This case study focuses on the simulation and evaluation of impeller designs in a polymerization reactor to improve overall performance. The existing impeller was modeled, and several alternative designs were developed and analyzed to understand their impact on mixing dynamics. Detailed plots of strain rate distribution and Particle Size Distribution (PSD) were generated to compare performance across configurations.

Through this systematic study, the impeller configuration delivering superior PSD and improved flow characteristics was identified, offering clear design direction for reactor optimization. These insights highlight how CFD enables data-driven decision-making in critical reactor design challenges. Access the full case study to see how optimized impeller design enhanced process efficiency.

Related Use Cases

-1.png?length=400&name=unnamed%20(4)-1.png)

Use Cases

Liquid metal Transport

Use Cases

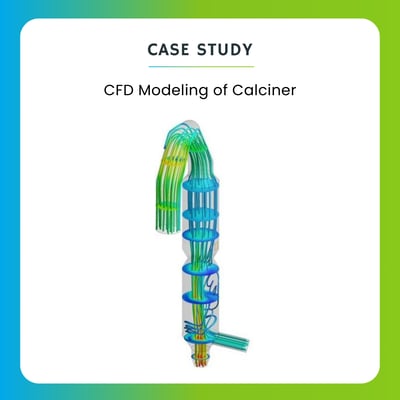

CFD Modeling of Calciner

.webp?length=400&name=Storage%20Tank%20(1).webp)

Use Cases

Liquid Flashing and Vibration in Storage Tank Feed Pipes

Use Cases

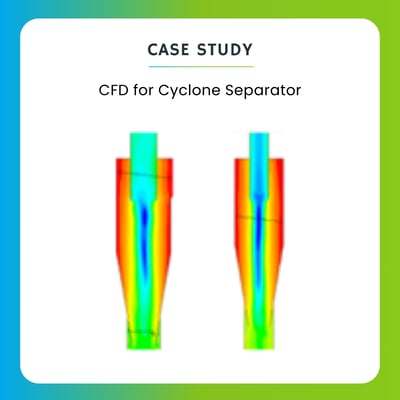

CFD for Cyclone Separator

Have a Question?

If you need assistance beyond what is provided above, please contact us.