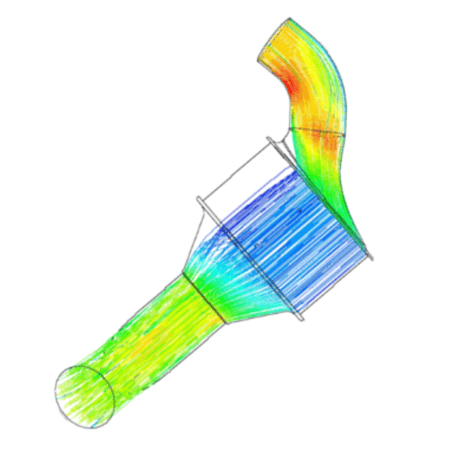

Enhancing the efficiency and durability of catalytic converters and combustion systems is critical for optimal plant performance. This case study showcases how Computational Fluid Dynamics (CFD) was used to improve flow distribution in catalytic converters, leading to better pollutant conversion. It also highlights the role of detailed combustion modeling in minimizing thermal stresses and preventing tube failures—ultimately reducing shutdowns and improving operational reliability.

Download the full case study to explore how CFD-driven insights helped optimize burner configurations, improve flame stability, and extend equipment life. Gain a deeper understanding of how simulation can be a powerful tool in solving real-world challenges in emissions control and thermal system design.

Related Use Cases

Use Cases

Simulating Data Centers using CoolSim

Blogs

How CFD-DEM Revolutionizes Catalyst-Particles in Packed Bed Reactors

Blogs

Boosting Cement Industry Efficiency with Advanced CAE Simulations

Blogs

Fluid Structure Interaction Analysis (FSI): Maximizing Efficiency and Safety in...

Have a Question?

If you need assistance beyond what is provided above, please contact us.