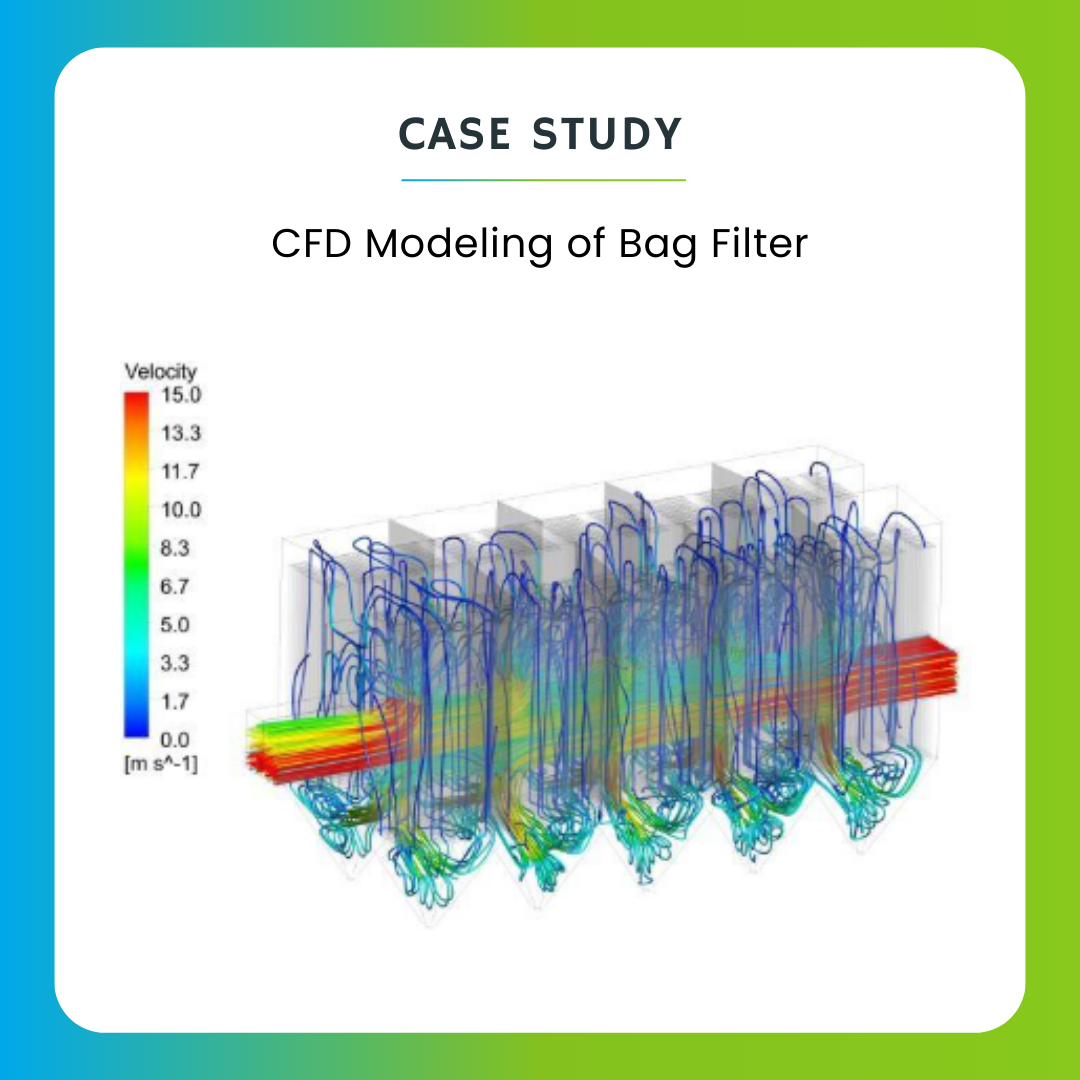

Core Expertise: Modeling & simulation (CFD, FEA DEM), Industry 4.0, IIOT, Process Data Analytics, AI-ML, Digital twin, Gen AI, Physical Testing – flow assurance, new technology testing (CCUS, Green hydrogen) TRL3- TRL9

We invest significantly in research and development to push the boundaries of what is possible in terms of technology and product development (for e.g. solver development, AI- ML models, automation using Gen AI, smart apps, templates/ libraries, etc.).>

Our combination of skillsets, process domain and technology exposure enable us to take the ownership of deployments thereby by assisting companies to adopt the technologies, which have a cascading effect on the strategies and operations of their businesses

We are leading the way in embracing emerging technologies such as Physics-based AI-ML, Digital twin, Gen AI, new technology validation and testing (Green Hydrogen, CCUS) and demonstrating how they can be practically applied.

We have been consistently introducing newer and disruptive technologies that reshape the process industry landscape by leveraging our industry partner ecosystem, research institutions, startups, etc.

For e.g. Industry 4.0, Process optimization, Modeling & Simulation, Physical testing and validation of new technologies

We have a culture of continuous learning, adaptation, and agility to stay ahead in a rapidly changing technological landscape. Our process excellence teams continuously innovate, develop and create value for our customers

With 16+ years of experience in delivering advanced solutions for multiple industries, we have developed implementation best practices. The combination of our skill sets, and technology understanding enables us to support our customers' operational excellence initiatives.

Operations Excellence – Implementing best practices

Tridiagonal Solution have deep domain and process expertise in various industries (continuous/ batch / discrete). Its combination of skillsets, breadth and depth of the process knowhow, exposure to multiple tools/ techniques/ solutions has enabled us to develop best practices for delivering solutions to the customers.

Core Expertise: Expertise: Production / Process Optimization, Energy Optimization, Quality Prediction, Safety and Sustainability, Equipment Modeling and Simulation, Physical testing and validation.

Our subject matter experts bring deep process expertise for various process industries. Right from the inception, we have been focusing on addressing core / specific process problems using technology. This has enabled our team to comprehend the knowledge, best practices and methodologies; thereby providing process excellence solutions

Our combination of skillsets (process domain + Industry experience + technology exposure) enables us to contextualize the problem in a scientific way and provide the practical solutions. Our 100+ man years of experience in multi-domain/ technologies have helped companies to successfully solve/deploy solutions

Over 16+ years, we have worked in multi- domain / technologies across different industries such as Oil & Gas, Pharma/life sciences, Metals & Mining, Cement, etc. This breadth and depth consist of different processes (upstream / downstream), classes of problems, technologies leveraged, etc.

For e.g. Industry 4.0 tech stacks, Process optimization, Modeling & Simulation, Operator training simulation (OTS), Physical testing and validation of new technologies

One of our core strengths while solving the problem is to provide right approach, methodologies and solution(s). The domain understanding, breadth and depth, and combination skillsets have helped us to create the best practices, templatize workflows and successful delivery and deployment of solutions

For e.g. IT-OT integration, Process optimization, Modeling & Simulation, Energy optimization, Physical testing and validation of new technologies

Our core focus is to identify, create and deploy value for the solutions we deliver. Our approach is to identify right problem and define the objectives that are solvable. The domain understanding and technology expertise help us to contextualize the problem / data and create right solutions. This eventually helps to accelerate the delivery of process excellence solutions thereby creating value for our customers

Value-driven Program: Time-to-value accelerator (TTV-A 33) Click here

Tridiagonal Solutions is committed to implementing sustainable practices in its operations and continuing to invest in developing new capabilities to support sustainability requirements in the process industry. We support Innovation enablement programs for CCUS, Green Hydrogen, and more.

Sustainability – Energy Optimization and Technology Validation / Commercialization

Tridiagonal Solutions is committed to implement sustainable practices in its operations as well as continue to invest in developing new capabilities to support process industry sustainability requirements. We support Innovation enablement programs for scope 1, 2 energy optimization, GHG, CCUS, Green Hydrogen, etc.

Core Expertise: Scope 1, Scope 2 Energy Optimization using modeling/simulation and digital technologies, GHG reporting, Circular economy, CCUS and Green Hydrogen technology testing (TRL3-TRL9).

ompanies can achieve margin improvement of 10-15% in EBITDA by focusing on three key levers of performance excellence – Profit, People and Planet. We leverage technology solutions to achieve efficient, safe and sustainable operations.

Business Objectives: Throughput/yield improvement, Energy efficiency, predictive analytics for safety, Scope 1 and Scope 2 energy management and Opex-based recommendations

Digital technologies / Industry 4.0 tech stacks enable companies to continuously monitor emissions and also predict the specific heat consumption and emissions across the plant operations. Digital twin of assets/ process units can be created to see the ideal vs actual emissions and also codify the recommended actions for carbon abatement. APC / AI-based process control can run operations optimally.

Technologies: CFD, Heat-integration studies, Digital Twin, Predictive analytics, Advance Process control, AI-based process control, Predictive emissions monitoring system (PEMS)

Tridiagonal has built an innovation and testing facility for technology validation programs. It includes the studies for Carbon Capture Utilization and Storage (CCUS), Green hydrogen, etc. We take the responsibility of Technology readiness level prototyping for TRL 3-10 (Research, Development, Demonstration)

Tridiagonal Solutions have been applying CFD-based modeling approaches for estimating and minimising the level of NOx / Sox production during the combustion in various equipments.

For e.g. CFD modeling & simulation of burner, Flue gas desulphurization, Furnace, Air pollution equipment, Boilers, Cement Kilns, HRSG

We have developed the collaboration ecosystem of R&D establishments, research institutes, in the production technologies. We are partnering with technology providers, and adapting it to Indian requirements. The scope of collaboration includes shortlisting TRL technologies, selection of module and stack size, making choice of technology, defining system configurations, Optimizing the efficiency, and cost reduction tradeoffs, etc.

Technology testing: CCUS, Green Hydrogen

What would you like to work on?

Advancing Technology from TRL3 to TRL 9, CCUS-Carbon Capture Utilization and Storage, Enhanced Oil Recovery (EOR), Sustainable Energy Transition, Carbon Offset Implementation, Green Hydrogen Technology Testing & Validation, Renewable Power Integration Battery Testing.

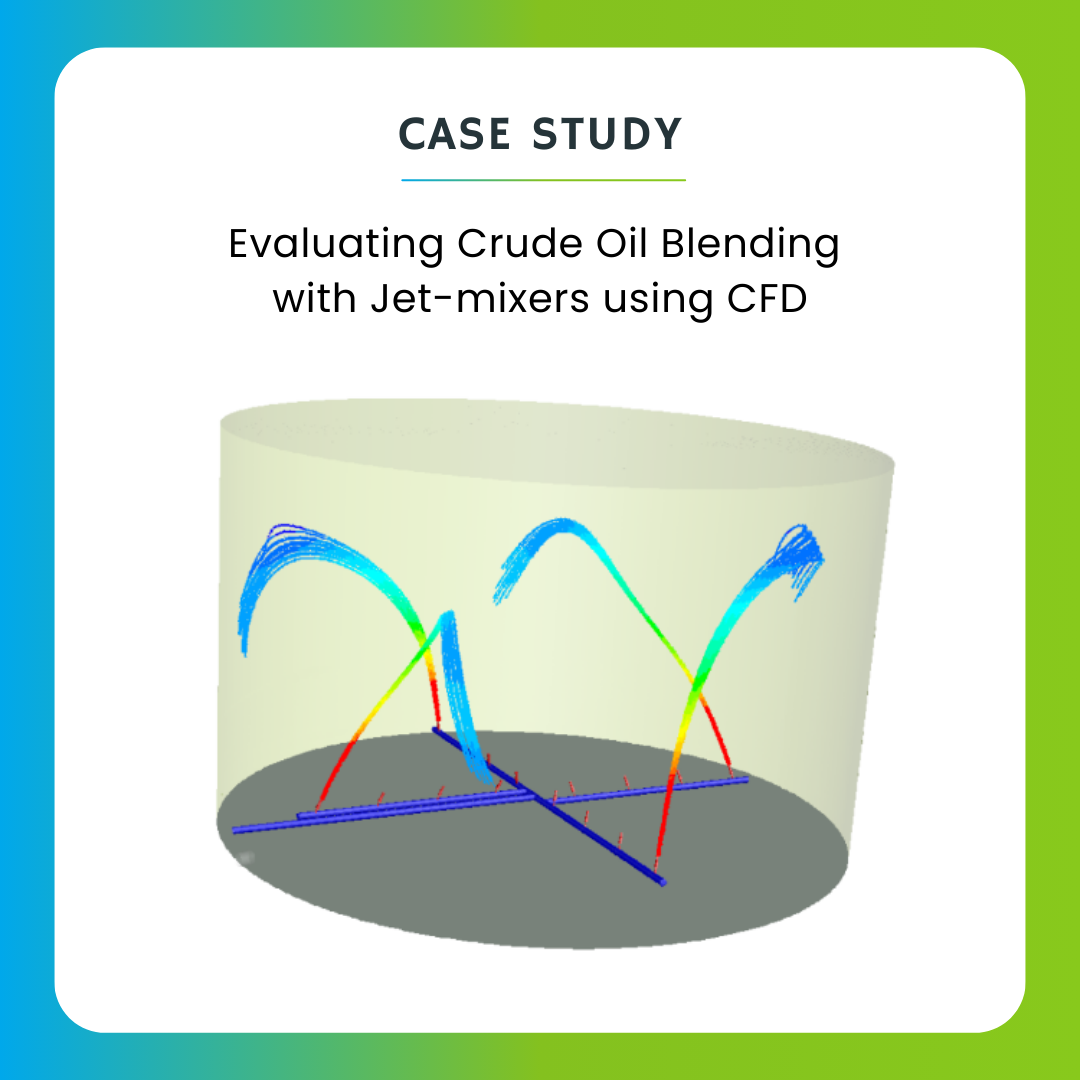

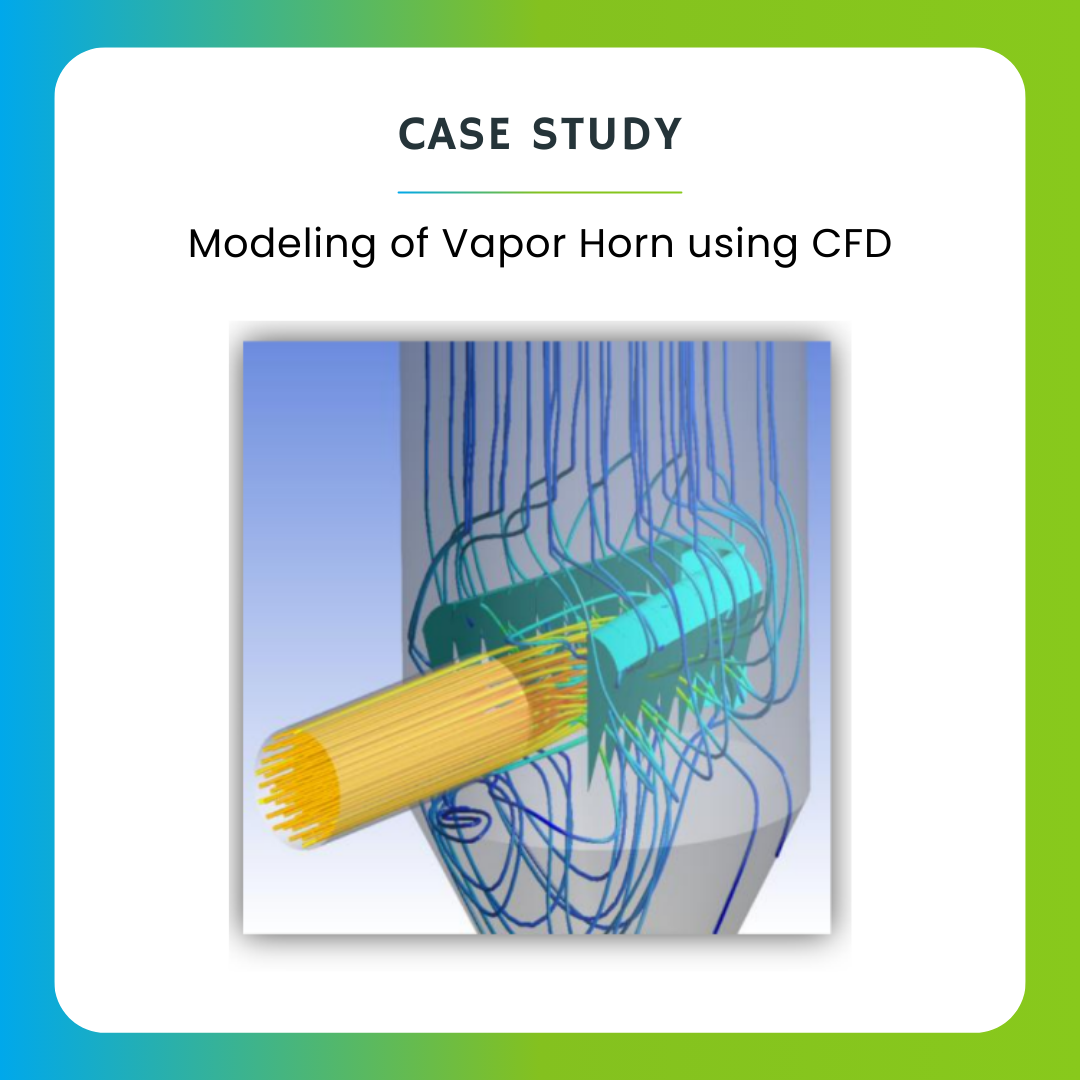

It includes Analyze two-phase flow of steam and water in boilers, simulate the flow of oil, water, and gas through a subsea pipeline and maximize the separation efficiency, whereas Combustion modeling includes flame impingement on radiant tube section leads to high tube metal temperatures which cause tube deformation, distortion, and rupture. And to study temperature distribution. We are using tools like ANSYS and Star CCM for simulation

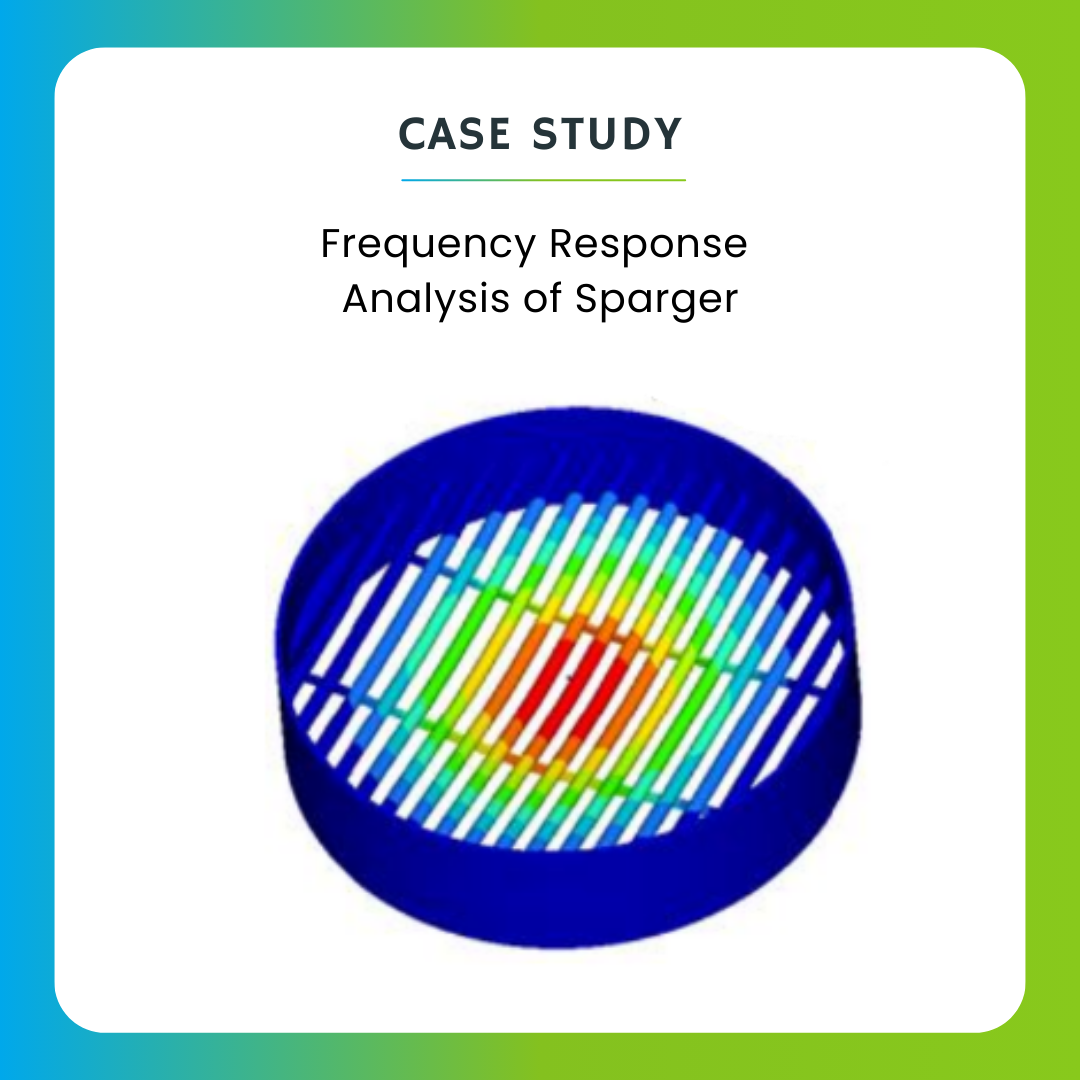

Simulating the complex interplay between fluids and structures using effective coupling of CFD and FEA. We do static structural analysis to check safety of separator under high pressure operating condition. We are using tools like ANSYS, Star CCM and LS Dyna for simulation.

Wax Mitigation, Asphaltene Management, Sand Management, Liquid Metal, Hydrate & CO2 Transport, Pipeline Flow Analysis, Flow Regime Identification, Inhibitor Screening, Slurry Rheology, and Erosion testing(Screen, Valve, elbows, joints, pipes, etc), Sand Blast, Sand Retention, and ICD Testing. Lab and field scale Corrosion testingTechnology Partners- All names should be displayed. Add a Know more link and redirect it to the Partner Solutions Page

Unveiling Our New Brand Identity

Welcome To Tridiagonal Solutions Fresh look! Check out our journey of delivering process excellence.

Use Cases

Resources

Explore the best practices and success stories of application of technology in process industry

CFD-DEM applied to Catalyst-Particles in Packed Bed Reactors or Columns | Webinar

Introduction: The shape, size and packing of catalyst particles plays significant role in the performance of packed bed ...

Read MoreFluid Structure Interaction Analysis (FSI): Maximizing Efficiency and Safety in Critical Industries

In the fast-paced industrial landscape, the challenges faced by sectors such as oil and gas, crude refining, power ...

Read MoreSand Transportation for Extending Life of ESP-Assisted Wells

Sand production remains one of the most persistent challenges in artificial lift operations, often leading to reduced ...

Read MoreExplore our Culture and People

Are you seeking an exciting role that will challenge and inspire you? Work with diverse and driven people on global projects that are truly shaping the process industry. Seize the opportunity to learn, grow, and realize your ambitions.

Welcome to The Education Online Learning

Explore Our Culture and People

Are you seeking an exciting role that will challenge and inspire you? Work with diverse and driven people on global projects that are truly shaping the process industry. Seize the opportunity to learn, grow, and realize your ambitions.

Looking for Trusted Partner for executing your programs?

We bring together unparalleled expertise with combination of skillsets and technology to address your digital, computational and testing needs

.png)