In reverse-air baghouses, uneven gas flow can directly impact filtration efficiency, pressure drop, and bag life. This case study applies CFD to analyze internal flow behavior within a compartmentalized bag filter system under operating conditions.

The simulations focused on achieving uniform gas distribution across compartments, balancing inter-compartment flow, and minimizing pressure losses. Based on the findings, optimized guide vanes, baffles, and flow-control elements were recommended to enhance filtration performance and extend bag service life. Download the case study to explore CFD-based baghouse flow optimization strategies.

Related Use Cases

Use Cases

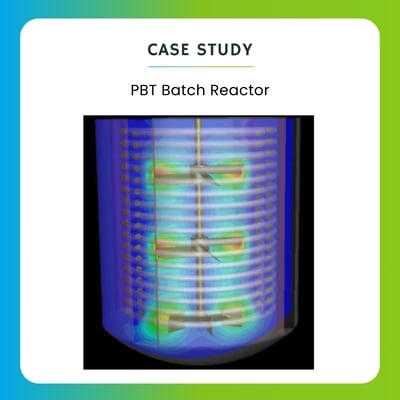

PBT Batch Reactor

Use Cases

Designing & Developing Air-Oil Filter for Mobile Rotary Compressor

Use Cases

Simulating Data Centers using CoolSim

.png?length=400&name=Electrostatic%20Precipitator%20(ESP).png)

Use Cases

CFD Modeling of Electrostatic Precipitator

Have a Question?

If you need assistance beyond what is provided above, please contact us.