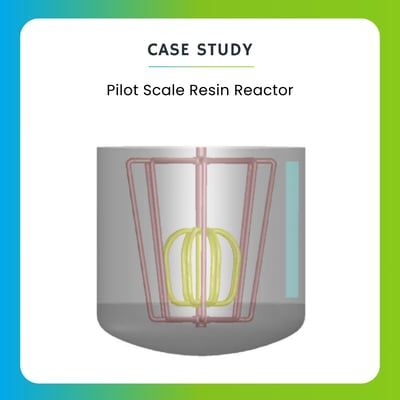

This case study highlights how CFD simulations were applied to improve the manufacturing process of ion exchange resins involving poly-dispersed bead sizes. The team analyzed the reactor’s operating conditions to understand how particle size distribution (PSD) affects strain rate distribution and mixing behavior. By simulating multiple design scenarios, it became possible to visualize performance bottlenecks and identify areas for optimization.

Through this approach, suitable design modifications were suggested that enhanced mixing uniformity, reduced localized stress, and boosted the reactor’s overall efficiency. These insights support more reliable scale-up and consistent resin quality in industrial production. Get the full case study to uncover how simulation-driven design led to measurable reactor improvements.

Related Use Cases

Use Cases

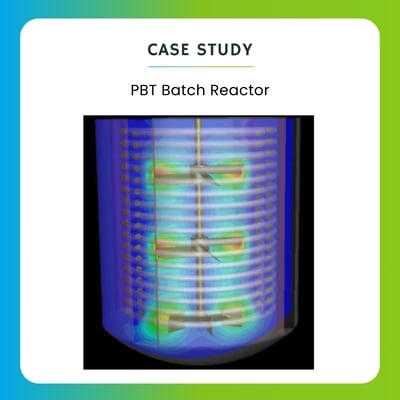

PBT Batch Reactor

Use Cases

Scale-up Design of Impeller for Ion Exchange Resin Reactor

Use Cases

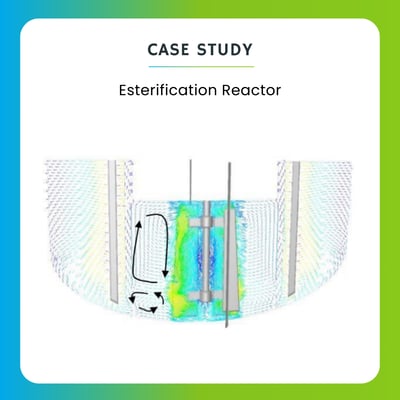

Esterification Reactor

.png?length=400&name=Main%20Final%20Temp%20CS%20(2).png)

Use Cases

Impeller Design – PSD

Have a Question?

If you need assistance beyond what is provided above, please contact us.