Fluid Flow Analysis

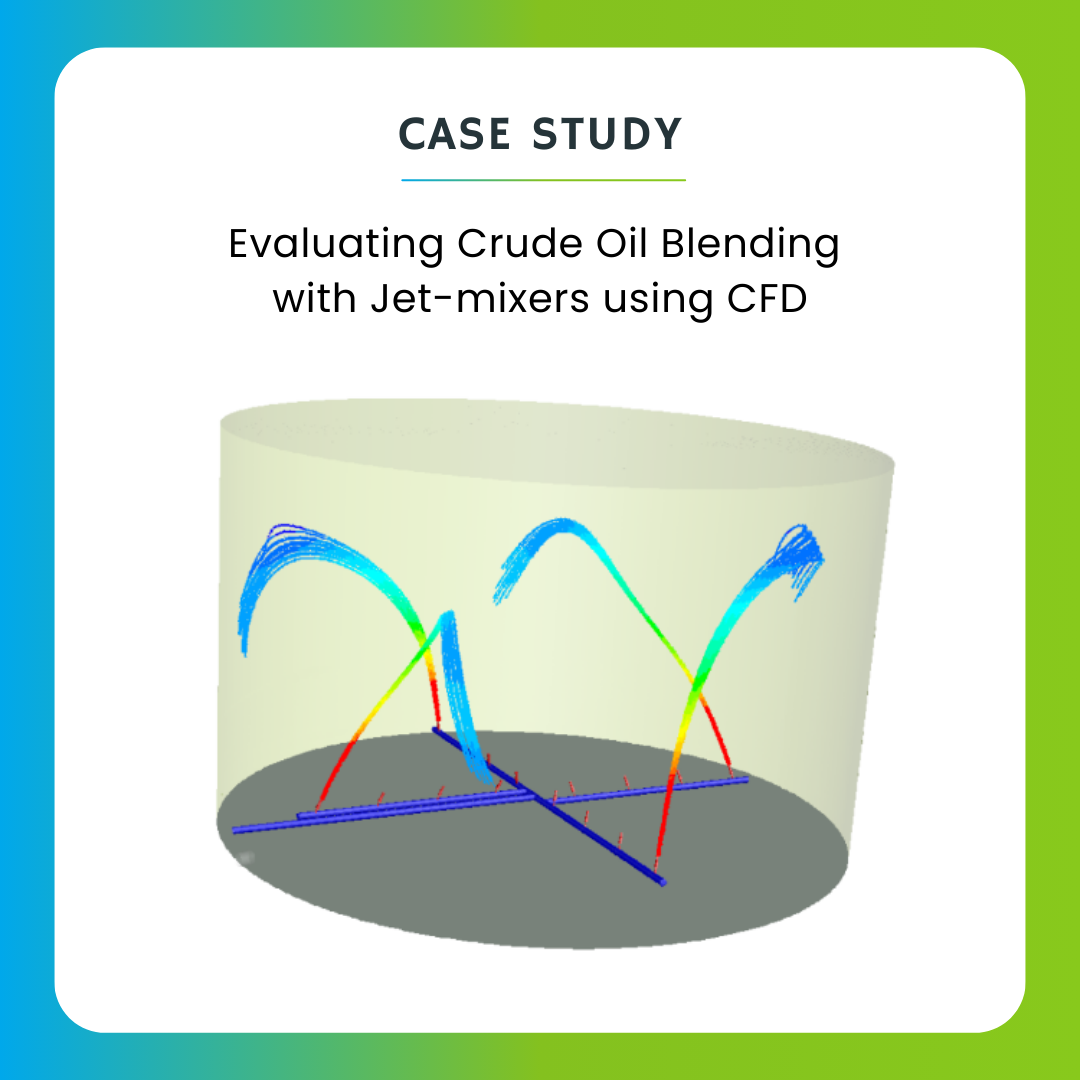

Tridiagonal engineers simulate and visualize fluid motion, pressure distribution, and forces acting on objects immersed in fluids. This helps to optimize designs for the better performance. Our engineers can simulate and analyse fluid flow around packaged goods to ensure optimal protection during transportation and storage, preventing damage and spoilage. While in Oil extraction, we simulate fluid flow during drilling to optimize wellbore placement, predict formation pressures, and ensure wellbore stability. Also we simulate the wash and cement processes to maximize the cement plug quality in Plugging and abandonment. In Process industries CFD can simulate the mixing of fluids in tanks and reactors. It can aid in scaling up processes from lab-scale to industrial-scale by simulating fluid behavior under different operating conditions and geometries. CFD models can simulate chemical reactions occurring within reactors, furnaces, and combustion chambers..

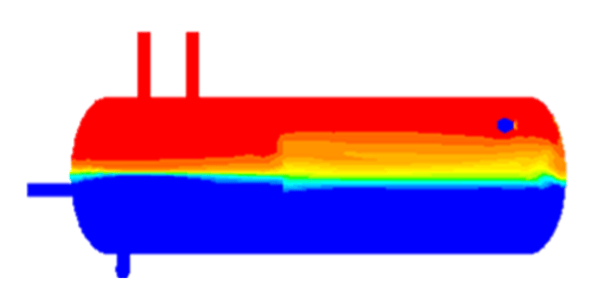

Multiphase Flow Analysis

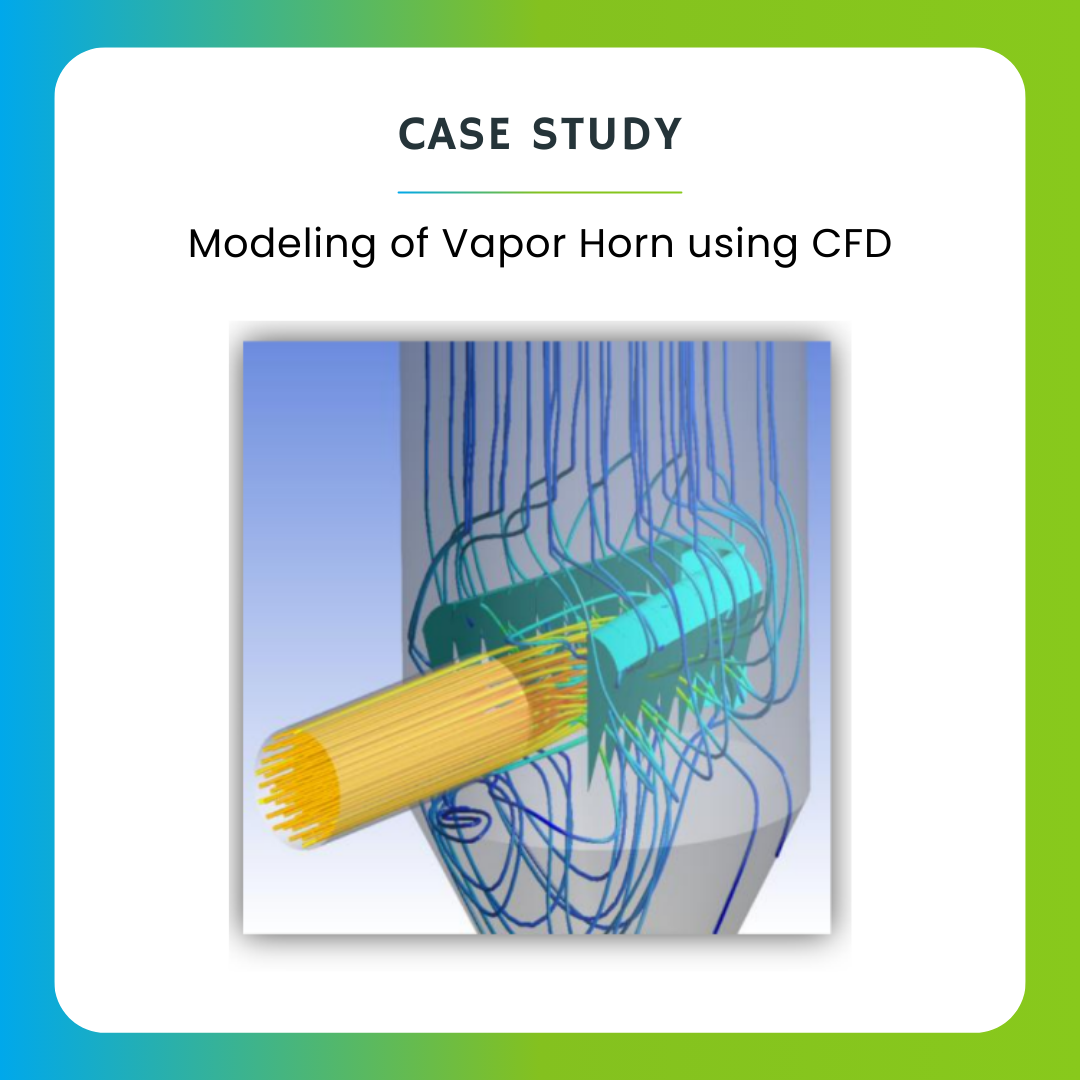

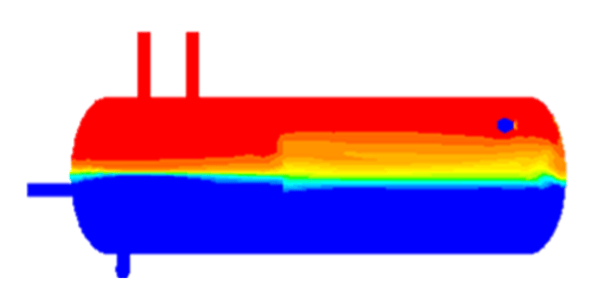

We simulate systems involving multiple fluids, solids, or gases interacting with each other. This optimizes Cyclone design, predicts behavior of slurries in pipes, and improves efficiency in separators, Knockout Drums and vapor horn.

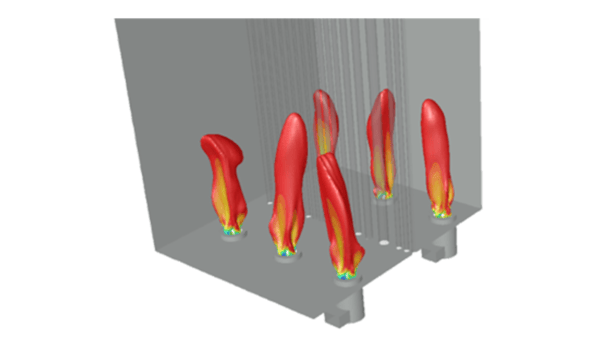

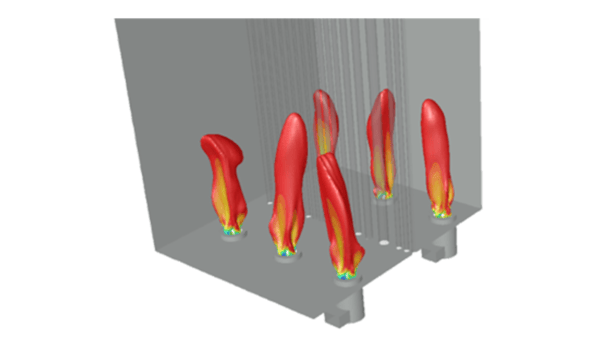

Combustion Modeling

Tridiagonal has considerable experience on modeling burner arrangements, flame interactions, NOx and SOx predictions and Flame impingement on radiant tube section to avoid rupture. Our engineers also worked on processed heaters used in reformers. We help optimize flow of fluid and air to Burner using CFD as well as improve combustion efficiency by optimizing fuel and air flow

Product Development and Innovation

CFD simulations are valuable across various industries, aiding in the design and optimization of products and processes. In the medical device industry, CFD enhances the development of inhalers, drug delivery systems, and surgical tools by simulating fluid flow, heat transfer, and particle dynamics to ensure efficiency, safety, and effectiveness.

In the chemical and process industry, it allows engineers to iterate through multiple designs and operating parameters virtually, reducing the need for costly prototypes and accelerating the development of optimized equipment. Similarly, in the CPG industry, CFD aids in the development of food products and processes, such as optimizing fluid flow and heat transfer in food extrusion and improving packaging designs to enhance product freshness and appeal. This technology streamlines development, reduces costs, and leads to better-performing products across these sectors.

CFD simulations are valuable across various industries, aiding in the design and optimization of products and processes. In the medical device industry, CFD enhances the development of inhalers, drug delivery systems, and surgical tools by simulating fluid flow, heat transfer, and particle dynamics to ensure efficiency, safety, and effectiveness.

In the chemical and process industry, it allows engineers to iterate through multiple designs and operating parameters virtually, reducing the need for costly prototypes and accelerating the development of optimized equipment.

Similarly, in the CPG industry, CFD aids in the development of food products and processes, such as optimizing fluid flow and heat transfer in food extrusion and improving packaging designs to enhance product freshness and appeal. This technology streamlines development, reduces costs, and leads to better-performing products across these sectors.

.png)