Efficient operation of a three-phase separator tank depends largely on how well the phases are separated under gravity. One of the most critical design factors influencing this process is the position and configuration of baffles, which directly affect flow distribution and separation efficiency.

In this study, CFD simulations were performed to evaluate the effect of baffle placement and particle diameter on separation performance. The results provided clarity on which design parameters deliver more effective phase separation, enabling improved reliability and efficiency of the separator. See how design insights helped optimize the separation process in this case study.

.png?width=470&height=321&name=Three-Phase%20Separator%20Tank%20(1).png)

Related Use Cases

Use Cases

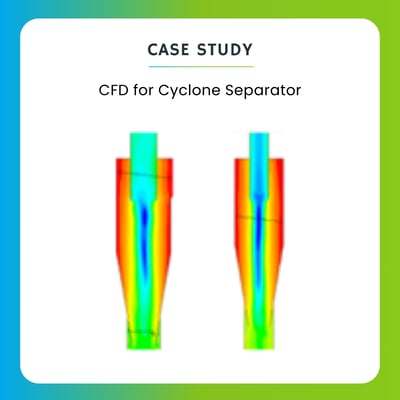

CFD for Cyclone Separator

Use Cases

Modeling of Vapor Horn using CFD

Use Cases

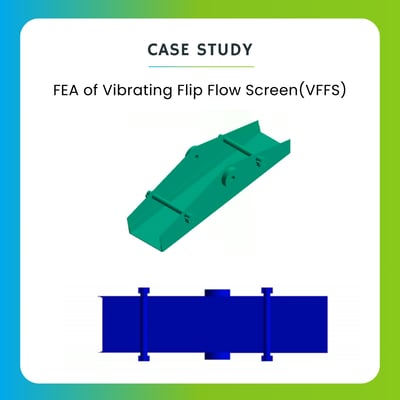

FEA of Vibrating Flip Flow Screen (VFFS)

Use Cases

Designing & Developing Air-Oil Filter for Mobile Rotary Compressor

Have a Question?

If you need assistance beyond what is provided above, please contact us.