Corrosion Testing

About Practice

We offer testing range which includes both pilot scale and lab scale corrosion testing. Pilot scale testing allows customers to evaluate corrosion inhibitors and develop models based on the actual flow behavior inside the pipeline. Lab scale testing, on the other hand, helps us test various products in a cost-effective manner. Our expertise spans diverse methodologies to evaluate material vulnerability in varied operational scenarios by conducting precise experiments.

Field Scale Corrosion Testing

- Our field scale corrosion facility offers both corrosion and erosion studies in a 4-inch pipeline at CO2 partial pressure up to 1 barg.

- It can handle the gas flow up to 1500 scfm and liquid flowrate up to 30 Nm3/hr at 10,000 ppm sand concentration.

.png?width=900&height=470&name=Field%20Scale%20Corrosion%20Testing%20(1).png)

Lab Scale Corrosion Testing

We offer the corrosion inhibition testing in various environments:

- Rotating Cage Method: The rotating cage method can be used at temperatures up to 70°C and rotation speeds up to 1000 rpm.

- Wheel Test Method: Wheel test setup can be used at temperatures up to 90°C and rotation speeds up to 20 - 90 rpm.

- Autoclave method: The autoclave design pressure and temperature can go up to 350 bar and 650°C respectively and the volume ranges from 500 ml to 25 liters.

- Jet Impingement: The impingement angle generally varies from 10°C to 90°C, impingement velocity can go up to 30 m/s. The nozzle diameter depends on the specimen and the distance between them.

.png?width=900&height=470&name=Lab%20Scale%20Corrosion%20Testing%20(1).png)

Use Cases

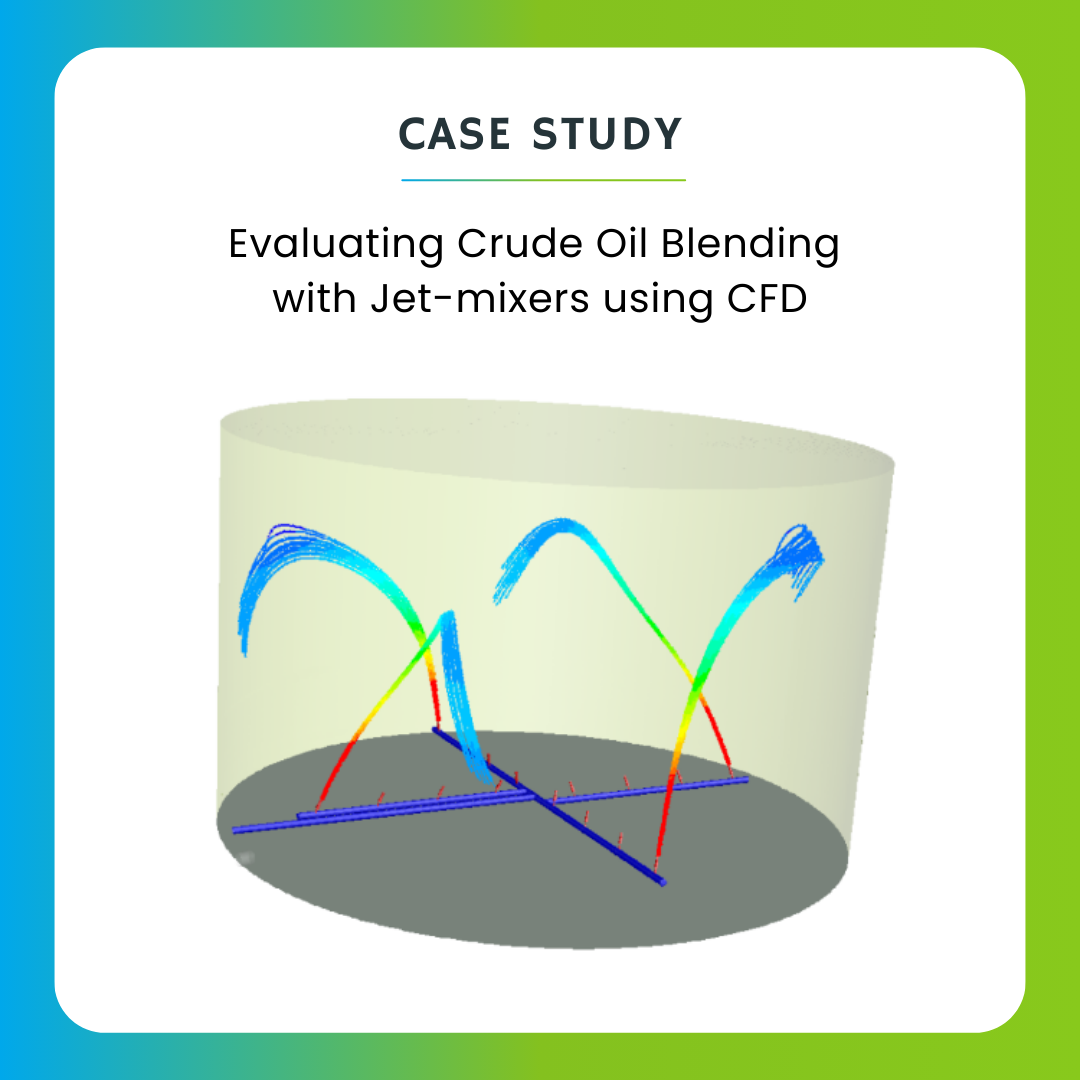

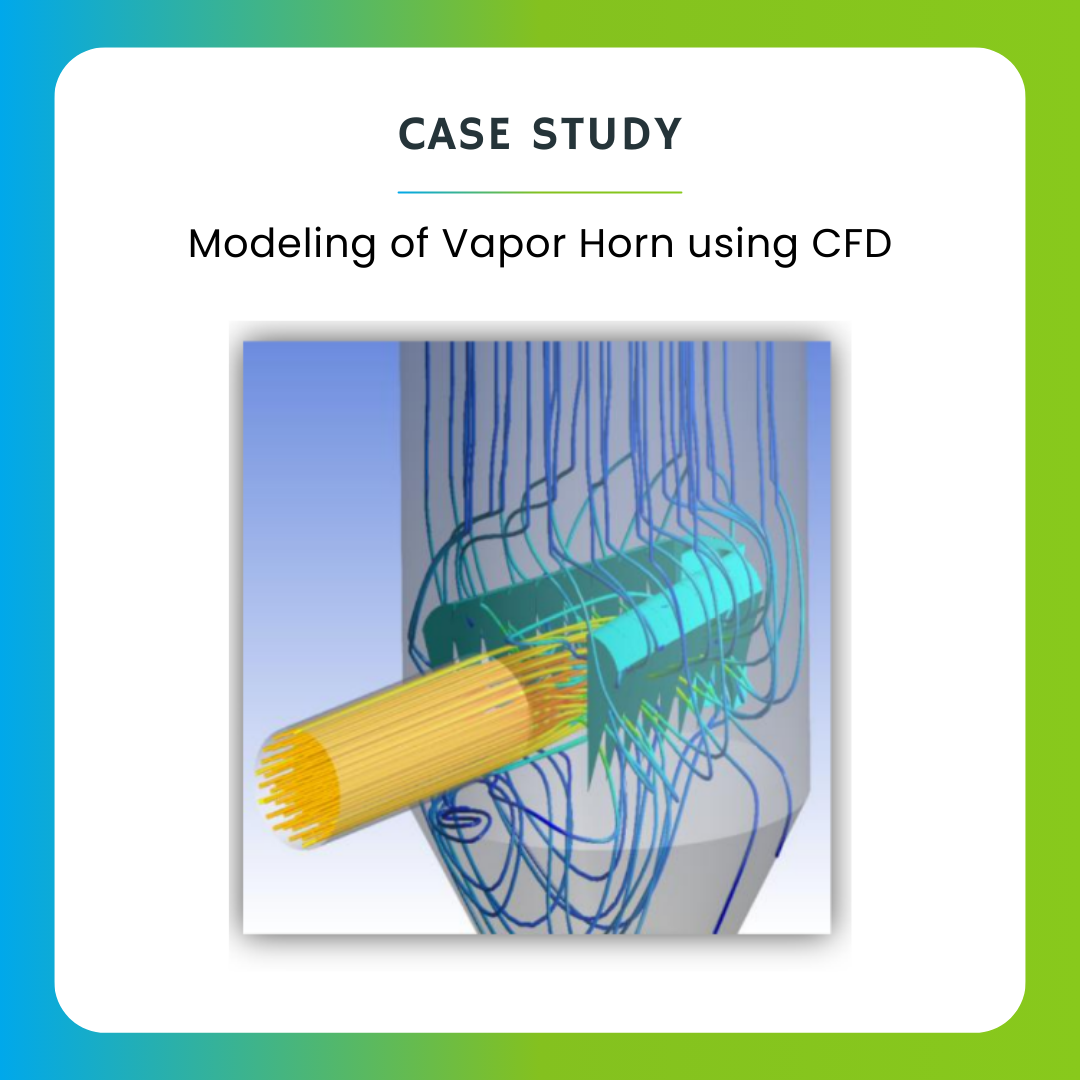

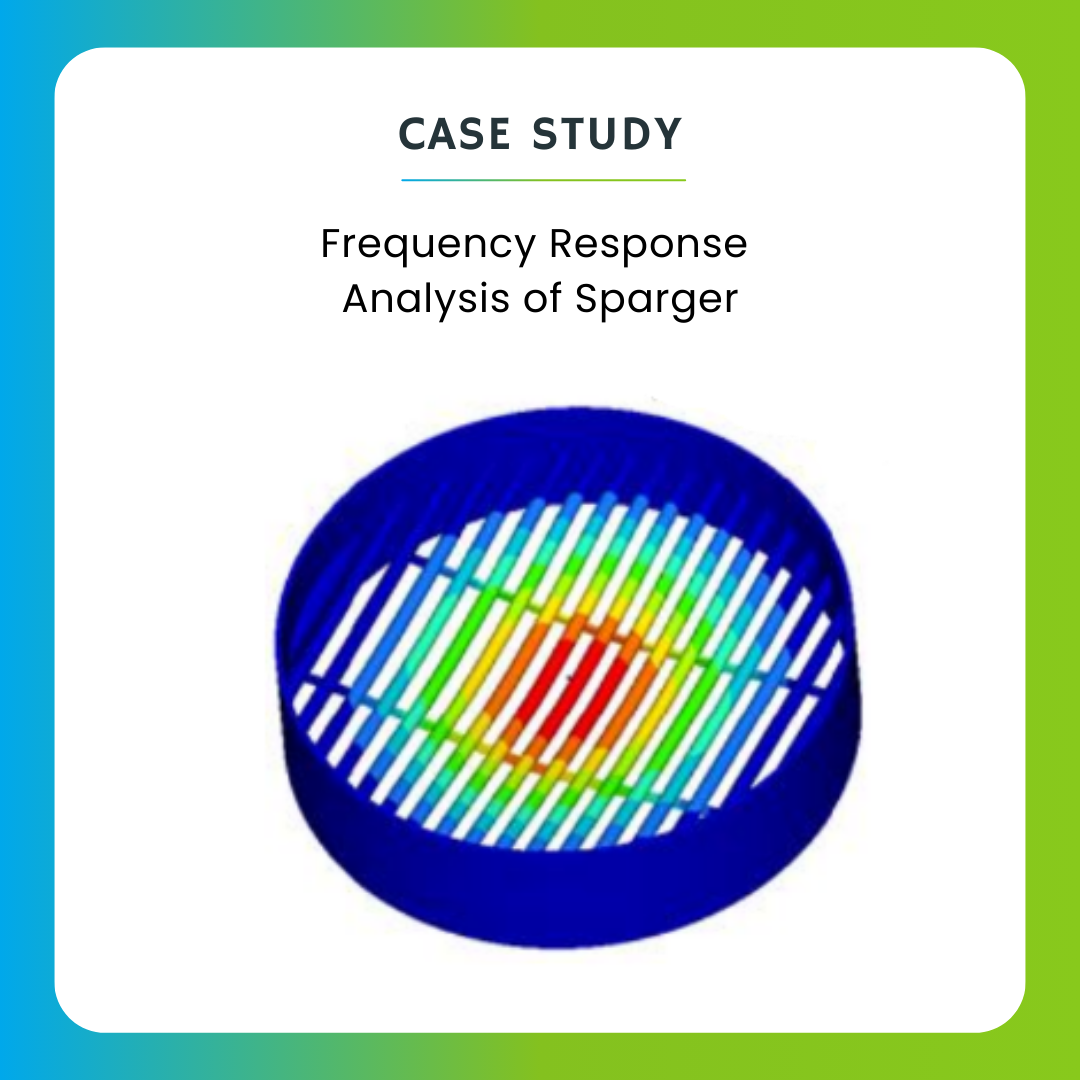

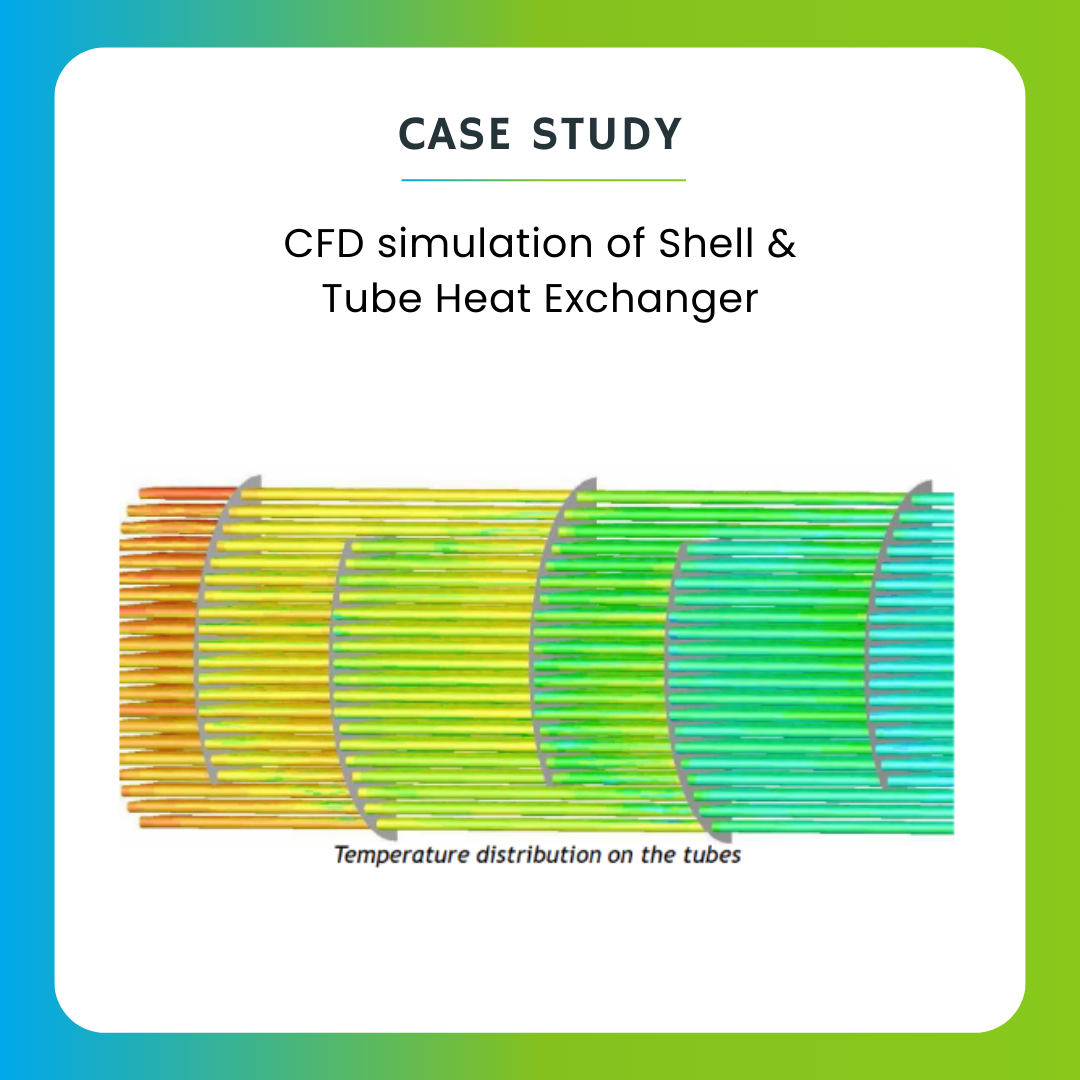

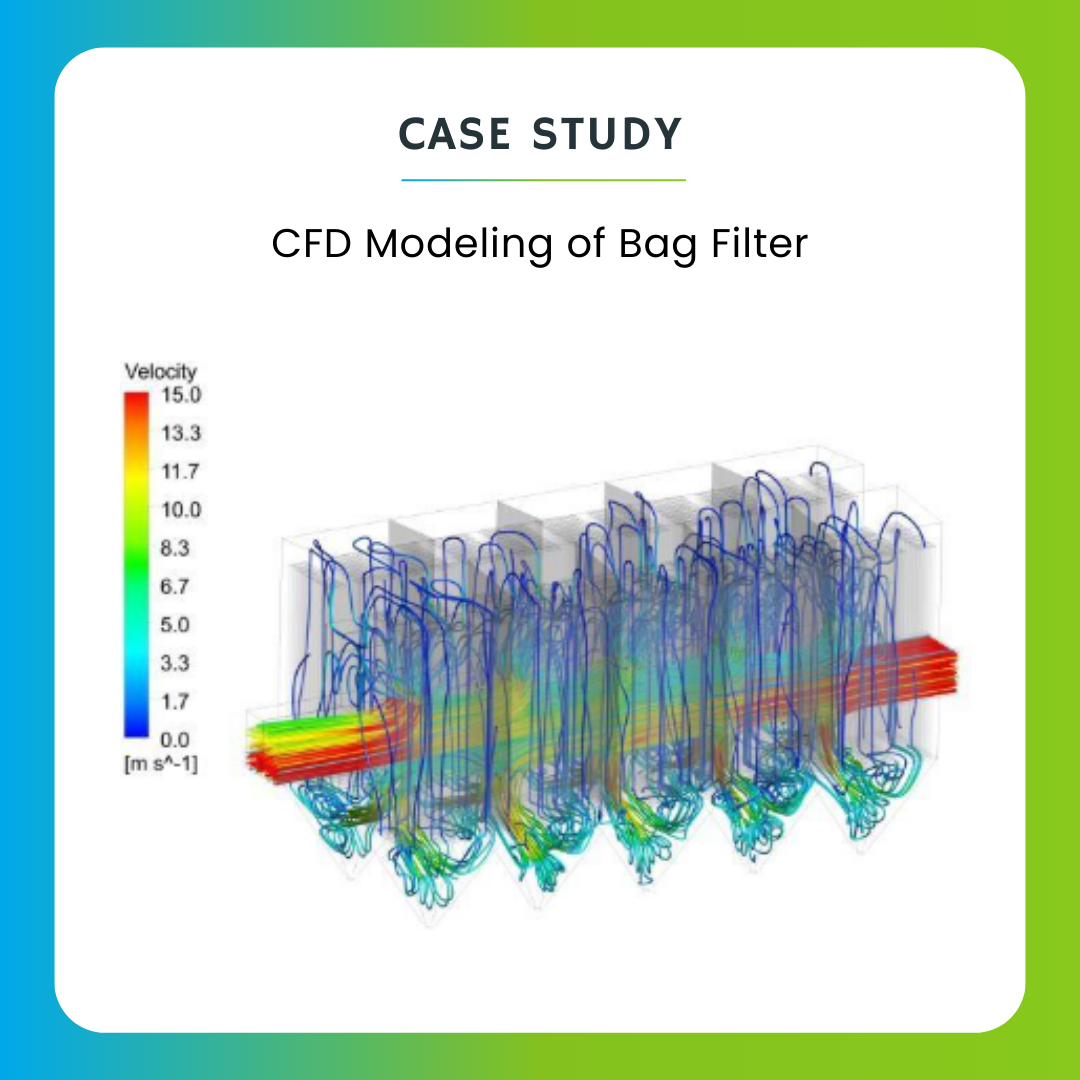

Despite of ever-evolving industries and complex value chains, digital engineering and experimental methods remain key to solving design, operational, and scale-up challenges. The following use cases highlight the application of Advanced Modeling & Simulation and Experimental Lab Scale-up in solving critical problems across diverse domains.

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.

.png)