Stay Ahead of Change

Brochure

Brochure

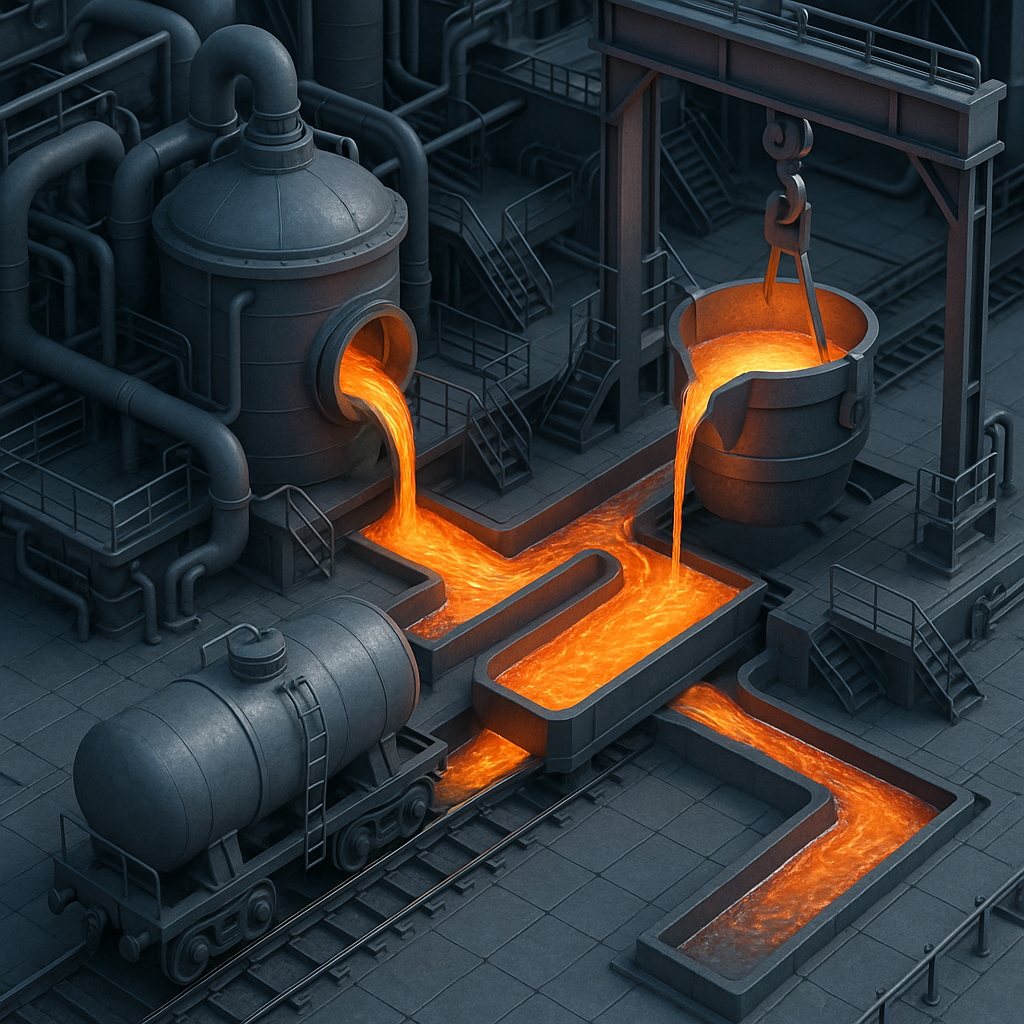

Liquid Metal Transportation Facility

Heavy metals like mercury often migrate from natural sources—such as source rocks, metal-rich fluids, and oil-producing organisms—and accumulate within oil and gas pipelines, especially in complex terrains. This build-up poses serious challenges including corrosion, flow assurance risks, and environmental hazards. Our Liquid Metal Transportation Facility enables a deep dive into these issues through controlled, pilot-scale multiphase flow experiments that simulate real-world pipeline conditions. These tests focus on entraining and transporting heavy liquid metals like mercury within the gas phase to support pipeline cleaning and operational safety.

Brochure

Brochure

Sand Retention Testing

Effective sand control is critical for ensuring long-term well performance and minimizing damage to production equipment. Tridiagonal Solutions offers high-fidelity sand retention testing (SRT) to evaluate and select the most suitable sand screens tailored to your specific reservoir conditions. Our advanced SRT setup replicates formation-specific particle size distributions (PSDs), enabling accurate evaluation of screen efficiency in retaining sand at the formation face while allowing uninterrupted oil and gas flow. This ensures reduced risk of solids production, well failure, and costly remediation.

Brochure

Brochure

Sand Transportation Facility

Sand production from weak reservoirs is a persistent challenge in the oil and gas industry. When sand becomes entrained in crude oil, it often settles at the bottom of the pipeline, forming stationary beds that lead to serious operational issues—ranging from reduced production rates and excessive pressure drops to equipment failure, erosion, and corrosion. Our Sand Transportation Facility is purpose-built to help operators and researchers address these risks. Through rigorous testing, we analyze the movement of sand in multiphase flow systems and determine the minimum sand transportation velocity required to ensure continuous flow in horizontal and inclined pipelines.

Brochure

Brochure

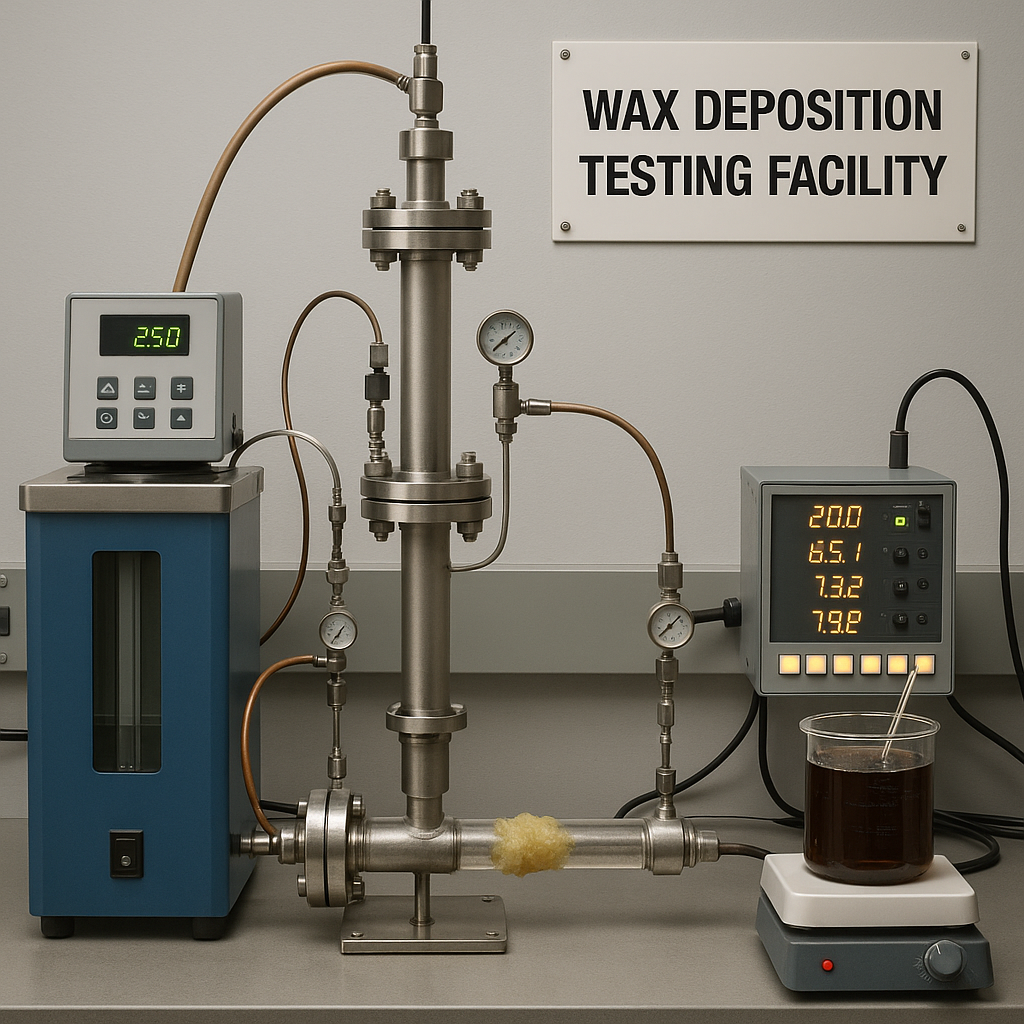

Wax Deposition Testing Facility

TSPL's wax deposition flow loop is a hub of innovation, driving transformative research in multiphase flow dynamics. With advanced instrumentation and visualization capabilities, it provides crucial insights into wax removal mechanisms. Pioneering initiatives conducted within the loop, like self-pigging technology and wax inhibition proofs, lead to substantial cost savings and enhanced operational efficiency for clients. This loop stands as a testament to TSPL's commitment to excellence and industry leadership.

Blogs

Blogs

Sand Blast for Erosion Testing in Coated Coupons: Strengthening Material Durability

Brochure

Brochure

Erosion of Elbow and other pipe component Testing Facility

Industrial fluid systems, particularly those operating under high-velocity and abrasive conditions, place immense stress on essential components such as elbows, tees, reducers, and 3D pipe templates. Over time, this can result in significant erosion, jeopardizing equipment integrity, shortening component lifespan, and increasing operational risk. Tridiagonal Solutions offers a state-of-the-art Erosion Testing Facility designed to simulate realistic process conditions and evaluate the erosion performance of various stainless-steel grades, alloys, and component geometries. With this data, operators and manufacturers can proactively address weak points in design and material selection before costly failures occur.

.png) Brochure

Brochure

Lab Scale Corrosion Testing

Corrosion, the gradual degradation of materials or metals due to chemical reactions with their environment, poses significant challenges in industries ranging from infrastructure and manufacturing to transportation and energy. To ensure the longevity and reliability of materials, it is essential to employ rigorous corrosion testing methods.

Brochure

Brochure

Control Valve Erosion Testing

Case Studies

Case Studies

Liquid Entrainment and Jumper Study Flow Facility for Hydrate

This multipurpose test facility is utilized to conduct a number of multiphase flow studies ranging from hydrate transport to liquid entrainment. Hydrate mimic studies focus on understanding the impact of hydrate particles on flow regimes transitions and multiphase flow characteristics. Poly propylene particles are used as hydrate mimics. These particles float at the interface of oil and water. Liquid entrainment studies focus on determining the entrainment flux in low liquid loading systems. Starting from onset of entrainment when the first set of droplets are observed in the gas phase to close to a 97% entrainment, these studies focus on how gas velocities impact entrainment flux in both air-water and air-oil systems.

Brochure

Brochure

Asphaltene Deposition Facility

Asphaltene deposition remains one of the most persistent flow assurance issues in oil and gas production. These complex, heavy organic molecules can quickly accumulate, clogging flowlines, damaging equipment, and significantly reducing production efficiency. The challenge? No single mitigation strategy works across all reservoirs or crude types. Asphaltene behavior is highly dependent on the oil's composition, reservoir pressure and temperature, and even the effectiveness of chemical inhibitors varies widely. At Tridiagonal Solutions, we recognize the need for tailored solutions—not generalized fixes.

Case Studies

Case Studies

Mixing Studies

Embark on a journey into the heart of our technological expertise, Mixing Facility. In the realm of the Chemical sector, optimizing tank configurations for increased yields is paramount. Challenges arise in determining the optimum configuration of mixing tanks, selecting the appropriate impeller type, impeller position, and impeller clearance to enhance yields through the mixing process without generating unwanted vortex.

Case Studies

Case Studies

Development of Gas Void Fraction Sensor System

Understanding in situ gas volume fraction is critical for optimizing gas-liquid systems, especially in complex flow regimes. While overall gas holdup measurement is relatively simple, accurately capturing local gas holdup remains a significant challenge due to system opacity and noise interference.

.webp) Case Studies

Case Studies

Foam Transportation Loop

In the realm of multiphase flow dynamics, understanding the intricate behavior of foams is essential for numerous industrial applications, particularly in the oil and gas sector. Tridiagonal's Foam Transport Facility stands at the forefront of this research, providing a state-of-the-art platform designed to delve into the complexities of foam generation and breaking mechanisms. This facility features a substantial 16-inch diameter, -foot-long flow loop, incorporating advanced mesh-type assemblies and comprehensive visualization sections. By generating foams using various surfactants and studying their behavior under diverse flow conditions, the facility offers unparalleled insights into foam dynamics.

Case Studies

Case Studies

Aeration and Foaming during Bottle Filling

Aeration and foaming during the bottle filling process can lead to significant product losses, underfilling, and operational inefficiencies. This case study presents experimental investigations conducted to understand the fundamental mechanics of aeration and foaming under various liquid properties and operating conditions.

Case Studies

Case Studies

Coffee Bean Dryer

Project aimed to create an efficient drying process that would not burn the coffee beans. To achieve this, Tridiagonal created a computational fluid dynamics (CFD) model and conducted a pilot plant proof of concept at TRL-3.

Case Studies

Case Studies

Paraffin Wax Stripping in Field-Scale Pipelines

Paraffin wax deposition in pipelines is a persistent challenge in crude oil transport, affecting flow efficiency and increasing maintenance costs. This case study explores the effectiveness of paraffin wax stripping under various operational conditions using a full-scale experimental pipeline setup.

Sand Control Screen Erosion and Flow Performance

Effective sand management is critical to ensuring the longevity and performance of oil and gas wells. Uncontrolled sand production can cause severe erosion in downhole equipment, leading to increased OPEX/CAPEX and reduced well productivity. This case study focuses on evaluating the erosion resistance and flow performance of sand control screens—key to retaining formation particles while enabling efficient fluid flow into production wells. Leveraging Tridiagonal’s advanced test loop setup, which includes a 2200 cfm gas compressor system (up to 7 bar pressure), and an in-house sand screw feeder (50–2000 g/hr dosing), comprehensive tests were conducted under realistic conditions. Additional capabilities like laser particle size distribution (PSD) analysis and Maximum Pore Passage (MPP) testing per API 19SS guidelines enabled precise performance evaluation. Download the full case study to explore how real-world testing and data-driven insights support the development of more robust, efficient sand control solutions for enhanced well performance.

.png) Case Studies

Case Studies

Multiphase & Single-Phase Flow Study for Sand Transport in Inclined Well

Understanding sand transport behavior in oil and gas wells is essential for designing effective sand management strategies. This case study presents a pilot-scale experimental loop designed to replicate wellbore conditions using tubular test sections with the same diameter as actual well designs, albeit at shorter lengths. The setup allows for both single-phase and multiphase flow studies to evaluate sand transport in inclined wells under realistic operating conditions.

-1.png) Case Studies

Case Studies

Liquid metal Transport

Mercury contamination in oil and gas pipelines poses serious challenges—leading to pipeline corrosion and environmental hazards due to biomagnification in marine ecosystems. This case study investigates the gas-assisted transport of liquid heavy metals, like mercury, to enable effective removal from pipelines.

.png) Case Studies

Case Studies

Erosion-Corrosion Testing

Erosion-corrosion experiments are pivotal for understanding the degradation processes in larger pipelines like 4-inch diameters, offering insights into the combined effects of both erosion and corrosion under real-world conditions. These insights are crucial for predicting and mitigating pipeline failures, guiding the development of robust materials and coatings, and optimizing maintenance strategies to ensure the safety, integrity, and longevity of larger pipelines.

Case Studies

Case Studies

Erosion Testing Setup

Tridiagonal Organization specializes in providing innovative solutions for various industries, including Oil & Gas, Pet Chemicals, Pharma, Food, Metals & Mining, Cement, etc. In these industries, equipment such as SS elbows, tees, reducers, and 3D templates are subjected to harsh operating conditions, including high velocities of abrasive fluids, which can lead to erosion. Erosion is a critical issue that can compromise the integrity and longevity of industrial components, resulting in costly repairs, downtime, and safety hazards. To address these challenges, Tridiagonal Organization has established a comprehensive erosion testing setup to assess the erosion resistance of its products and optimize their design and material selection.

Case Studies

Case Studies

Automated Inflow Control Device Erosion Testing Facility

Inflow Control Devices (ICDs) and Automated Inflow Control Devices (AICDs) are critical in enhancing well performance, balancing reservoir inflow, and minimizing unwanted fluid production. Tridiagonal Solutions offers a fully equipped testing facility designed to rigorously evaluate these devices under realistic wellbore conditions. Our testing portfolio includes cavitation testing, flow performance analysis, erosion resistance, and mud flow initiation and sediment plugging assessments—all in alignment with API 19ICD specifications. By simulating both single-phase and multiphase flows at pressures up to 200 bar, we deliver actionable insights to optimize device design and reliability in field deployment.