- Understanding CFD-DEM: An Overview

- The Importance of Catalyst-Particles in Chemical Reactions

- How CFD-DEM Enhances Reactor Design and Performance

- Key Benefits of Using CFD-DEM in Packed Bed Reactors

- Challenges and Limitations of CFD-DEM in Catalyst-Particles

- Future Trends in CFD-DEM and Packed Bed Reactor Technology

- Best Practices for Implementing CFD-DEM in Your Processes

- Conclusion: The Future of Efficiency in Chemical Engineering

- Case Studies: Successful Applications of CFD-DEM

In the world of chemical engineering or industries, efficiency is paramount, especially when it comes to effective use of catalyst particles in the packed bed reactors. As industries strive for greener processes and increased output, understanding the synergy between catalyst particles and fluid flow becomes essential. Enter the transformative power of CFD-DEM, a groundbreaking approach that is reshaping how we analyse and optimize these complex systems. By leveraging advanced simulations, CFD-DEM allows engineers to replicate the real packed bed and visualize flow dynamics around the catalyst particles in unprecedented details, leading to enhanced performance and productivity.

This article delves into the innovative ways that CFD-DEM is revolutionizing the shapes of catalyst particles that are not only more efficient but also poised to meet the demands of tomorrow’s sustainable practices. Join us as we unlock the full potential of this cutting-edge technology and explore its implications for the future of chemical processes.

Understanding CFD-DEM: An Overview

Computational Fluid Dynamics (CFD) and Discrete Element Method (DEM) are two powerful numerical techniques that, when combined, provide an unparalleled tool for analysing and optimizing particle-fluid interactions in various engineering applications. CFD focuses on the behaviour of fluid flow, allowing engineers to simulate and visualize complex fluid dynamics around particles within a system. While DEM, on the other hand, models the actual shape & size of discrete particles (here catalyst particles), accounting for their interactions, collisions and particle packing.

Packed bed reactors are widely used in chemical engineering for processes such as reforming, catalytic cracking, hydrogenation and gas absorption. In these reactors, when tube to particle diameter ratio is lower (<10), the heterogenous nature of packed bed has an impact on the fluid flow and the efficiency of reactions. The size & shape of catalyst particles has significant impact on the economics and efficiency of operation of packed bed reactors. Any real experiments? Well capturing the details of heterogenous packed bed and measuring its performance is experimentally challenging.

The integration of CFD and DEM can be particularly transformative in the context of resolving the bed of catalyst particles with actual shape & size in the simulations. In today’s world these are digital-twin or digital replica of real setup and enable the fundamental study of fluid flow, heat transfer and reactions within the reactor. CFD-DEM simulations allow engineers to capture the complexities of these interactions with high fidelity. By simulating the fluid flow and particle dynamics simultaneously, engineers can gain insights into how the catalyst particle properties (shape or size, surface active/inactive sites), the reactor design, the operating conditions can impact the overall performance of the reactor. Such level of details is crucial for selecting the shape, optimizing the reactor design and the process operation. These simulations are crucial enablers for business and operation decisions.

The Importance of Catalyst-Particles in Chemical Reactions

Catalyst particles play a pivotal role in chemical reactions, acting as facilitators that speed up the reaction rate without being consumed in the process. In packed bed reactors, these particles are strategically placed to maximize contact with the reactant fluid, thereby enhancing the efficiency of the reaction. Poorly distributed or improperly sized catalyst particles can lead to issues such as flow-channellings, regions of stagnation and ultimately resulting in uneven reaction rates, undesired reactions and reduced efficiency.

How CFD-DEM Enhances Reactor Design and Performance

CFD-DEM simulations can be used to evaluate different shapes, sizes of catalyst particles, reactor designs and configurations, allowing engineers to test various scenarios and identify the most efficient design. For example, simulations can help determine the optimal particle shape & size, as well as the best operating conditions for maximizing reaction rates.

The packed bed structure from DEM and temperature profiles from CFD can be used in the Finite Element Analysis (FEA) simulations to study the structural and thermal stability of catalyst materials. This can lead to the development of more efficient, minimized energy and cost-effective reactors. Result can be more sustainable and energy-efficient processes, aligning with the growing demand for greener chemical engineering practices.

In addition to optimizing reactor design, CFD-DEM simulations can also be used to troubleshoot and solve issues that may arise during reactor operation.

Key Benefits of Using CFD-DEM in Packed Bed Reactors

The use of CFD-DEM simulations in packed bed reactors offers several key benefits

-

One of the primary advantages is the ability to visualize and understand the complex interactions between catalyst particles and fluid flow. The greater level of details is crucial for fundamental understanding into design and operations. Such details are difficult to get from the experimental testing.

-

Another key benefit is the ability to test and evaluate different reactor designs and configurations without the need for extensive experimental testing. This reduces capital & operating costs, lead-time-to market (development cycle) and minimizes the risks/safety concerns associated with experimental testing.

-

The ad-on benefit is that, in simulations we can include the detailed kinetics of reactions and study the impact of conditions, parameters on the product yields or desired v/s undesired reactions.

-

These simulations can be performed by an engineer (skilled in CFD-DEM) virtually on a computer hardware and if required from remote locations, on remote platforms.

-

These simulations can also be used to troubleshoot and solve issues that may arise during reactor operation. This can help in preventing costly downtime and ensure that the reactor operates at peak efficiency.

Challenges and Limitations of CFD-DEM in Catalyst-Particles

While CFD-DEM simulations offer numerous benefits, there are also several challenges and limitations associated with their use.

-

One of the primary challenges is the computational complexity of these simulations. Particle resolved CFD-DEM simulations are numerically complex, require significant computational resources and time, particularly for the large-scale reactors with a high number of particles. This can limit the accessibility and feasibility of these simulations for some applications.

-

Another challenge is the accuracy of the simulations; which is highly dependent on (1) the quality of the input data, such as physical & thermal properties of fluid and particles, (2) the assumptions made during CFD-DEM modelling and (3) accuracy of the experimental data against which simulation model needs to be tuned.

Despite these challenges, the benefits of CFD-DEM simulations often outweigh the limitations, particularly when it comes to optimizing packed bed reactors and enhancing reactor performance. By addressing the challenges and limitations, engineers can maximize the effectiveness of CFD-DEM simulations and unlock their full potential.

Future Trends in CFD-DEM and Packed Bed Reactor Technology

The future of CFD-DEM and packed bed reactor technology is bright, with several emerging trends and advancements that have the potential to further enhance reactor performance and efficiency. One of the most significant trends is the integration of machine learning and artificial intelligence (AI) with CFD-DEM simulations. By leveraging the power of AI, engineers can automate the optimization process and identify the most efficient reactor designs and operating conditions more quickly and accurately.

Another emerging trend is the use of advanced materials and catalyst particles in packed bed reactors. By developing new materials with enhanced properties, engineers can further improve the effectiveness of the catalyst particles and enhance reactor performance. For example, the use of nanomaterials and advanced coatings can enhance the surface properties of the catalyst particles, leading to improved mass and heat transfer and higher reaction rates.

Additionally, there is a growing focus on sustainability and energy efficiency in chemical engineering. By leveraging CFD-DEM simulations, engineers can develop more sustainable and energy-efficient processes, aligning with the growing demand for greener chemical engineering practices. This includes optimizing reactor design and operation to minimize energy consumption and reduce waste, as well as developing new processes and technologies that are more environmentally friendly.

Overall, the future of CFD-DEM and packed bed reactor technology is promising, with numerous advancements and trends that have the potential to further enhance reactor performance and efficiency. By staying at the forefront of these trends and leveraging the latest technologies, engineers can continue to optimize reactor design and operation, leading to more efficient and sustainable chemical engineering processes.

Best Practices for Implementing CFD-DEM in Your Processes

Implementing CFD-DEM simulations in your processes can offer numerous benefits, but it is important to follow best practices to maximize the effectiveness of these simulations. One of the most important best practices is to ensure the accuracy of the input data. This includes accurately characterizing the properties of the fluid and particles, as well as the operating conditions of the reactor.

Another best practice is to validate the simulation results with experimental data. While CFD-DEM simulations offer detailed insights into the interaction between fluid and particles, it is important to validate these results with experimental data to ensure their accuracy. This can help in tunning the model parameters & settings, identify the gaps and ensure that the simulations are providing reliable results. For example, the simulation of catalyst bed can be validated against the cold-flow experiments data on the pressure-drop versus flow. Such validation is good enough to characterize the structure and nature of catalyst particle bed.

In addition, it is important to work with experienced and knowledgeable professionals when setting up and interpreting CFD-DEM simulations. These simulations can be complex and require specialized knowledge and expertise to set up and interpret the results accurately. Working with experienced professionals can help ensure that the simulations are set up correctly and that the results are interpreted accurately.

Finally, it is important to stay up to date with the latest advancements and trends in CFD-DEM and packed bed reactor technology. By staying at the forefront of these trends and leveraging the latest technologies, engineers can continue to optimize reactor design and operation, leading to more efficient and sustainable processes.

Conclusion: The Future of Efficiency in Chemical Engineering

In conclusion, CFD-DEM simulations offer a powerful tool for optimizing packed bed reactors and enhancing reactor performance. By providing detailed insights into the structure of bed & distributions inside the bed, these simulations can help engineers optimize reactor design and operation, leading to improved reaction rates, enhanced mass and heat transfer, and higher productivity. Despite the challenges and limitations associated with CFD-DEM simulations, the benefits often outweigh the limitations, particularly when it comes to optimizing packed bed reactors.

Looking to the future, the integration of machine learning and AI with CFD-DEM simulations, the development of advanced materials and catalyst particles, and the growing focus on sustainability and energy efficiency all have the potential to further enhance reactor performance and efficiency. Ultimately, the future of efficiency in chemical engineering lies in the ability to understand and optimize the complex interactions between fluids and particles. By unlocking the full potential of CFD-DEM simulations, engineers can develop more efficient and cost-effective reactors, leading to more sustainable and productive chemical engineering processes.

Case Studies: Successful Applications of CFD-DEM

Through different case studies and solutions to industry problems, our engineers have demonstrated the effectiveness of CFD-DEM simulations in optimizing packed bed reactors and enhancing reactor performance. These case studies highlight the transformative power of this technology and its potential to revolutionize chemical engineering processes.

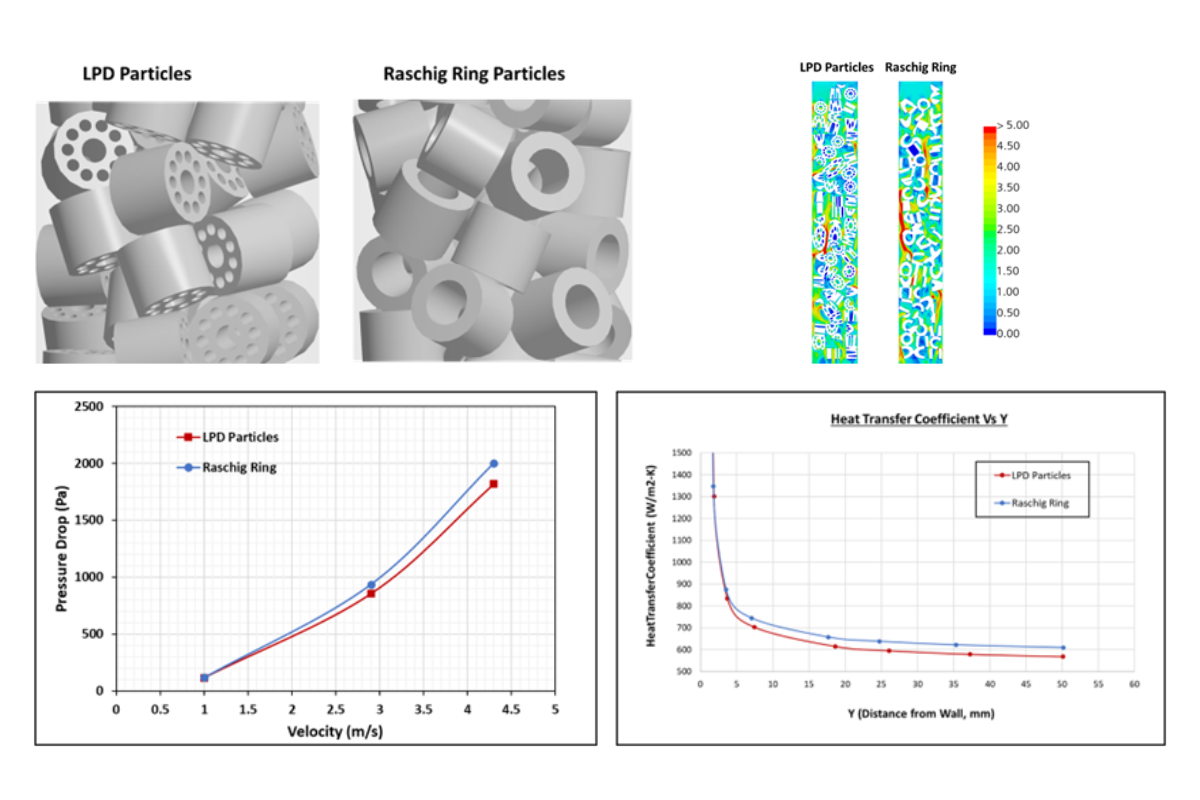

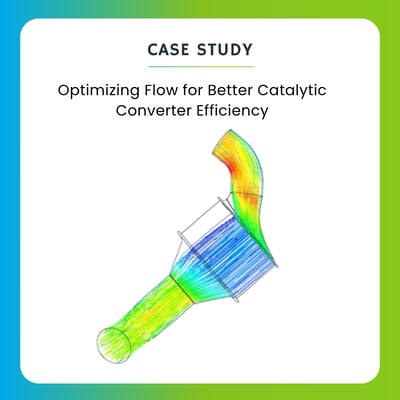

One notable case study, briefed here, involves the optimization of the shape of catalyst particles used for the steam reforming applications. By using CFD-DEM simulations, our engineers were able to study the impact of catalyst particle shape & size on the packing structure, fluid flow, pressure drop and heat transfer & reaction efficiency. The simulations revealed that catalyst size has impact on packing porosity, while shape of particles has impact on both packing porosity and reaction efficiency. For example, cylindrical particles with multiple holes have lower pressure drop but are low on the heat transfer & reactions performance. While the rasching rings particles are high on pressure drop but are better in the heat transfer & reaction performance. The snapshots of bed structure, flow distribution around catalyst particles and performance are shown in the Figure below

By optimizing the particle shape & size, the engineers were able to significantly enhance the reaction rates and overall efficiency of the reactor.

Another case study involves the use of CFD-DEM simulations to optimize a packed bed reactor used for hydrogenation. The simulations revealed that the shape and size of the catalyst particles were impacting the effectiveness of the reaction. By optimizing the particle size and shape, engineers were able to enhance the mass and heat transfer within the reactor, leading to improved reaction rates and productivity.

A third case study involves the use of CFD-DEM simulations to troubleshoot a packed bed reactor used for gas absorption. The simulations revealed that the fluid flow was uneven, leading to areas of stagnant fluid and reduced absorption rates. By optimizing the fluid flow and reactor design, engineers were able to enhance the absorption rates and overall efficiency of the reactor.

These case studies demonstrate the effectiveness of CFD-DEM simulations in optimizing packed bed reactors and enhancing reactor performance. By providing detailed insights into the behavior of fluids and particles, CFD-DEM simulations offer a powerful tool for improving reactor design and operation, leading to more efficient and cost-effective processes.

Technical Contributor

Mr. Tukaram Suryawanshi

Head of Process Consulting

Tridiagonal Solutions

Related Use Cases

Blogs

Boosting Cement Industry Efficiency with Advanced CAE Simulations

Blogs

Fluid Structure Interaction Analysis (FSI): Maximizing Efficiency and Safety in...

Use Cases

Flow Distribution in Catalytic Converter

Use Cases

Simulating Data Centers using CoolSim

Have a Question?

If you need assistance beyond what is provided above, please contact us.