Ovalization of rotary cement kilns directly affects the structural integrity of the shell and the life of the refractory lining. Excessive ovality can cause premature refractory failure and impact overall kiln reliability. To address this, a Finite Element Analysis (FEA) was performed to evaluate the degree of ovalization in the kiln shell and benchmark it against allowable limits.

The study provided valuable insights into stress distribution and deformation, enabling preventive measures to ensure kiln stability and extend refractory life. See how FEA helped assess and control kiln ovalization in this case study.

Related Use Cases

Use Cases

Sand Control Screen Erosion and Flow Performance

Brochure

Erosion of Elbow and other pipe component Testing Facility

Use Cases

Liquid Entrainment and Jumper Study Flow Facility for Hydrate

Use Cases

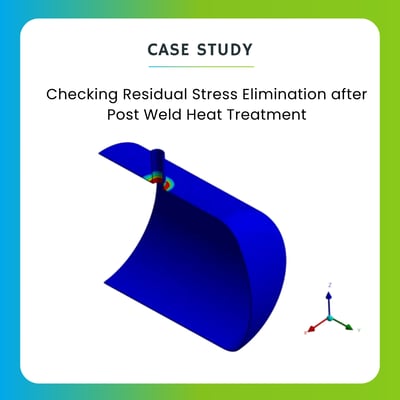

Checking Residual Stress Elimination after Post Weld Heat Treatment

Have a Question?

If you need assistance beyond what is provided above, please contact us.