Managing flow behavior in cooling sumps is critical to avoid performance losses caused by eddies, vortices, and unwanted swirl formation. Using CFD simulations, the flow distribution and vortex locations inside a multi-chamber sump were analyzed to evaluate the limitations of the existing design.

The results offered clear visualization of flow skewness and swirl patterns, enabling engineers to recommend targeted design modifications. These improvements not only reduced vortex formation but also enhanced water flow uniformity, leading to more reliable cooling performance and extended equipment life. Discover the role of CFD in optimizing sump design through this case study.

Related Use Cases

Use Cases

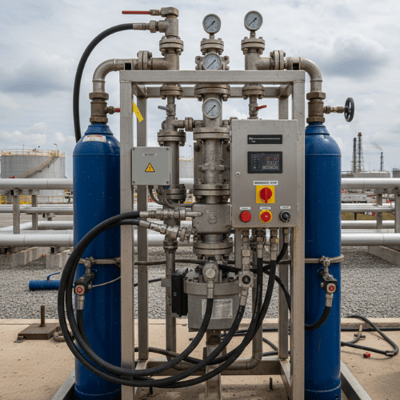

CFD–FEA Coupled Simulation to Resolve Tube Failure in Oxygen Mixing Device

Blogs

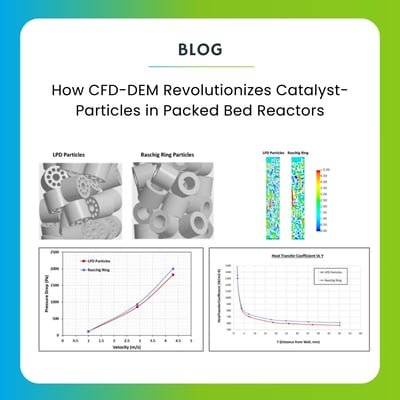

How CFD-DEM Revolutionizes Catalyst-Particles in Packed Bed Reactors

.gif?length=400&name=Shree%20Blog%20Templates%20TSPL%20(3).gif)

Use Cases

FEA to check Structural integrity of the Boiler Main Header and Stub Header

.png?length=400&name=Erosion%20Testing%20Setup%20(1).png)

Use Cases

Erosion-Corrosion Testing

Have a Question?

If you need assistance beyond what is provided above, please contact us.