Finite Element Analysis

About Practice

Fatigue Failure Analysis

Thermal and Static Analysis

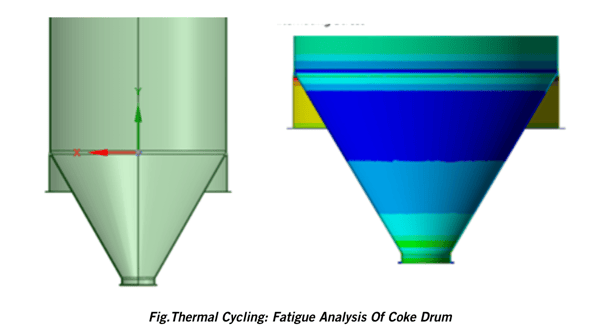

Tridiagonal FEA team can predict thermal stresses caused by temperature variations. This is important in oil and gas well casings for withstanding downhole temperature changes. In power generation, it helps analyze stress in turbine blades due to high operating temperatures. Cement kilns also benefit from our FEA's ability to predict thermal stress in refractory linings, preventing cracking and ensuring structural integrity.

FEA helps assess the structural integrity of components under static loads like pressure and weight. Our engineers are using this ability to ensure structural integrity of pressure vessels in Energy sector. Our engineers have deep knowledge of industry standards like ASME and API

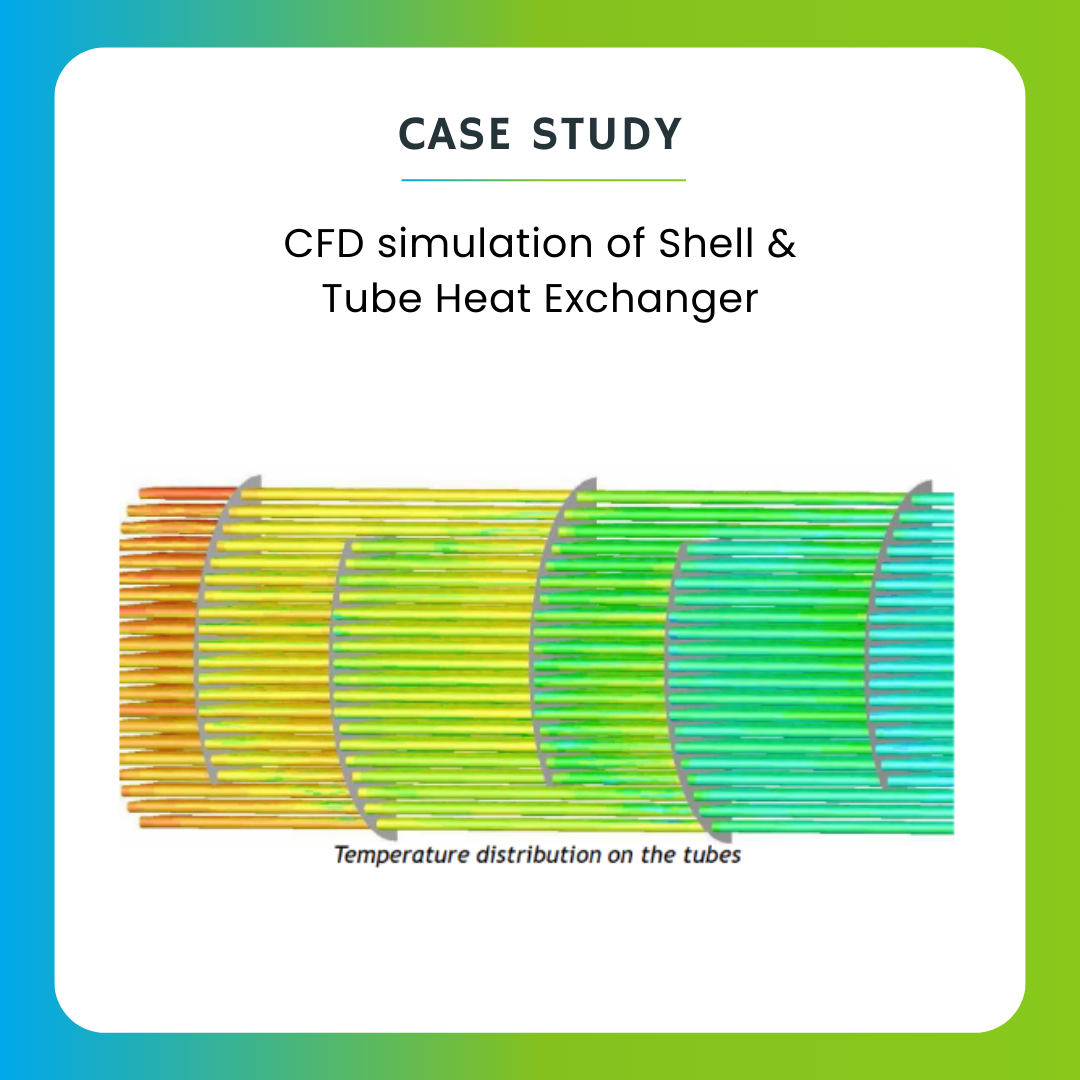

For process industries involving heat exchange, FEA can model thermal behavior, including conduction, convection, and radiation. It helps in optimizing heat exchangers, reactors, furnaces, and other thermal equipment for efficient heat transfer and temperature control.

In CPG, FEA can be utilized to analyze heat transfer phenomena in food processing equipment such as ovens, refrigerators, and pasteurizers.

Dynamic analysis and Non-linear

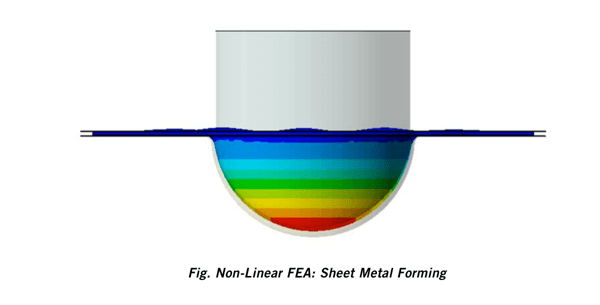

Explicit Simulation Capability : LS-DYNA

LS-DYNA is the industry’s leading explicit FEA package, featuring robust default settings, “one model, one code” reuse across physics, and optimized parallel performance. It excels in applications ranging from automotive crashworthiness and aerospace bird-strike to civil engineering seismic response and oil & gas sloshing.

Explicit simulation via LS-DYNA is indispensable wherever structural events involve rapid, severe loading and highly nonlinear geometry or materials. Its robust direct‐integration approach, coupled with industry-leading solver performance and extensive physics capabilities, makes it the gold standard for automotive, aerospace, civil, oil & gas, and manufacturing applications

Use Cases

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.

.png)