Industrial fluid systems, particularly those operating under high-velocity and abrasive conditions, place immense stress on essential components such as elbows, tees, reducers, and 3D pipe templates. Over time, this can result in significant erosion, jeopardizing equipment integrity, shortening component lifespan, and increasing operational risk. Tridiagonal Solutions offers a state-of-the-art Erosion Testing Facility designed to simulate realistic process conditions and evaluate the erosion performance of various stainless-steel grades, alloys, and component geometries. With this data, operators and manufacturers can proactively address weak points in design and material selection before costly failures occur.

Accelerate Innovation and Reliability through Large-Scale Testing

Our large-scale erosion testing setup enables detailed analysis of component behavior under aggressive flow conditions. Beyond standard material evaluation, the facility supports design optimization, validation of protective coatings, and assessment of erosion detection technologies. By coupling experimental results with modeling insights, we also offer empirical corrections to improve simulation accuracy and support predictive maintenance strategies. Download the brochure now to explore how Tridiagonal’s testing capabilities can help you extend equipment life, reduce unplanned shutdowns, and design more erosion-resistant systems for high-demand industrial environments.

Related Use Cases

Use Cases

Directional Solidification

.png?length=400&name=corrosion%20testing%20(1).png)

Brochure

Lab Scale Corrosion Testing

Blogs

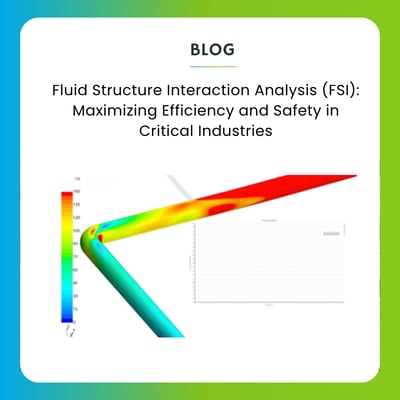

Fluid Structure Interaction Analysis (FSI): Maximizing Efficiency and Safety in...

Use Cases

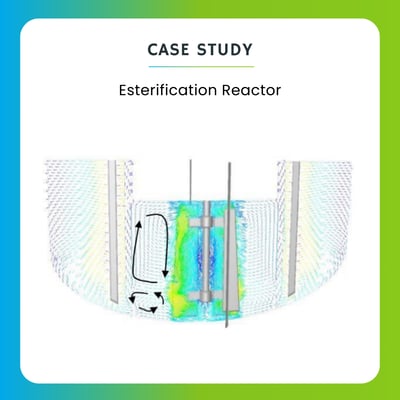

Esterification Reactor

Have a Question?

If you need assistance beyond what is provided above, please contact us.