Erosion Testing

About Practice

Our cutting-edge facilities include Screen, Elbow, Valve, and other pipeline components Erosion Testing, along with Burst Collapse, Sand Blast, Sand Retention, and Inflow Control Device Testing. Through rigorous evaluation, we ensure the durability and reliability of oil and gas production equipment in challenging environments.

Screen Erosion Testing Facility

We offer sand control screen erosion and flow performance testing for both Dry Gas and Slurry.

- Capable to operate at 70 m/s of gas superficial velocity in 4" line.

- Silica flour/sand used as erodent.

- Screen erosion assessed via weight loss, MPP (API 19 SS), microscopic, and light table images.

ICD Testing

- Conduct AICD flow performance, cavitation and erosion test.

- Plugging Test as per API 19 ICD.

- Capable to operate at high pressure of 150 bar with multiphase & single-phase flow, even with high-viscosity fluids

Sand Retention Testing

.jpg?width=900&height=618&name=Sand%20Retention%20Testing%20(1).jpg)

- Evaluates sand screen effectiveness and performs slurry and sand pack testing.

- It utilizes a 2" screen holder, flow of 100-5000 ml/min, up to 1000 psig.

- Slurry tests range from 1000 to 5000 ppm concentration.

- Deliverables include flow, pressure data, PSDs, and master curves.

Elbow Testing Facility

Major pipeline erosion occurs at elbows, tees, and reducers. We offer:

- Field-Scale Testing: 30m pipeline length.

- Variety of Pipe Sizes: From 1" to 8".

- High Flow Rates: Up to 2200 SCFM for gas, 150 Nm³/h for water.

Valve Erosion Testing Facility

Our facility offers control valve erosion study at field condition:

- Evaluate and monitor erosion rate and profile of valves in 1”to 4”.

- Perform test at high temperatures, pressure and flow rate with a constant sand feeding rate.

Sand Blast Facility

- Sand blast testing evaluates steel specimen coatings in a sand impingement cell.

- Assess coating thickness loss via weight and thickness gauge.

- Allows airflow (10-50 m/s), particle size (> 100 μm), sand rate (> 1 Kg/h), and impingement angle (0-90o) variations.

Burst Collapse Facility

- Determine the burst and collapse pressure rating of sand screen as per API 19SS.

- Conduct test up to (but not limited to) 1000 bar.

- Formulation of Fluid Loss Control pill and Provision for Push – off test.

Use Cases

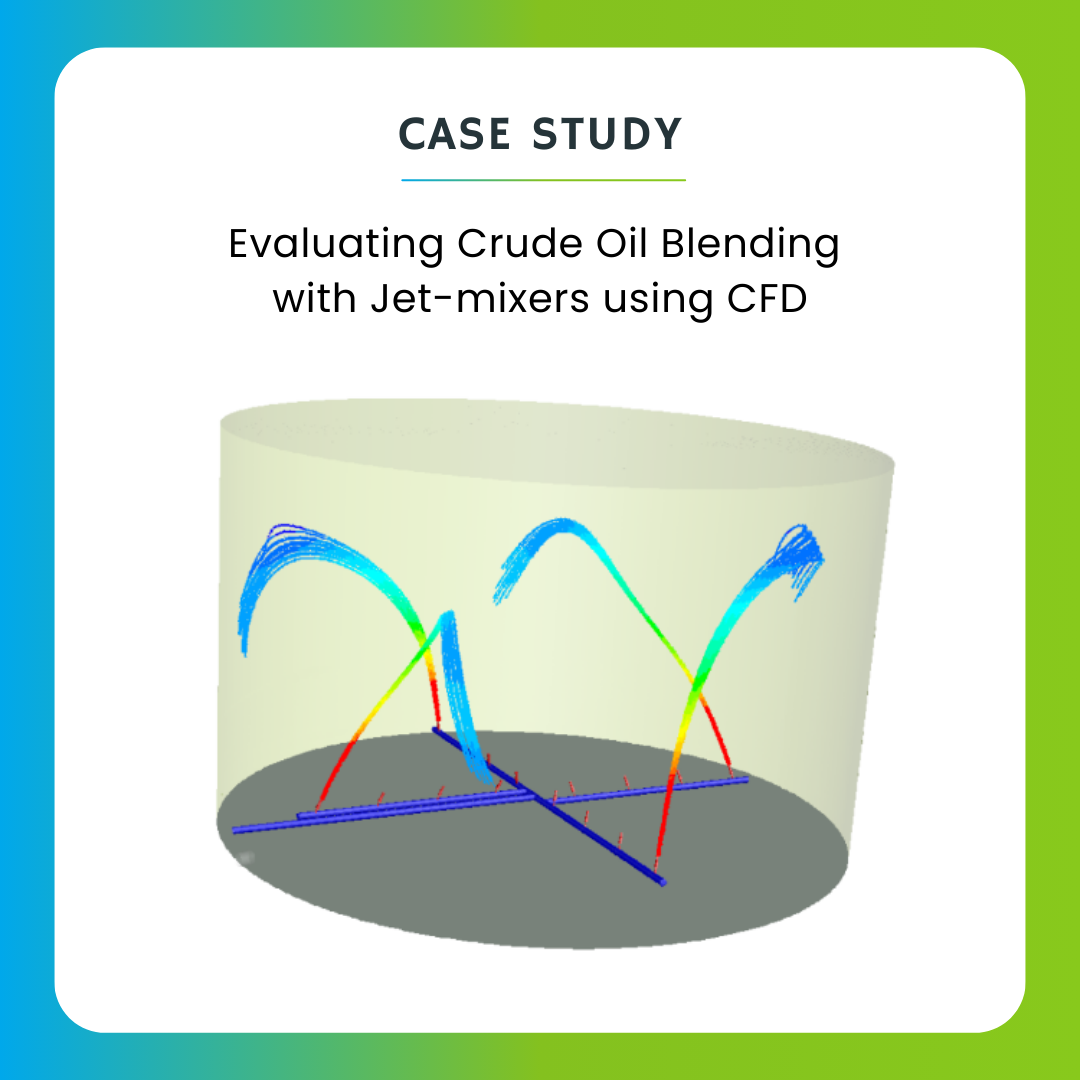

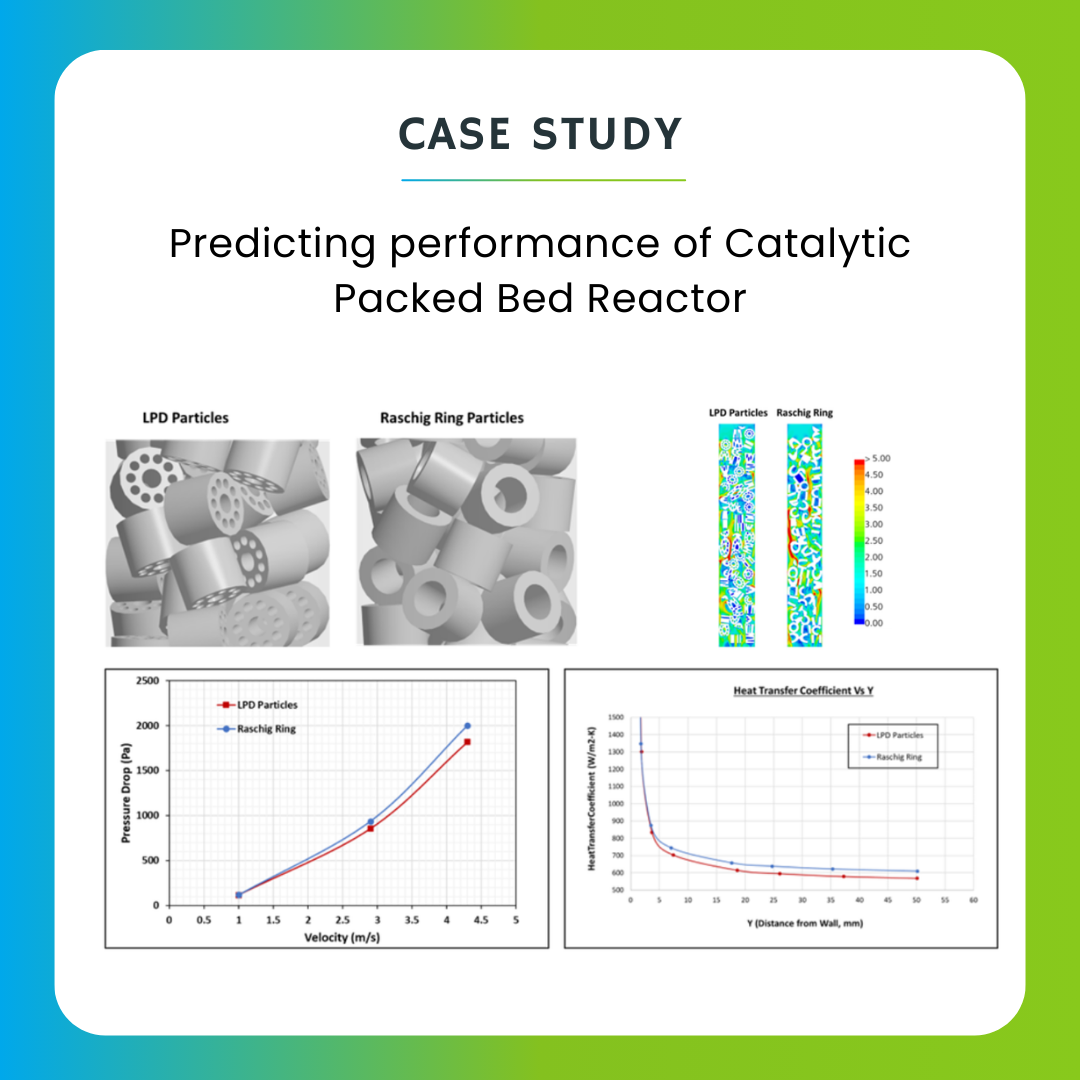

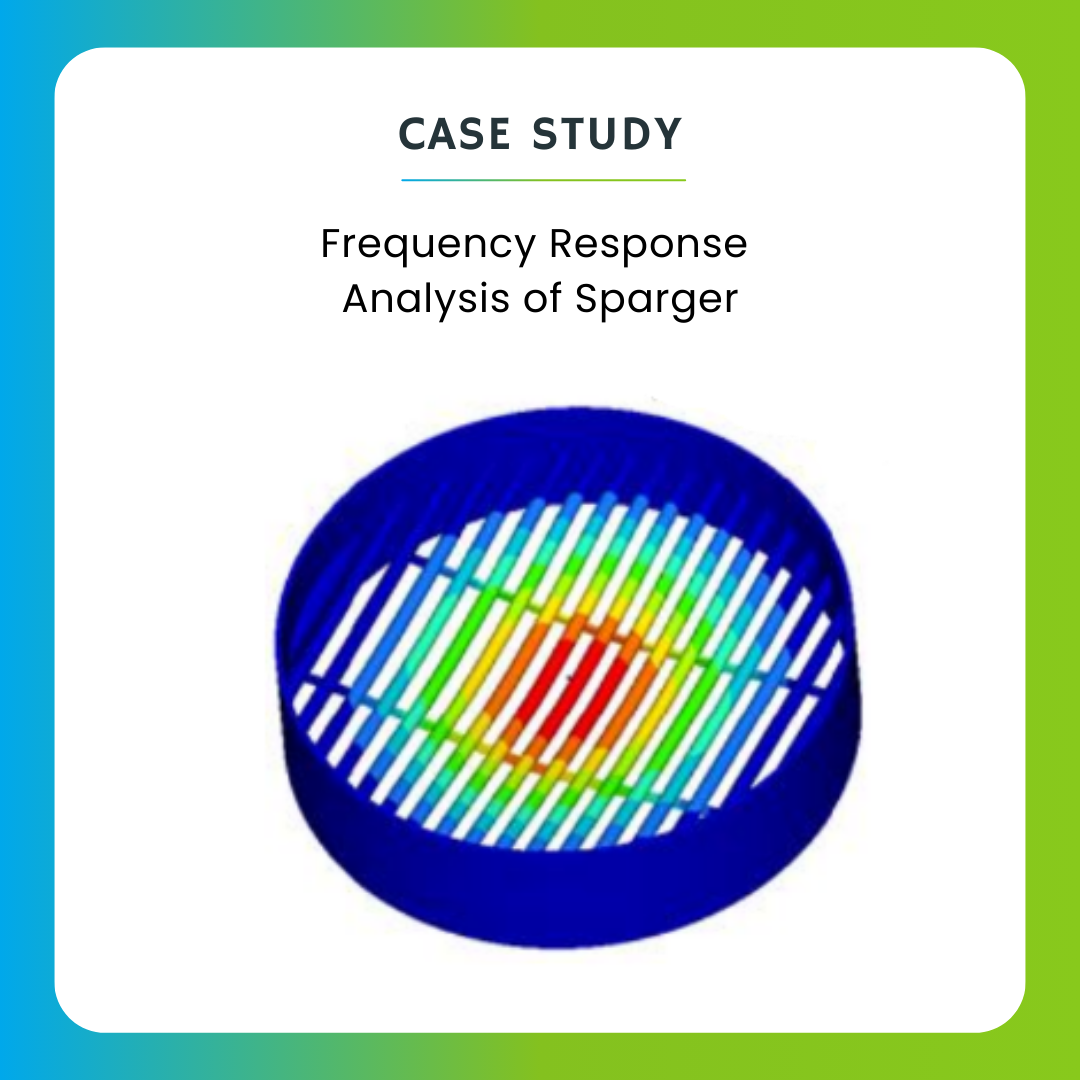

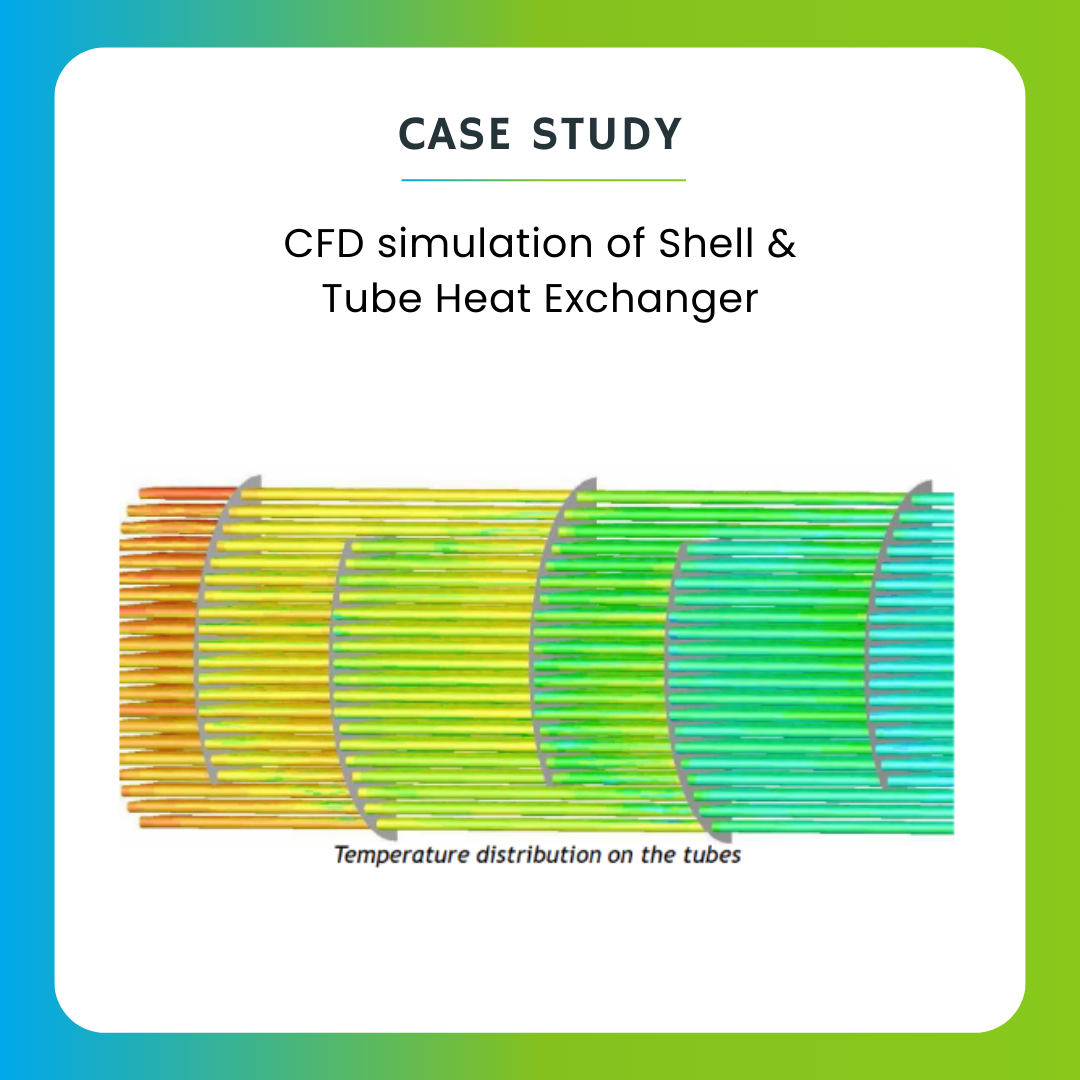

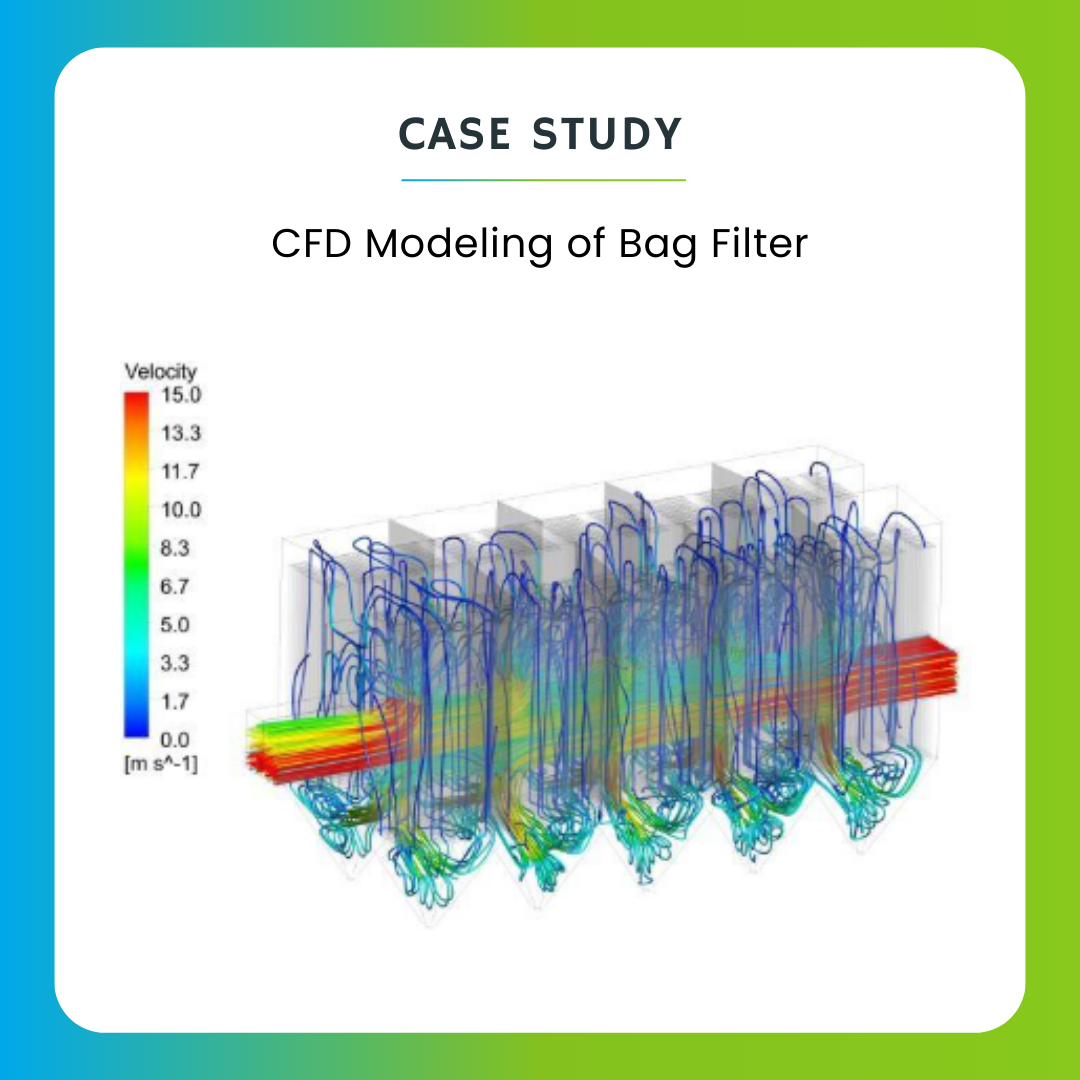

Despite of ever-evolving industries and complex value chains, digital engineering and experimental methods remain key to solving design, operational, and scale-up challenges. The following use cases highlight the application of Advanced Modeling & Simulation and Experimental Lab Scale-up in solving critical problems across diverse domains.

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.

.png)