Designing a Directional Solidification System (DSS) involves addressing the complex interaction between fluid dynamics, heat transfer, and crystal growth. In this study, advanced simulations were applied to evaluate critical phenomena influencing system performance, including phase change, unsteady multi-component flows, heat transfer with radiation, natural convection, and mild turbulence over the melt surface.

By capturing these complexities, the analysis provided deeper insights into the DSS process, helping overcome design challenges and enabling better prediction of crystal growth behavior. Explore the full case study to see how simulation simplified the complexities of DSS design.

Related Use Cases

Brochure

Erosion of Elbow and other pipe component Testing Facility

.png?length=400&name=corrosion%20testing%20(1).png)

Brochure

Lab Scale Corrosion Testing

Use Cases

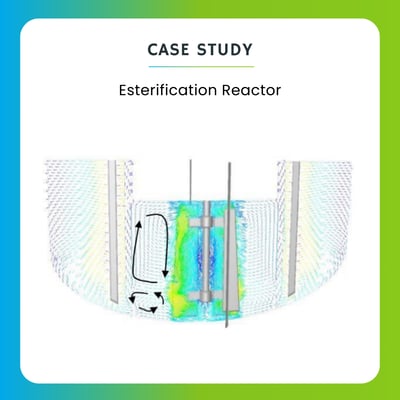

Esterification Reactor

Use Cases

Coffee Bean Dryer

Have a Question?

If you need assistance beyond what is provided above, please contact us.