Flow Assurance

About Practice

With a focus on proactive testing and innovative solutions, Tridiagonal Solutions is a trusted partner for smooth flow of operation from reservoir to processing facilities, minimizing downtime and maximizing production efficiency for of oil and gas. Our state-of-the-art facilities allow us to assess and mitigate issues such as wax deposition, asphaltene precipitation, transportation of sand, liquid metal, CO2 hydrate.

Wax Deposition Testing Facilities

Explore our cutting-edge facilities for wax research:

- Pipeline restart, large-scale experiments, and inhibitor impact in Wax Deposition Loop.

- Investigate wax removal, optimize stripping, and mitigate buildup in Wax Testing.

- Holistic exploration in one comprehensive facility.

Asphaltene Testing Facility

Enhance asphaltene management with our unique global testing facility. We offer:

- Large Pipeline: Assesses asphaltene dynamics in 1-inch or larger pipelines.

- High P&T: 40 barg pressure and 80°C temperature.

- Full Flow Coverage: Ranges from laminar to fully turbulent conditions.

- Custom Strategies: Creates tailored solutions from precise test results.

Sand Transportation Facility

.png?width=900&height=470&name=Sand%20Transport%20(1).png)

Our capability to mimic the on-field conditions allow us to execute sand transport study at various conditions. We offer:

- Study of well shutdown and well restart phase.

- Critical sand transport velocity in horizontal and inclined wells.

- Sand transport study in oil-water emulsion

Liquid Metal Transportation Facility

For mitigation of mercury accumulation from oil & gas pipeline in hilly terrain, our solution is

- Development of undulating pipeline rig with various inclinations.

- Entrainment of liquid metal at critical gas velocity.

- Visualization of multiphase flow phenomena using high-speed camera.

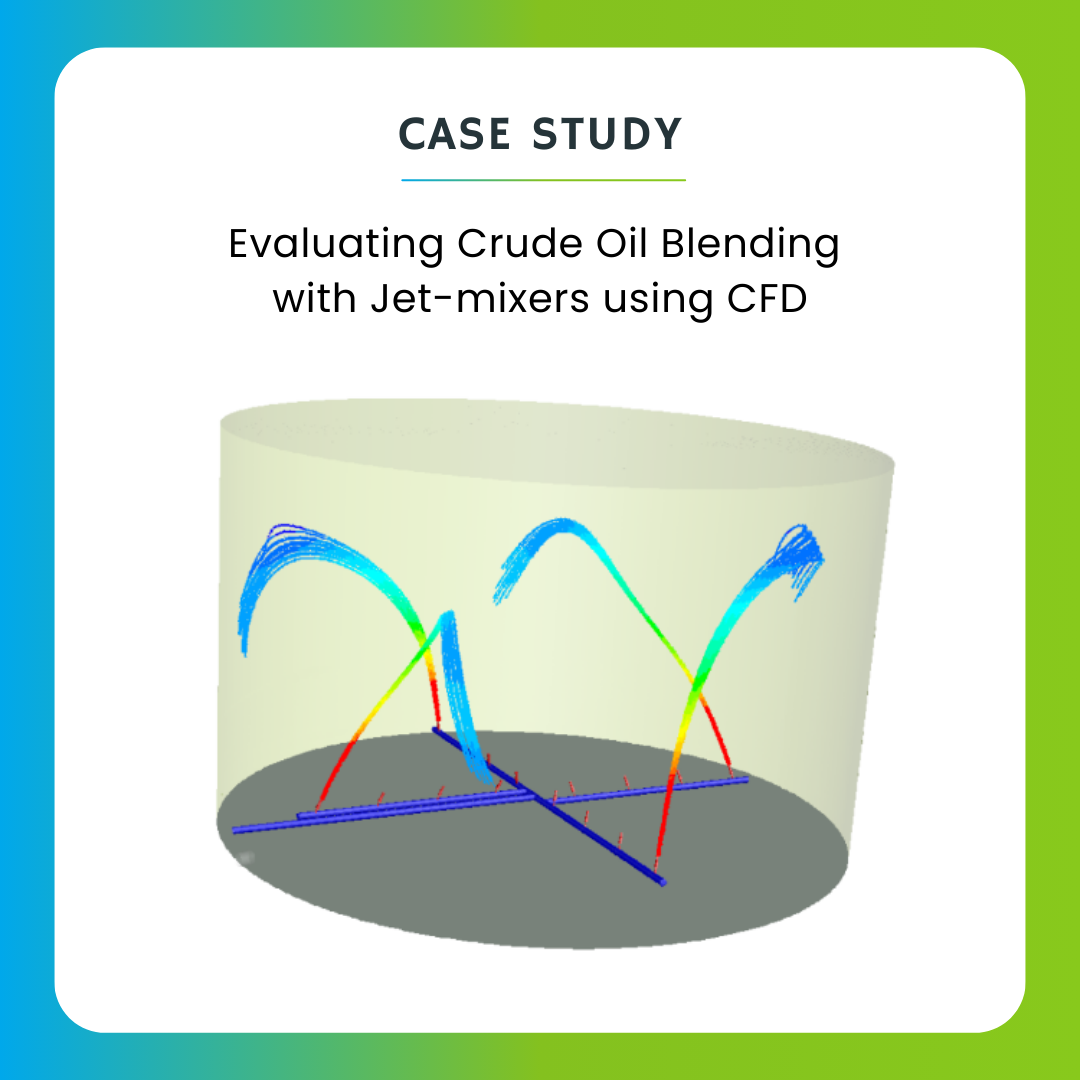

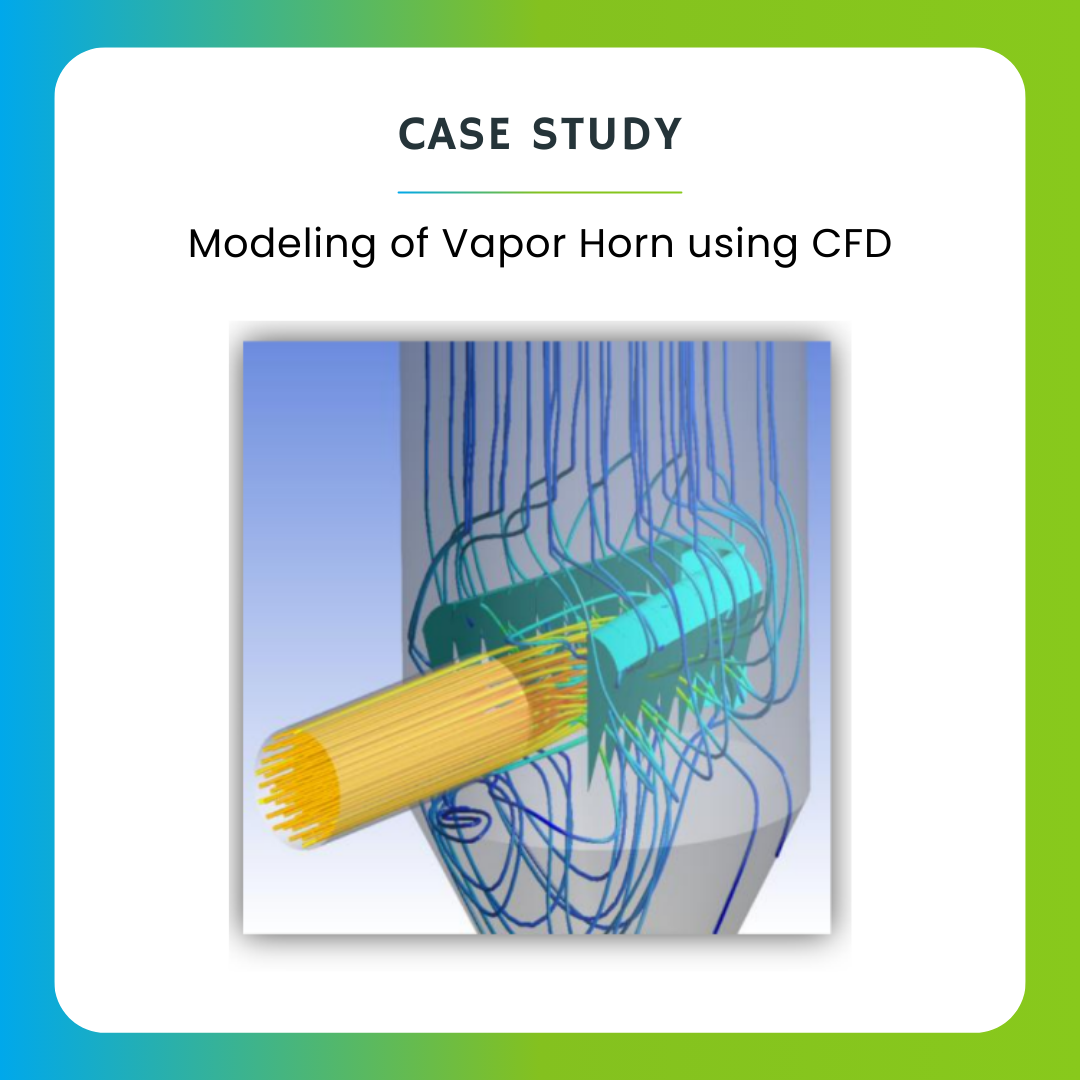

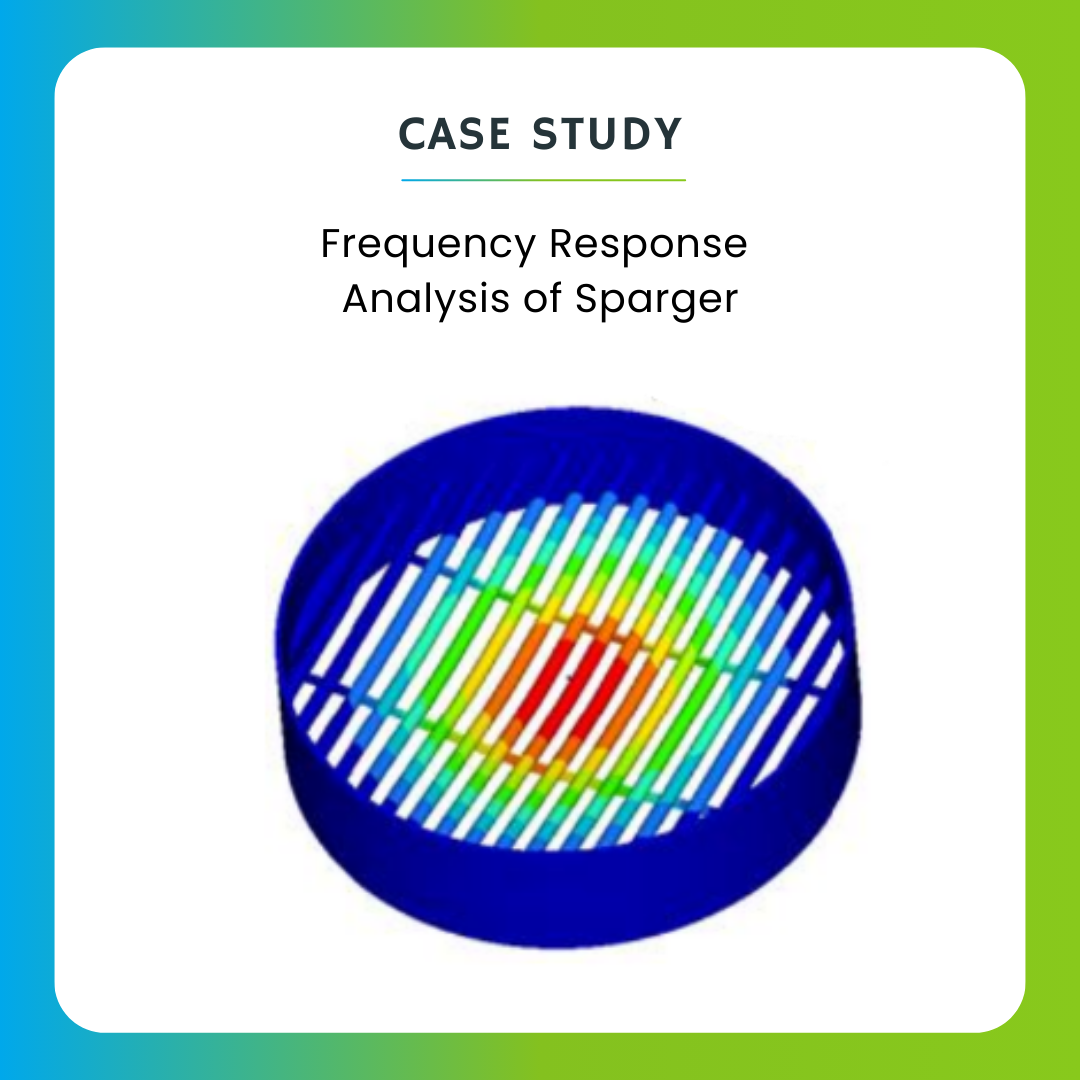

Use Cases

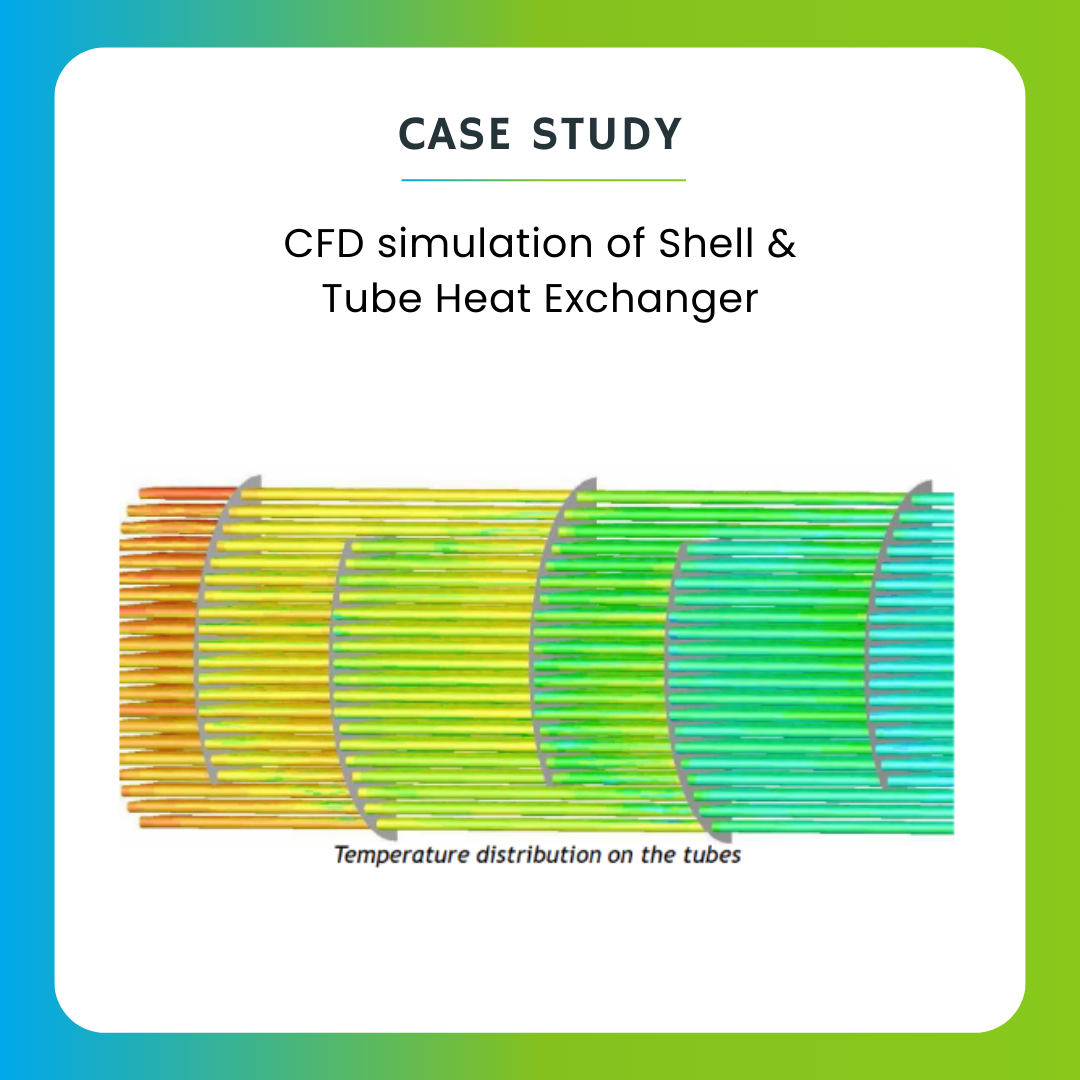

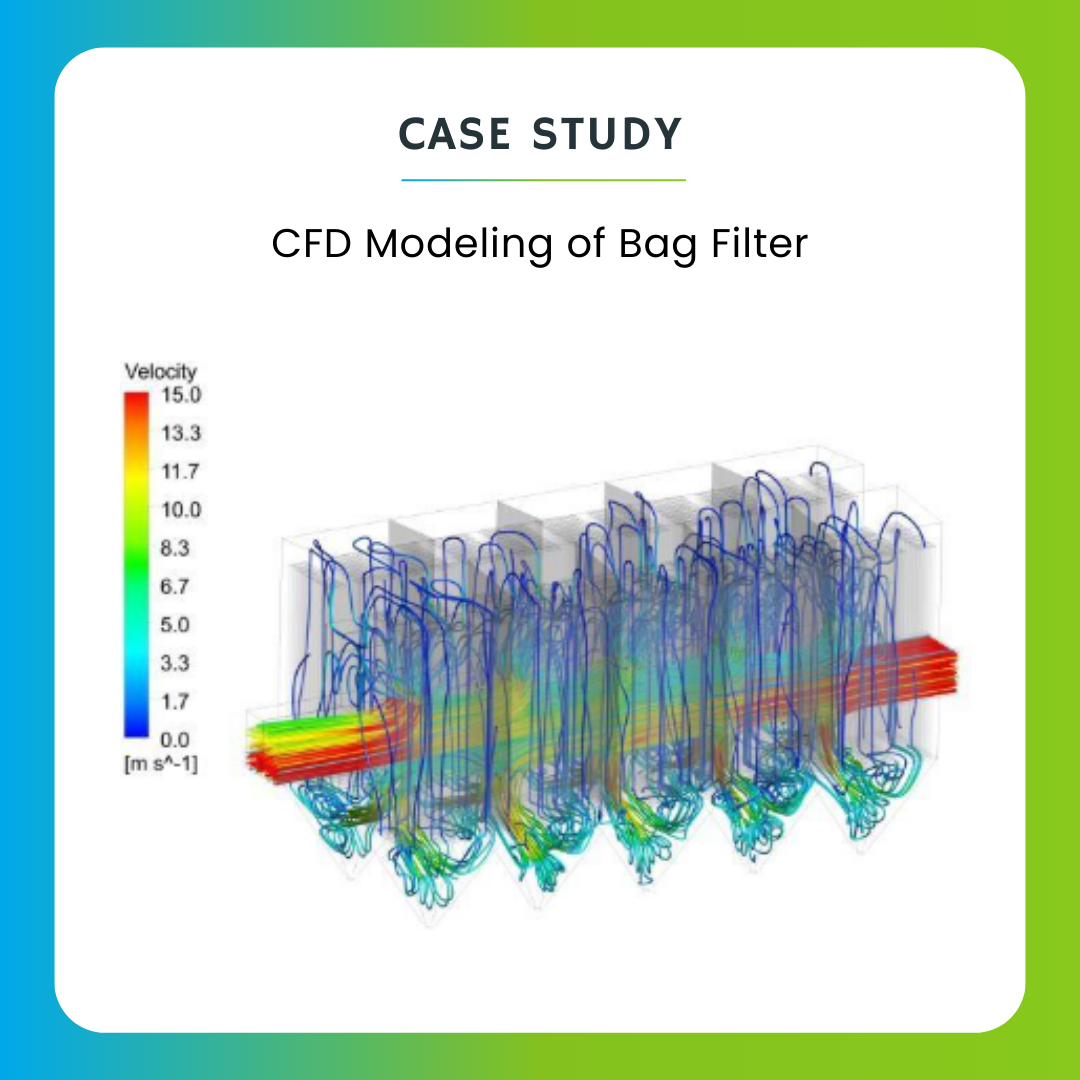

Despite of ever-evolving industries and complex value chains, digital engineering and experimental methods remain key to solving design, operational, and scale-up challenges. The following use cases highlight the application of Advanced Modeling & Simulation and Experimental Lab Scale-up in solving critical problems across diverse domains.

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.

.png)