Modernizing Maintenance Processes with Generative AI in the Manufacturing Industry with Look Out of Operations

Look Out of Operation is our Gen AI-powered solution that digitizes and optimizes maintenance workflows,integrating seamlessly with your existing systems like CMMS/ERP.

About Us

Tridiagonal Solutions Pvt. Ltd. (TSPL), Digital Transformation in Process Manufacturing is a premier Industry 4.0 consultant specializing in Manufacturing Excellence and Digital Transformation. We are an end-to-end execution partner for Chemical 4.0 programs, offering expertise in IT-OT integration, advanced data analytics, energy optimization, and Generative AI. Our capabilities span Digital Transformation Consulting, Process Data Analytics, Process Optimization, and more. From strategy to implementation and ongoing support, we ensure the success of your digital initiatives. Partner with us to unlock the full potential of your digital investments and drive transformative change in your operations.

How We Work?

How Generative AI Enhances Maintenance Processes with Look out of operation

-

Step 1Inspection Round

-

Step 2Maintenance Work Orders

-

Step 3Planning & Scheduling

-

Step 4Maintenance Execution

-

Step 5Maintenance Dashboard / Report

Inspection Rounds

BOOST EFFICIENCY AND SAFETY

Generative AI revolutionizes inspection rounds by automating scheduling, creating smart checklists, and ensuring accurate work orders.

- Smart Scheduling: AI optimizes inspection timing using historical data.

- Focused Checklists: AI targets high-risk areas, enhancing inspection effectiveness.

- Accurate Reporting: Automated reports improve compliance and reduce errors.

- Data-Driven Insights: AI logs and analyzes data, suggesting corrective actions.

Work Order Approval

Streamline Approvals and Improve Reliability

Generative AI simplifies the approval process by automating tasks, prioritizing work orders, and ensuring compliance.

- Task Prioritization: AI ranks work orders by urgency and impact.

- Compliance Checks: AI validates work orders against safety standards.

- Insightful Reports: AI delivers key insights to refine future processes.

Planning & Scheduling

Optimize Resources and Prevent Failures

Generative AI enhances planning by dynamically adjusting schedules and integrating safety compliance.

- Efficient Allocation: AI ensures optimal resource use.

- Safety Integration: AI embeds compliance into scheduling.

- Continuous Improvement: Real-time adaptability for smooth operations.

Maintenance Execution

Enhance Accuracy and Speed

Generative AI assists technicians with precise, step-by-step guidance for repairs.

- Tailored Instructions: AI customizes actions based on the situation.

- Safety Compliance: AI ensures adherence to SOPs and standards.

- Faster Repairs: AI speeds up tasks by recommending best practices.

Maintenance Dashboard / Report

BOOST EFFICIENCY AND SAFETY

Generative AI revolutionizes inspection rounds by automating scheduling, creating smart checklists, and ensuring accurate work orders.

- Smart Scheduling: AI optimizes inspection timing using historical data.

- Focused Checklists: AI targets high-risk areas, enhancing inspection effectiveness.

- Accurate Reporting: Automated reports improve compliance and reduce errors.

- Data-Driven Insights: AI logs and analyzes data, suggesting corrective actions.

Industries we are transforming with Gen-AI Based Look out of operation

Generative AI transforms maintenance into a seamless, efficient, and

reliable process, ensuring your operations run smoothly

Pharmaceuticals

.png?width=60&height=60&name=Automotive%20(2).png)

Manufacturing

Technology Behind the Transformation

POWERED BY AMAZON: SCALABLE, SECURE, AND INTELLIGENT

Our Gen AI-based maintenance solution is built on cutting-edge Amazon technology, ensuring a robust, secure, and scalable platform for your operations.

Product features

It has survived not only five centuries, but also the leap into electronic.

User-Friendly Interface

01Enables deep contextualization of maintenance data, providing comprehensive insights into equipment health, operational efficiency, and potential risks. This allows for informed decision-making and proactive maintenance strategies.

Maintenance Data Contextualization

01Enables deep contextualization of maintenance data, providing comprehensive insights into equipment health, operational efficiency, and potential risks. This allows for informed decision-making and proactive maintenance strategies.

Integrations

02Integrations with SAP, time series data, operating manuals, P&IDs, equipment design sheets, start up shut down SOP, etc.

Gen AI-Powered Maintenance Workflow Bot

03Leverages Generative AI to automate maintenance workflows, reducing manual intervention, minimizing errors, and ensuring consistency in maintenance procedures. This streamlines operations and enhances productivity across the plant.

Root Cause Analysis (RCA)

04Facilitates quick identification and resolution of underlying issues by performing in-depth root cause analysis. This capability helps reduce downtime, prevent recurring problems, and improve overall reliability.

Incident Reports

05Streamlines the documentation and management of incidents, ensuring that all issues are tracked, analyzed, and resolved efficiently. This leads to continuous improvement and better compliance with safety standards.

Historical Failure Analysis

06Utilizes historical data to predict potential failures and maintenance needs, allowing for proactive intervention before issues arise. This predictive capability minimizes unexpected downtime and extends equipment lifespan.

Cost Optimization and Prediction of Equipment Maintenance

07Provides accurate cost estimation and predictive analytics for equipment maintenance, helping to budget effectively and allocate resources efficiently. This ensures cost-effective maintenance planning and operations.

Analytics & Reporting

08Enables deep contextualization of maintenance data, providing comprehensive insights into equipment health, operational efficiency, and potential risks. This allows for informed decision-making and proactive maintenance strategies.

Refineries Maintenance KPIs With Gen-AI

Frequently Asked Questions

Find answers to frequently asked questions about our product features, capabilities, and how they can enhance your maintenance operations and equipment management.

What is Maintenance Data Contextualization?

Maintenance data contextualization provides insights into equipment health and operational efficiency by analyzing maintenance data. This enables better decision-making and proactive strategies.

How does the Gen AI-Powered Maintenance Workflow Bot improve productivity?

reproduced below for those interested. Sections 1.10.32 and 1.10.33 from "de Finibus Bonorum et Malorum" by Cicero are also reproduced in their exact original form, accompanied by English versions.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form.

How can Root Cause Analysis (RCA) benefit my maintenance process?

reproduced below for those interested. Sections 1.10.32 and 1.10.33 from "de Finibus Bonorum et Malorum" by Cicero are also reproduced in their exact original form, accompanied by English versions.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form.

What is the purpose of Historical Failure Analysis?

reproduced below for those interested. Sections 1.10.32 and 1.10.33 from "de Finibus Bonorum et Malorum" by Cicero are also reproduced in their exact original form, accompanied by English versions.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form.

How does cost optimization work in equipment maintenance?

reproduced below for those interested. Sections 1.10.32 and 1.10.33 from "de Finibus Bonorum et Malorum" by Cicero are also reproduced in their exact original form, accompanied by English versions.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form.

Life Science / Pharma

reproduced below for those interested. Sections 1.10.32 and 1.10.33 from "de Finibus Bonorum et Malorum" by Cicero are also reproduced in their exact original form, accompanied by English versions.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form.

Wait! Grab your Free Sales Consultation

Thank You

- List item : List Item Goes Here

- List item : List Item Goes Here

- List item : List Item Goes Here

Some more description can goes here

Wait! Grab your Free Sales Consultation

Thank You

- List item : List Item Goes Here

- List item : List Item Goes Here

- List item : List Item Goes Here

Some more description can goes here

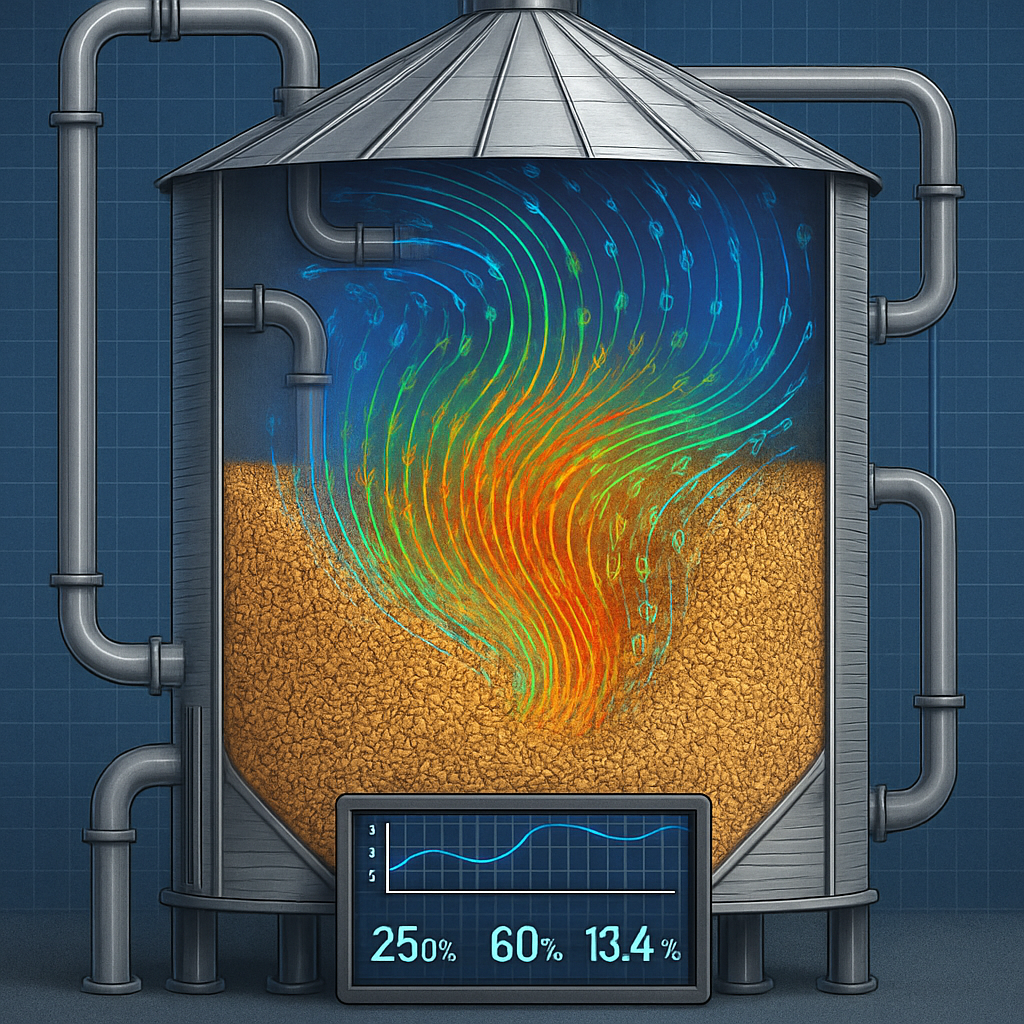

Use Cases

Get Started with Our Advanced Maintenance Solutions Today!

Discover how our features can revolutionize your maintenance processes and improve your operational efficiency. Take the first step towards a smarter, more proactive approach to equipment management.

.png)