Scaling up from a pilot reactor to a large-scale reactor often presents challenges in maintaining performance improvements. In this study, Computational Flow Modeling (CFD) was used to compare the flow behavior, mixing patterns, and overall performance of an existing pilot-scale test reactor with that of full-scale reactor designs.

The analysis provided clarity on how design and operational differences affect scalability, enabling better transfer of pilot-scale improvements to industrial applications. Explore how simulation bridged the gap between pilot and large-scale reactor performance in this case study.

Related Use Cases

Use Cases

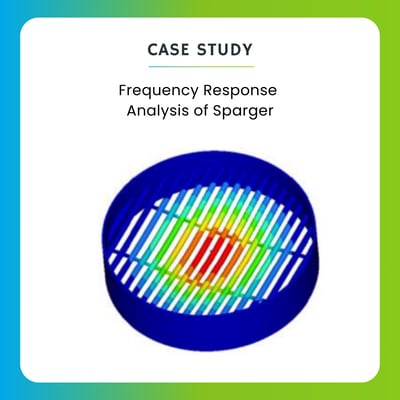

Frequency Response Analysis of Sparger

Use Cases

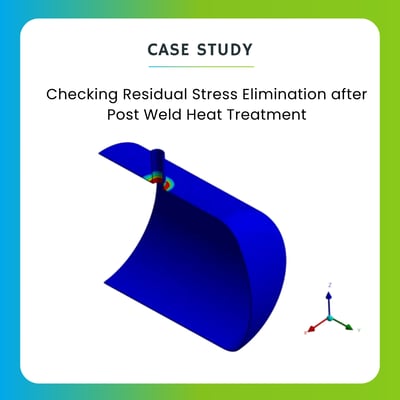

Checking Residual Stress Elimination after Post Weld Heat Treatment

Use Cases

Automated Inflow Control Device Erosion Testing Facility

.png?length=400&name=Main%20Final%20Temp%20CS%20(2).png)

Use Cases

Impeller Design – PSD

Have a Question?

If you need assistance beyond what is provided above, please contact us.