Technology Validation & Scale-up Centre

& Scale-up Centre

About Practice

Tridiagonal Solutions Pvt. Ltd., leveraging one of the Asia's largest experimentation lab and field-scale flow testing facilities to access indispensable production enhancement data. For over 15+ years, we've been catering to the needs of Fortune 500 companies, to bridge the gap between data and informed decision-making, providing validation and proof of concept for optimal field operations.

About Practice

Tridiagonal Solutions Pvt. Ltd., leveraging one of the Asia's largest experimentation lab and field-scale flow testing facilities to access indispensable production enhancement data. For over 15+ years, we've been catering to the needs of Fortune 500 companies, to bridge the gap between data and informed decision-making, providing validation and proof of concept for optimal field operations.

Capabilities

As a distinguished centre of excellence, with a strong process background, a combination of skill sets, and a sturdy partner eco-system, we have been quite capably supporting corporate R&D groups, Process Technologists, Plant Operations, and Maintenance teams with a multitude of services and solutions. We are specialized in a comprehensive range of multiphase flow testing and process optimization ranging from wax and asphaltene deposition, transportation of sand, liquid metal, hydrate & CO2. Our expertise extends to corrosion testing on both lab and pilot scale, Erosion testing for screens, elbows, valves, burst collapse, sand blast, sand retention, ICD testing and new technology scaling up solution form TRL3 to TRL10 for CCUS, H2, and EOR.

Comprehensive assessment for Component Wear Analysis (Screen, Valve, elbows, joints, pipes, etc), Erosion Resistance Evaluation, Surface Damage Assessment, Erosion Rate Measurement, Validation and Correction of Models, Mechanism Investigation, Protective Coating Performance Testing, Equipment Integrity Assurance, Sand Blast, Sand Retention, and ICD Testing.

Lab and field scale assessment to ensure material integrity at each stage of development.

Advancing Technology from TRL3 to TRL 10, CCUS-Carbon Capture Utilization and Storage, Enhanced Oil Recovery (EOR), Sustainable Energy Transition, Carbon Offset Implementation, Green Hydrogen Technology Testing & Validation, Renewable Power Integration Battery Testing.

Who We Are

Flow Assurance

With a focus on proactive testing and innovative solutions, Tridiagonal Solutions is a trusted partner for smooth flow of operation from reservoir to processing facilities, minimizing downtime and maximizing production efficiency for oil and gas. Our state-of-the-art facilities allow us to assess and mitigate issues such as wax deposition, asphaltene precipitation, transportation of sand, liquid metal, CO2 hydrate.

Flow Assurance

With a focus on proactive testing and innovative solutions, Tridiagonal Solutions is a trusted partner for smooth flow of operation from reservoir to processing facilities, minimizing downtime and maximizing production efficiency for oil and gas. Our state-of-the-art facilities allow us to assess and mitigate issues such as wax deposition, asphaltene precipitation, transportation of sand, liquid metal, CO2 hydrate.

Flow Assurance

With a focus on proactive testing and innovative solutions, Tridiagonal Solutions is a trusted partner for smooth flow of operation from reservoir to processing facilities, minimizing downtime and maximizing production efficiency for oil and gas. Our state-of-the-art facilities allow us to assess and mitigate issues such as wax deposition, asphaltene precipitation, transportation of sand, liquid metal, CO2 hydrate.

Industries

Your Trusted Partner in Technology Validation & Scale-up Centre

Oil & Gas

Tridiagonal pioneers advanced solutions for oil and gas industries, optimizing processes with cutting-edge flow assurance techniques, erosion-corrosion resilience, and precise multiphase flow analysis, ensuring robust operations and asset longevity.

Life Sciences/Pharma

At Tridiagonal, we revolutionize pharmaceutical manufacturing, mastering intricate mixing dynamics, anti-foaming agent efficacy, granulator efficiency assessment, and seamless scale-up strategies, ensuring precision and excellence in drug formulation.

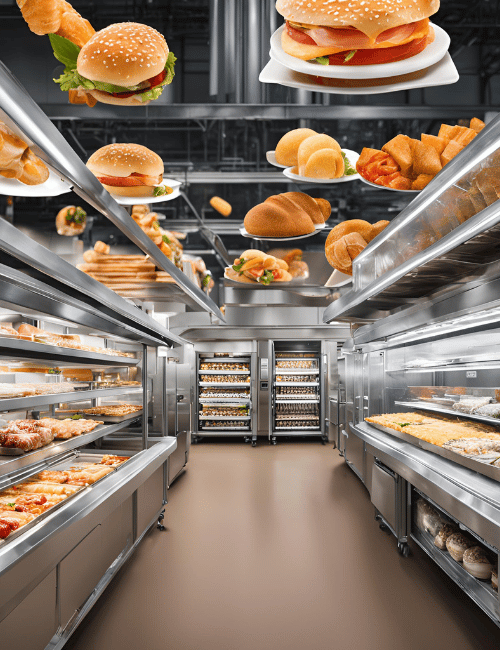

Food & Beverage (F&B)

Tridiagonal offers expertise in Mixing Solutions, Preservative and Emulsifier Testing, Additive Analysis, Heating and Cooling Efficiency Assessment, and Bottle Testing for enhanced F&B processing.

Chemicals & Petrochemicals

Tridiagonal pioneers' resilience in chemical processes, safeguarding against corrosion, optimizing mixing intricacies, scaling up productions seamlessly, engineering efficient reactors and distillation columns, and maximizing heat exchange efficiency, ensuring chemical excellence and reliability.

Power & Renewables

Tridiagonal pioneers in emerging areas such as Renewable Energy Integration, Carbon Capture Utilization and Storage (CCUS), Green Hydrogen, Sustainable Energy Transition, and driving innovation for a greener future.

Resources

Explore the best practices and success stories of application of technology in process industry

CFD-DEM applied to Catalyst-Particles in Packed Bed Reactors or Columns | Webinar

Introduction: The shape, size and packing of catalyst particles plays significant role in the performance of packed bed ...

Read MoreFluid Structure Interaction Analysis (FSI): Maximizing Efficiency and Safety in Critical Industries

In the fast-paced industrial landscape, the challenges faced by sectors such as oil and gas, crude refining, power ...

Read MoreSand Transportation for Extending Life of ESP-Assisted Wells

Sand production remains one of the most persistent challenges in artificial lift operations, often leading to reduced ...

Read MoreWhy Tridiagonal?

Tridiagonal Solutions, a top facility in Asia, offers cost-effective flow assurance testing for Oil & Gas majors. We are specialized in multiphase flow, erosion-corrosion, wax deposition, and sand management, etc. We collaborate with industry leaders, consultants, EPCs, OEMs and service providers, with flexible business models.

250k+ sq. ft. facility, Advanced equipment's, Lab & field scale testing, 24/7 utility

Leverage cheap labour and pre-built loops tailored to client needs.

Our EPC team creates custom skids quickly. Local network accelerates projects.

Deploying sustainable practices to efficiently create and deliver value for customers.

Practice Heads

Dr. Damo Vedapuri is the Head of North American Operations at Tridiagonal Solutions. He has 20+ years of experience in solving a wide range of fluid flow problems in the Oil and Gas industry. Some of his core focus areas are Erosion, Erosion – Corrosion, Sand Management, and Slurry Multiphase Flow. Dr. Damo has graduated from the Institute of Corrosion and Multiphase Technology at Ohio University with a Ph.D. degree in Chemical Engineering. He is a member of SPE and actively publishes his group’s research in SPE, OTC, NACE and BHR conferences.

.jpg?width=2000&height=2000&name=RTP_4433%20(2).jpg)

.png?width=501&height=498&name=Image__1_-removebg-preview%20(1).png)

With 44+ years experience, Dr. Lee is working as consultant and earned his Ph.D. in Organic Chemistry from the University of North Carolina. Dr. Lee has worked on flow problems with Chevron in upstream, midstream, refining, LNG, and chemical areas such as Heat Transfer, Sand Transport, Sand Management, Erosion, Multiphase Separation.

With 33+ years experience, Dr. Ravindra serves as a Consultant overseeing operations, maintenance, and construction of new facilities. Dr. Ravindra holds MS degree in Civil Engineering from Pune University and Ph.D. in the energy sector. His expertise lies in erecting large chemical plants, operational excellence, EPCM, modular engineering.

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.