This case study focuses on optimizing burner arrangements in a process heater using advanced simulations. By studying the behavior of velocity, pressure, and flue gas flow patterns, the analysis provided a clear understanding of how burner configuration influences heater performance and efficiency.

The insights gained helped in identifying improved designs that enhance heat transfer, reduce energy losses, and ensure stable operation of the process heater. Learn how simulation-driven optimization improved process heater performance in this case study.

Related Use Cases

Use Cases

Automated Inflow Control Device Erosion Testing Facility

.png?length=400&name=Erosion%20Testing%20Setup%20(1).png)

Use Cases

Erosion-Corrosion Testing

Brochure

Liquid Metal Transportation Facility

Blogs

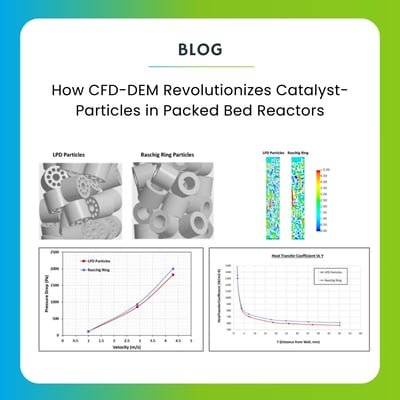

How CFD-DEM Revolutionizes Catalyst-Particles in Packed Bed Reactors

Have a Question?

If you need assistance beyond what is provided above, please contact us.