Multiphysics Simulation

About Practice

CFD-FEA Coupling

CFD–FEA coupling enables a deeper understanding of fluid–structure interaction by integrating Computational Fluid Dynamics (CFD) with Finite Element Analysis (FEA). This combined approach allows engineers to simulate how fluids influence structural performance under real-world conditions, such as pressure loads, thermal stresses, and vibration effects. By capturing both flow dynamics and structural response in a unified framework, CFD–FEA coupling provides highly accurate insights for improving design reliability, reducing failure risks, and optimizing performance across industries like aerospace, automotive, energy, and process engineering.

DEM-FEA Coupling

CFD-DEM Coupling

CFD–DEM coupling integrates Computational Fluid Dynamics (CFD) with Discrete Element Method (DEM) to accurately simulate fluid–particle interactions in complex multiphase systems. While CFD captures the behavior of the fluid phase, DEM resolves particle motion, collisions, and contact forces, enabling a detailed understanding of granular flow within fluid environments. This powerful approach is widely applied in industries such as pharmaceuticals, mining, chemicals, and energy to optimize processes like fluidized beds, pneumatic conveying, slurry transport, and mixing operations, ensuring better design efficiency, process reliability, and scale-up accuracy.

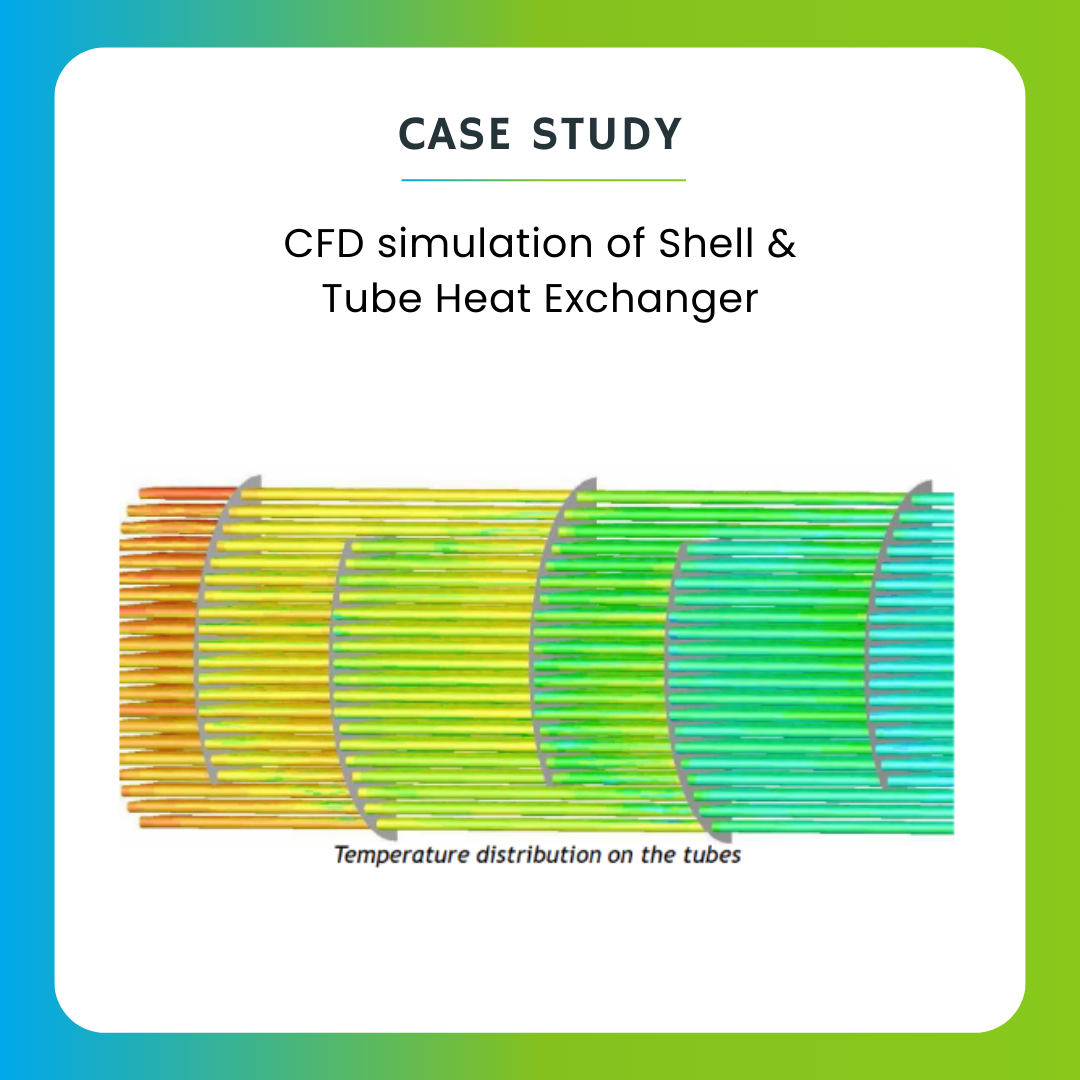

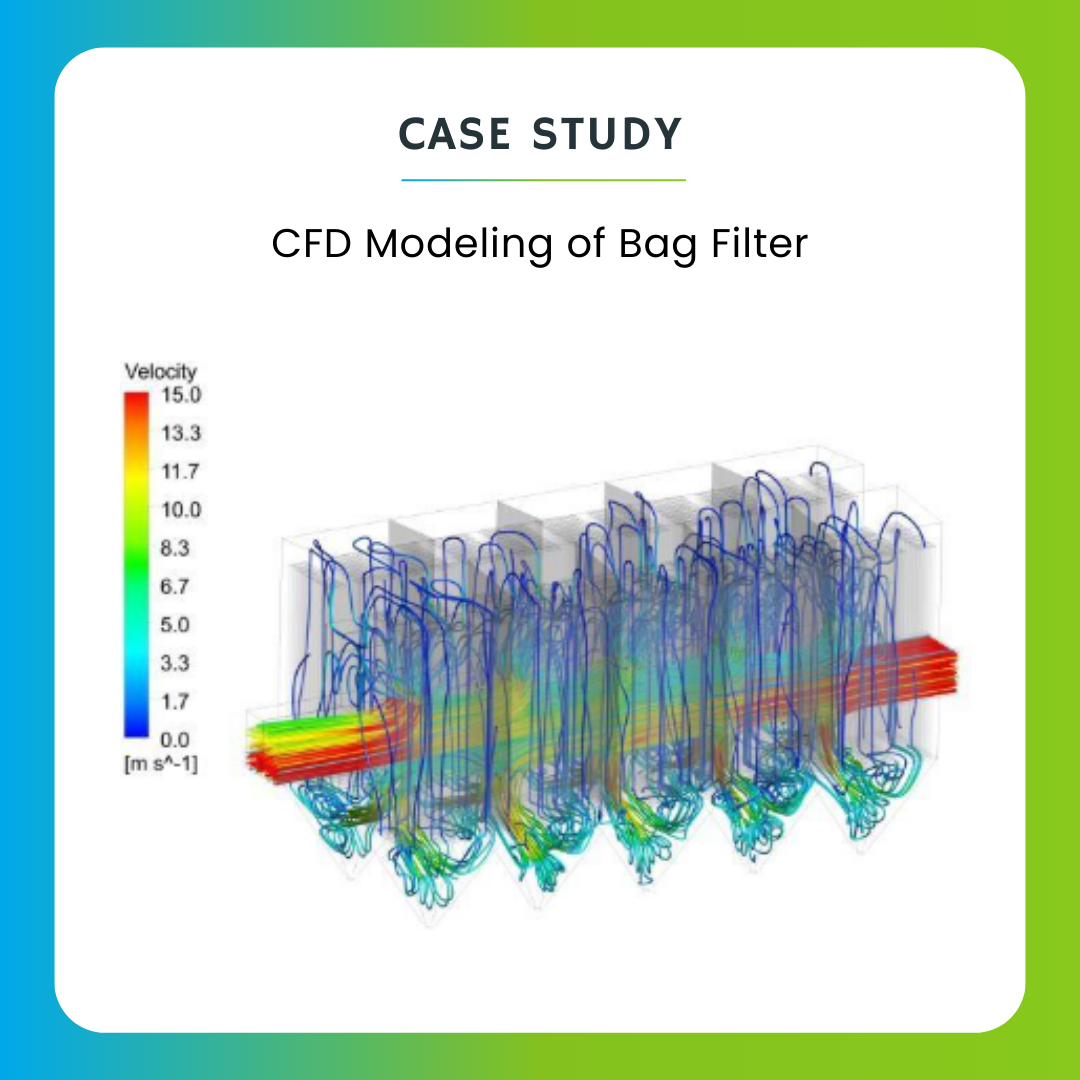

Use Cases

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.

.png)