Efficient grain drying is critical to maintaining grain quality, shelf life, and storage safety in large-scale silo operations. In this case study, Computational Fluid Dynamics (CFD) is used to model the drying behavior of grains inside a silo, providing detailed insight into airflow distribution, heat and mass transfer, and moisture removal across the grain bed.

The CFD model enables prediction of drying time and identifies non-uniform drying zones within the silo. By analyzing airflow requirements and process parameters, the study supports the design of an optimized drying strategy that ensures uniform moisture reduction throughout the grain bed, improving process efficiency and product quality.

Download the complete case study to explore the CFD methodology, simulation insights, and optimization outcomes in detail.

Related Use Cases

Use Cases

Coffee Bean Dryer

.png?length=400&name=Asthma%20Inhaler%20(1).png)

Use Cases

Asthma Inhaler

Use Cases

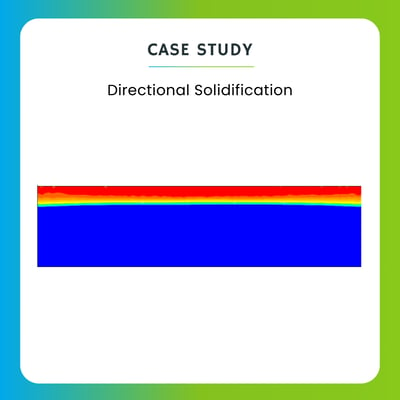

Directional Solidification

Use Cases

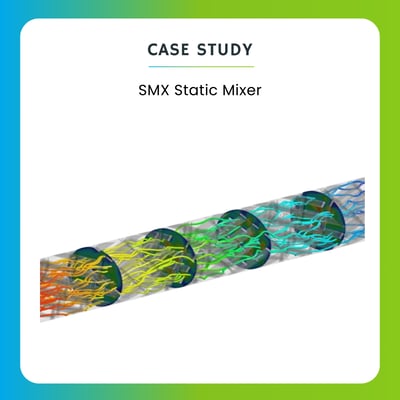

SMX Static Mixer

Have a Question?

If you need assistance beyond what is provided above, please contact us.