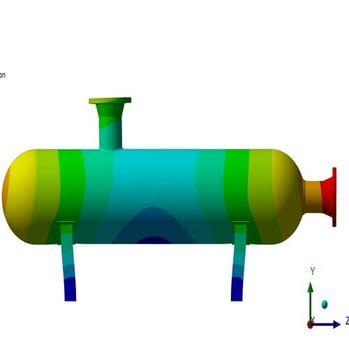

This case study presents the structural analysis of pressure vessels to ensure safe and reliable operation under varying process conditions. Using advanced simulation techniques, the vessels were evaluated for stress distribution, deformation, and safety factors against operating loads and pressure fluctuations.

The analysis helped in identifying critical stress regions, validating design integrity, and suggesting improvements for compliance with safety standards. See how structural simulation strengthened the reliability of pressure vessel design in this case study.

Related Use Cases

Use Cases

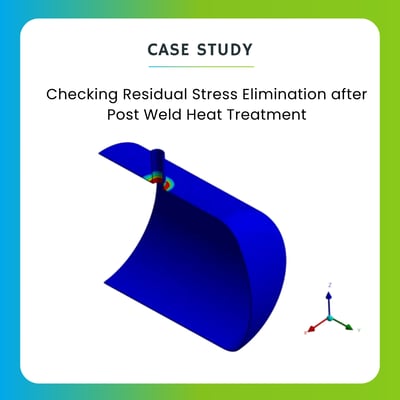

Checking Residual Stress Elimination after Post Weld Heat Treatment

Use Cases

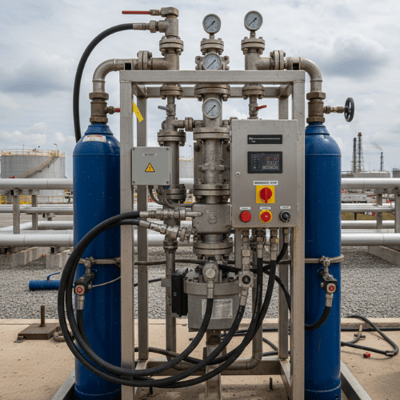

CFD–FEA Coupled Simulation to Resolve Tube Failure in Oxygen Mixing Device

Use Cases

Paraffin Wax Stripping in Field-Scale Pipelines

.webp?length=400&name=Foam%20Transportation%20Loop%20(1).webp)

Use Cases

Foam Transportation Loop

Have a Question?

If you need assistance beyond what is provided above, please contact us.