- What is Computer-Aided Engineering (CAE)?

- Why CFD is Crucial for the Cement Industry?

- Key Applications of CFD in Cement Plant

- Future Trends in CFD for Cement Manufacturing

- Explore Real Cement Industry Case Studies: Download Brochure

- The Importance of Engaging a CFD Consultant for Your Cement Plant Projects | Tridiagonal Solutions

In today’s cement manufacturing landscape, improving efficiency and sustainability is no longer optional - it’s essential. Computer-Aided Engineering (CAE) simulation technologies, including Computational Fluid Dynamics (CFD) and other advanced modeling tools, are proving to be powerful enablers of this transformation. These technologies allow manufacturers to optimize plant operations, reduce energy consumption, and improve product quality with greater accuracy. By leveraging integrated CAE analysis, cement plants can streamline complex processes, minimize operational bottlenecks, and drive consistent performance. This article explores how CAE simulations are unlocking new opportunities to optimize cement plant performance while supporting a more sustainable future for the construction industry.

What is Computer-Aided Engineering (CAE)?

Computer-Aided Engineering (CAE) refers to the use of advanced computer simulations to support engineering analysis and design. Instead of relying only on physical prototypes, CAE helps engineers virtually test and improve products, processes, and systems, reducing costs and saving time. It plays a vital role in industries such as energy, automotive, aerospace, and electronics where performance, efficiency, and safety are critical.

Within CAE, several specialized methods are widely used:

- Computational Fluid Dynamics (CFD) : Analyzes fluid flow, heat transfer, and mixing processes.

- FEA Finite Element Analysis (FEA) : Studies how structures and components respond to stresses, loads, and vibrations.

- Discrete Element Method (DEM): Models the flow and behavior of bulk solids and granular materials.

- Multiphysics Simulations: Combine different methods (CFD, FEA, DEM, etc.) to capture complex real-world interactions.

Beyond product and process design, CAE also enables data-driven decision-making, where simulation results are integrated with plant data, AI, and digital twins. This empowers industries to move toward predictive maintenance, reduced downtime, and sustainable operations—making CAE not just a design tool, but a strategic enabler of innovation and competitiveness.

Why CFD is Crucial for the Cement Industry?

The cement industry is highly energy-intensive, with processes involving high temperatures, complex multiphase flows, and stringent environmental regulations. Small inefficiencies in equipment such as rotary kilns, calciners, cyclones, or filters can lead to increased fuel consumption, higher emissions, and reduced product quality.

One of the primary reasons CFD is crucial for the cement plant is its ability to predict and control the behavior of gases and particles within the manufacturing process. For instance, the calcination process in a cement kiln involves complex chemical reactions and heat transfer mechanisms. CFD can simulate these processes in detail, allowing engineers to identify hotspots, optimize burner designs, and improve fuel efficiency. This leads to reduced energy consumption and lower greenhouse gas emissions.

Traditional approaches, like rule-of-thumb design or empirical models - often fall short in capturing the complex physics of cement manufacturing. CFD bridges this gap by enabling:

- Process optimization without extensive plant trials

- Accurate prediction of temperature, mixing, and flow profiles

- Troubleshooting persistent bottlenecks in equipment

- Environmental compliance by simulating pollutant formation and control strategies

In essence, CFD empowers the cement industry to achieve higher efficiency, lower costs, and better product quality through virtual experimentation and optimization.

Key Applications of CFD in Cement Plant

CFD has a wide range of applications in cement plants, each contributing to the overall efficiency and sustainability of the manufacturing process.

Rotary Kiln Optimization

The rotary kiln is the heart of cement production, but it is prone to challenges like flame instability, coating formation, and uneven temperature distribution. CFD helps in:

- Optimizing burner design and fuel injection

- Understanding combustion dynamics to reduce NOx and CO emissions

- Improving heat transfer to ensure uniform clinker formation

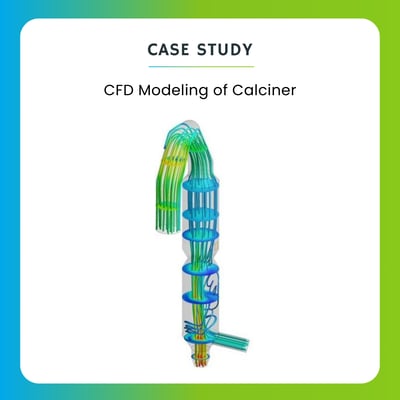

Calciner Performance Improvement

Calciners handle fuel combustion and raw meal decomposition at high temperatures. CFD simulations enable:

- Analysis of fuel-air mixing and residence time

- Reduction of unburned carbon losses

- Strategies for lowering NOx generation by staging combustion zones

- To analyse the calcination process and hence compute the efficiency of meal decomposition.

Cyclone Separator Efficiency

Cyclones are critical for raw meal preheating and dust collection. Inefficient designs can lead to pressure losses and poor separation efficiency. CFD provides insights into:

- Gas-solid flow patterns

- Particle collection efficiency under varying loads

- Design modifications to reduce pressure drop and improve thermal efficiency

Electrostatic Precipitator (ESP) Flow Distribution

Non-uniform gas flow at the ESP inlet can compromise dust collection performance. CFD helps in:

- Identifying maldistribution zones

- Redesigning inlet ducts for even flow

- Enhancing overall particulate removal efficiency

Bag Filter Flow Optimization

Bag filters are widely used for emission control. CFD assists in:

- Optimizing flow distribution at the inlet plenum

- Preventing localized dust loading that shortens bag life

- Ensuring consistent pressure drop across the filter bank

Future Trends in CFD for Cement Manufacturing

The future of CFD in cement manufacturing is promising, with several emerging trends set to revolutionize the industry. One of the key trends is the integration of artificial intelligence (AI) and machine learning (ML) with CFD simulations. By leveraging AI and ML algorithms, engineers can analyze vast amounts of simulation data, identify patterns, and make predictive decisions. This enables real-time optimization of processes, leading to further improvements in efficiency and sustainability.

The Importance of Engaging a CFD Consultant for Your Cement Plant Projects | Tridiagonal Solutions

Engaging a CFD consultant can be a game-changer for your cement plant projects. While in-house CFD capabilities are valuable, working with an experienced consultant like Tridiagonal Solutions can bring additional expertise, resources, and insights to your projects. CFD consultants have a deep understanding of fluid dynamics, heat transfer, and chemical reactions, enabling them to create accurate and reliable simulations tailored to your specific needs.

The key advantage of engaging a consultant is specialized knowledge and cross-industry experience. Having solved complex problems across cement plants worldwide, we bring tested strategies and innovative ideas to optimize processes faster and more cost-effectively than trial-and-error approaches. From rotary kiln combustion and calciner performance to cyclone efficiency, ESP flow distribution, and bag filter optimization, consultants can quickly pinpoint issues and deliver practical improvements.

At Tridiagonal Solutions, we go beyond generating simulation data, we deliver actionable, plant-ready solutions. Our team works closely with your engineers to ensure results are practical, measurable, and aligned with your operational goals. Get in touch with Tridiagonal Solutions for expert guidance on applying CFD in your cement plant.

Technical Contributor

Mr. Harinarayanan Nagarajan

Project Manager | CFD Consulting

Tridiagonal Solutions

Related Use Cases

Blogs

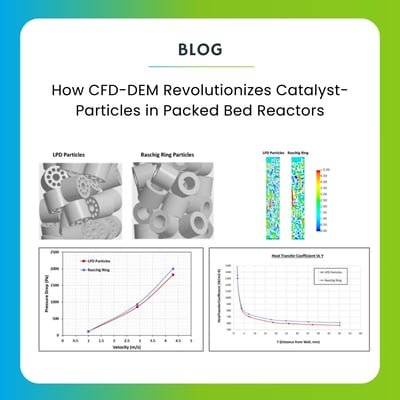

How CFD-DEM Revolutionizes Catalyst-Particles in Packed Bed Reactors

Use Cases

CFD Modeling of Bag Filter

.gif?length=400&name=Shree%20Blog%20Templates%20TSPL%20(4).gif)

Use Cases

FEA of Sheet Metal Forming

Use Cases

CFD Modeling of Calciner

Have a Question?

If you need assistance beyond what is provided above, please contact us.