Efficient calcination is essential for stable kiln operation and product quality. The calciner, positioned in the riser duct between the kiln inlet and bottom stage cyclone, plays a critical role in distributing raw materials evenly to prevent accumulation and enhance residence time. Using CFD simulations, the combustion process was studied under conditions of kiln exhaust gas mixed with tertiary air.

The objective was to evaluate calcination efficiency and predict exit gas composition with a reduced tertiary air inlet. The analysis provided valuable insights into airflow, combustion, and raw material distribution, enabling design and operating improvements. Learn how CFD supported optimization of calciner performance in this case study.

Related Use Cases

Blogs

Boosting Cement Industry Efficiency with Advanced CAE Simulations

Use Cases

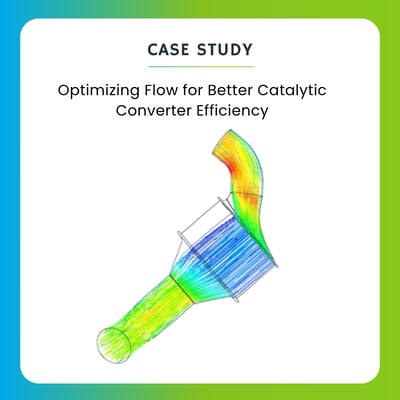

Flow Distribution in Catalytic Converter

Use Cases

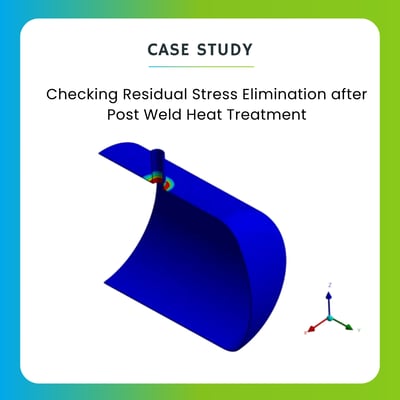

Checking Residual Stress Elimination after Post Weld Heat Treatment

.webp?length=400&name=Gas%20Plant%20(1).webp)

Use Cases

Assessment of FCC stripper vessel as per ASME SecVIII Div-2 code

Have a Question?

If you need assistance beyond what is provided above, please contact us.