Discover how advanced simulation helped eliminate wrinkles and tearing in complex sheet metal forming

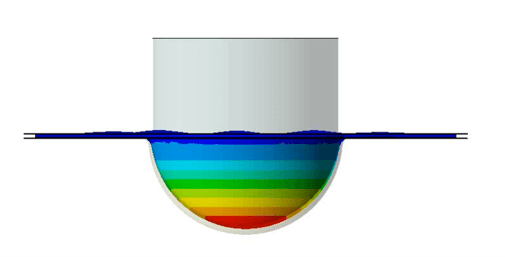

Stamping of sheet metal is a highly nonlinear and intricate process involving large deformations, contact interactions, and potential material failure. Ensuring proper die design and forming parameters is critical for optimal results.

In this case study, Tridiagonal’s Finite Element Analysis (FEA) experts leveraged ANSYS LS-DYNA to simulate the real-world forming operation with precision. The team modeled the complete system, including:

-

Blank holder force application through simulation

-

Accurate friction behavior between blank, die, punch, and holder

-

Realistic representation of material flow and deformation

This analysis allowed for early detection of defects like wrinkling and tearing, improving die design and reducing trial-and-error on the shop floor.

Download the full case study to see how simulation-driven forming helped improve product quality and process efficiency.

Related Use Cases

Use Cases

Simulating Data Centers using CoolSim

Blogs

The Evolution of CFD: A Journey of Innovation, Integration, and Impact

Use Cases

Flow Distribution in Catalytic Converter

Use Cases

Designing & Developing Air-Oil Filter for Mobile Rotary Compressor

Have a Question?

If you need assistance beyond what is provided above, please contact us.