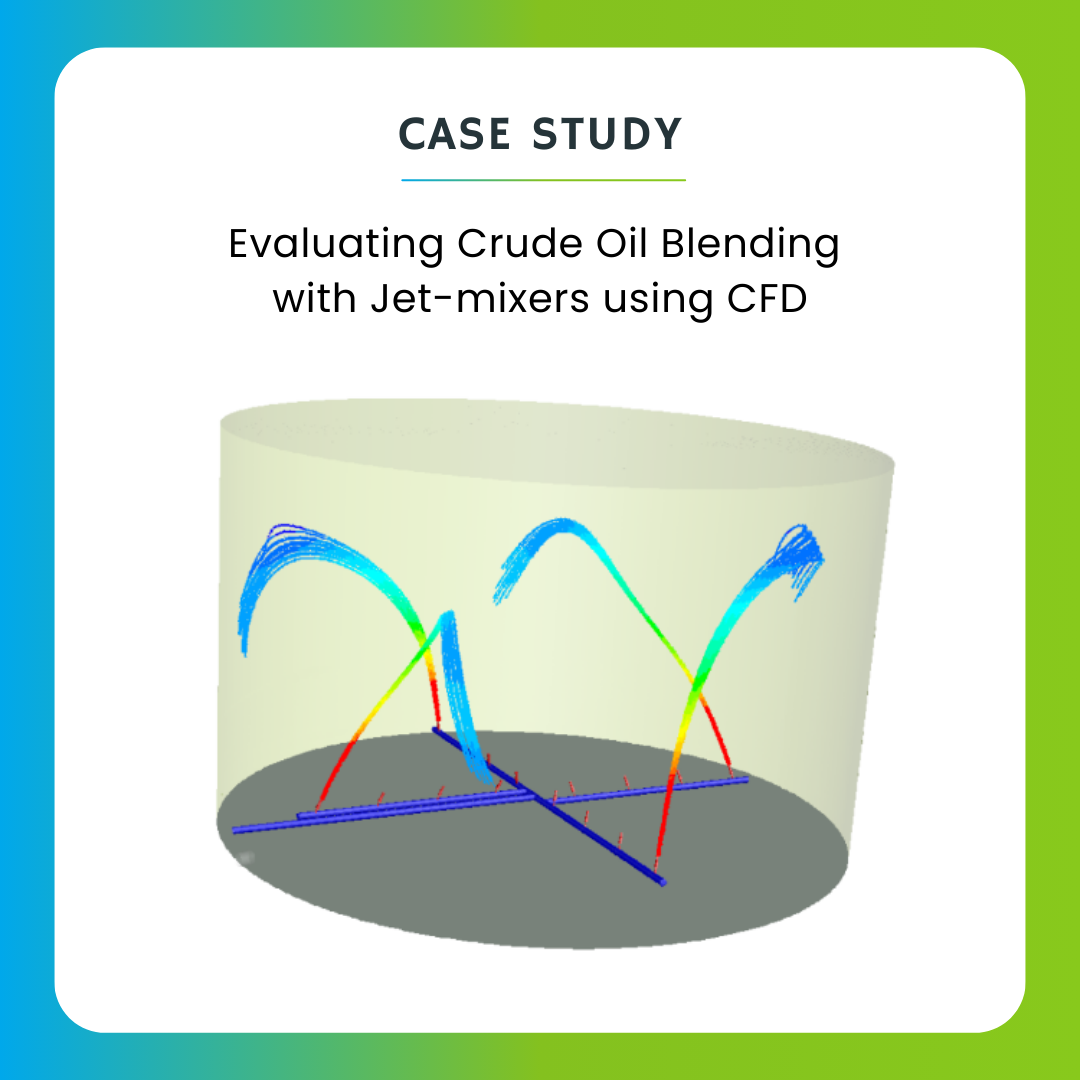

Evaluating Crude Oil Blending with Jet-Mixers using CFD

Crude oil blending is a critical refinery operation where improper mixer configuration can result in non-uniform blends and significant financial losses. This case study focuses on evaluating jet-mixer configurations inside blending tanks using Computational Fluid Dynamics.

.gif)

.png)

-1.png)

.png)