Understanding the interaction between rollers and tubing is critical for efficient peristaltic pump operation. At Tridiagonal Solutions, we leveraged non-linear structural (FEA) and CFD simulations to capture tubing deformation, pinch points, and fluid flow behavior.

Through Design of Experiments (DoE), we characterized the operational space across varying fluid properties, RPMs, and tubing sizes. The study highlights tubing stress distribution, displacement, and flow dynamics, enabling engineers to make informed design and operational decisions. Download the full case study to explore how advanced simulation techniques can enhance pump design and efficiency.

Related Use Cases

Brochure

Erosion of Elbow and other pipe component Testing Facility

Use Cases

Paraffin Wax Stripping in Field-Scale Pipelines

Use Cases

Designing & Developing Air-Oil Filter for Mobile Rotary Compressor

Blogs

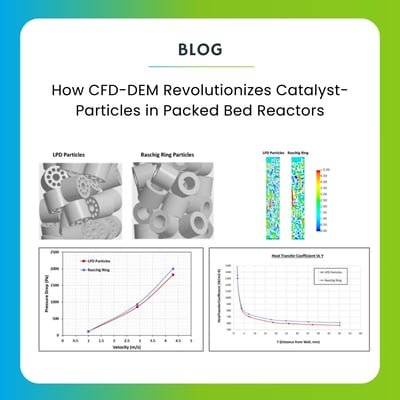

How CFD-DEM Revolutionizes Catalyst-Particles in Packed Bed Reactors

Have a Question?

If you need assistance beyond what is provided above, please contact us.