Static mixers (SMX) are compact and efficient devices, but they often face challenges such as ensuring uninterrupted mixing of viscous liquids, achieving uniform blending, and maintaining effective heat and mass transfer. To address these, CFD simulations were carried out to evaluate flow patterns and particle distribution in SMX mixers.

The study compared two SMX designs with different diameters, providing clear insights into mixing performance and helping identify the most suitable configuration. Discover how CFD guided the selection of the optimal mixer design in this case study.

-1.png?width=342&height=168&name=Static%20Mixer%20(2)-1.png)

Related Use Cases

Use Cases

Evaluating Crude Oil Blending with Jet-Mixers using CFD

Use Cases

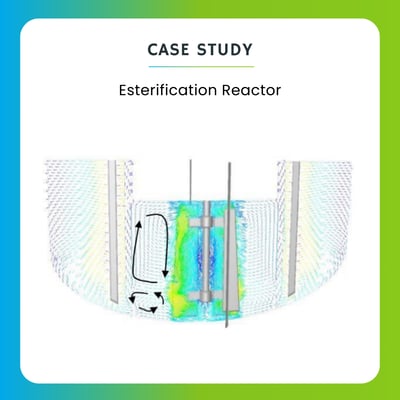

Esterification Reactor

Use Cases

CFD–FEA Coupled Simulation to Resolve Tube Failure in Oxygen Mixing Device

Use Cases

Mixing Studies

Have a Question?

If you need assistance beyond what is provided above, please contact us.