Welding-induced residual stresses in pressure vessels pose significant risks—compromising structural integrity and leading to potential cracking under fluctuating pressure and thermal loads. This makes post-weld heat treatment (PWHT) a critical step in ensuring long-term durability. At Tridiagonal Solutions, our simulation experts developed a Finite Element Analysis (FEA) model that precisely captures the effects of heat treatment using a coupled transient thermal-structural approach. By focusing on critical weld junctions, we assess stress patterns in line with WRC Bulletin 452 and AWS D standards, helping to ensure design reliability and code compliance.

Whether you're a manufacturer, EPC contractor, or plant operator, this case study demonstrates how virtual testing can improve safety margins while minimizing downtime. Download the full case study to gain valuable insights into our engineering methodology and results.

Related Use Cases

Use Cases

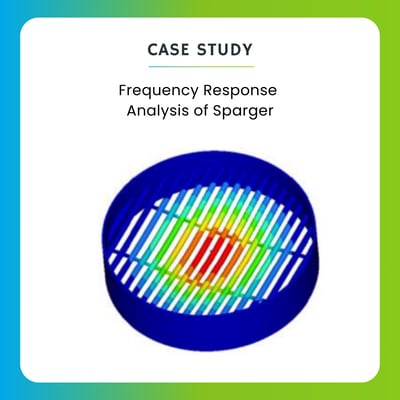

Frequency Response Analysis of Sparger

Use Cases

Impact of Projectile on Storage Tank

Use Cases

Sand Control Screen Erosion and Flow Performance

Brochure

Asphaltene Deposition Facility

Have a Question?

If you need assistance beyond what is provided above, please contact us.