Controlling emissions while maintaining product quality is a key challenge in rotary kiln operations. During the combustion process in the kiln and preheat zone, high levels of NOx emissions can be generated, requiring optimization of burner design to meet environmental regulations. Using CFD simulations, combustion flame behavior, temperature distribution, kiln wall heat flux, and exit flue gas properties were analyzed.

The study provided actionable insights into how new burner designs can reduce NOx formation without compromising temperature uniformity, pellet quality, or kiln efficiency. Explore how simulation supported cleaner and more efficient rotary kiln operation in this case study.

Related Use Cases

Use Cases

Automated Inflow Control Device Erosion Test

Use Cases

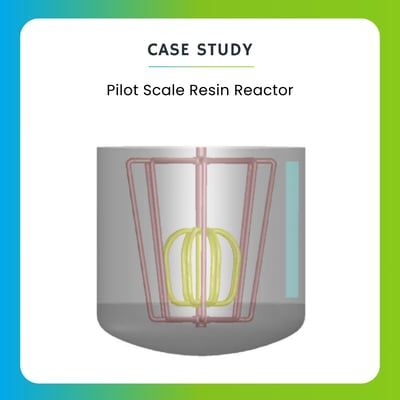

Scale-up Design of Impeller for Ion Exchange Resin Reactor

Use Cases

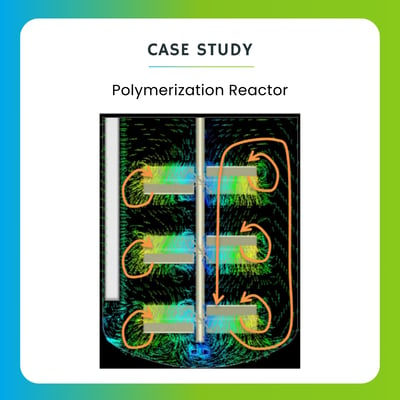

Design of Polymerization Reactor with PSD-Driven Insights

Use Cases

Sand Control Screen Erosion and Flow Performance

Have a Question?

If you need assistance beyond what is provided above, please contact us.