Stay Ahead of Change

Case Studies

Case Studies

Carbon Dioxide Capture, Utilization, and Sequestration

Published in ACS Engineering Au, this comprehensive Review by Srinu Nagireddi, Jatin R. Agarwal, and Damodaran Vedapuri*

Case Studies

Case Studies

Simulating Data Centers using CoolSim

Maintaining optimal inlet temperatures at server racks is critical for the reliable operation and longevity of data center equipment. These temperatures must remain within the limits recommended by ASHRAE standards to prevent overheating and performance degradation.

Case Studies

Case Studies

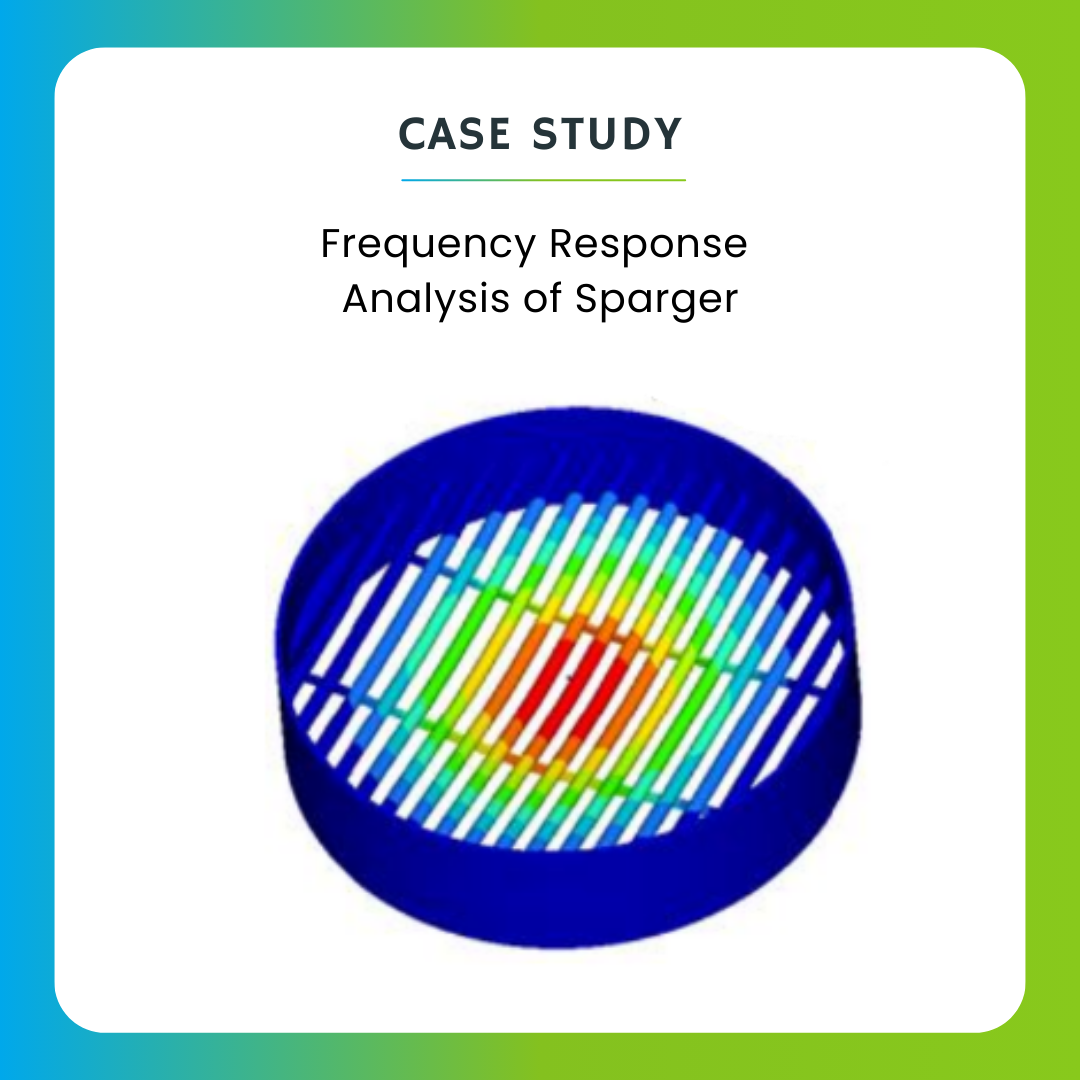

Frequency Response Analysis of Sparger

Gas mixing spargers are exposed to complex flow-induced forces due to high-velocity oxygen flow around horizontal tubes. These forces can generate vortex shedding, which may excite the structure at critical frequencies, leading to resonance, excessive deflection, and high stress levels.

Case Studies

Case Studies

Improving the Performance of Induced Gas Flotation Unit

The objective of this study was to improve the separation performance of the Induced Gas Flotation (IGF) unit by gaining deeper insights into internal flow behavior. CFD analysis was carried out to evaluate gas distribution patterns, identify inefficiencies affecting separation, and assess their impact on overall performance. Based on the simulation findings, design modifications were proposed to enhance gas–liquid interaction, improve separation efficiency, and optimize the overall effectiveness of the unit.

Case Studies

Case Studies

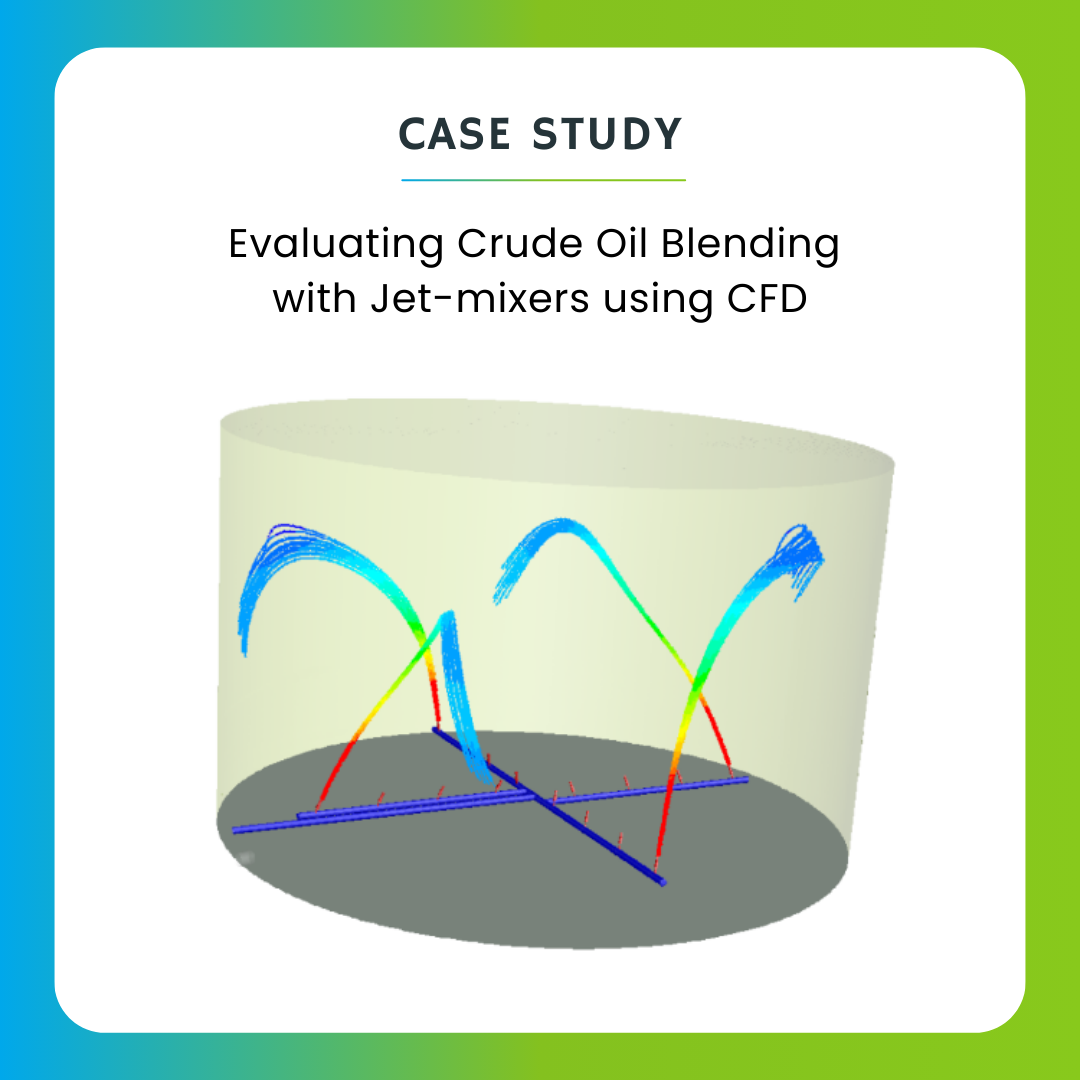

Evaluating Crude Oil Blending with Jet-Mixers using CFD

Crude oil blending is a critical refinery operation where improper mixer configuration can result in non-uniform blends and significant financial losses. This case study focuses on evaluating jet-mixer configurations inside blending tanks using Computational Fluid Dynamics.

Case Studies

Case Studies

CFD Models for Calculation of Dynamic Loads on Subsea Pipelines

Subsea pipelines are continuously subjected to complex hydrodynamic forces that impact their structural integrity over time. This case study focuses on developing CFD models to quantify static and dynamic external loads under different operating and environmental conditions.

Case Studies

Case Studies

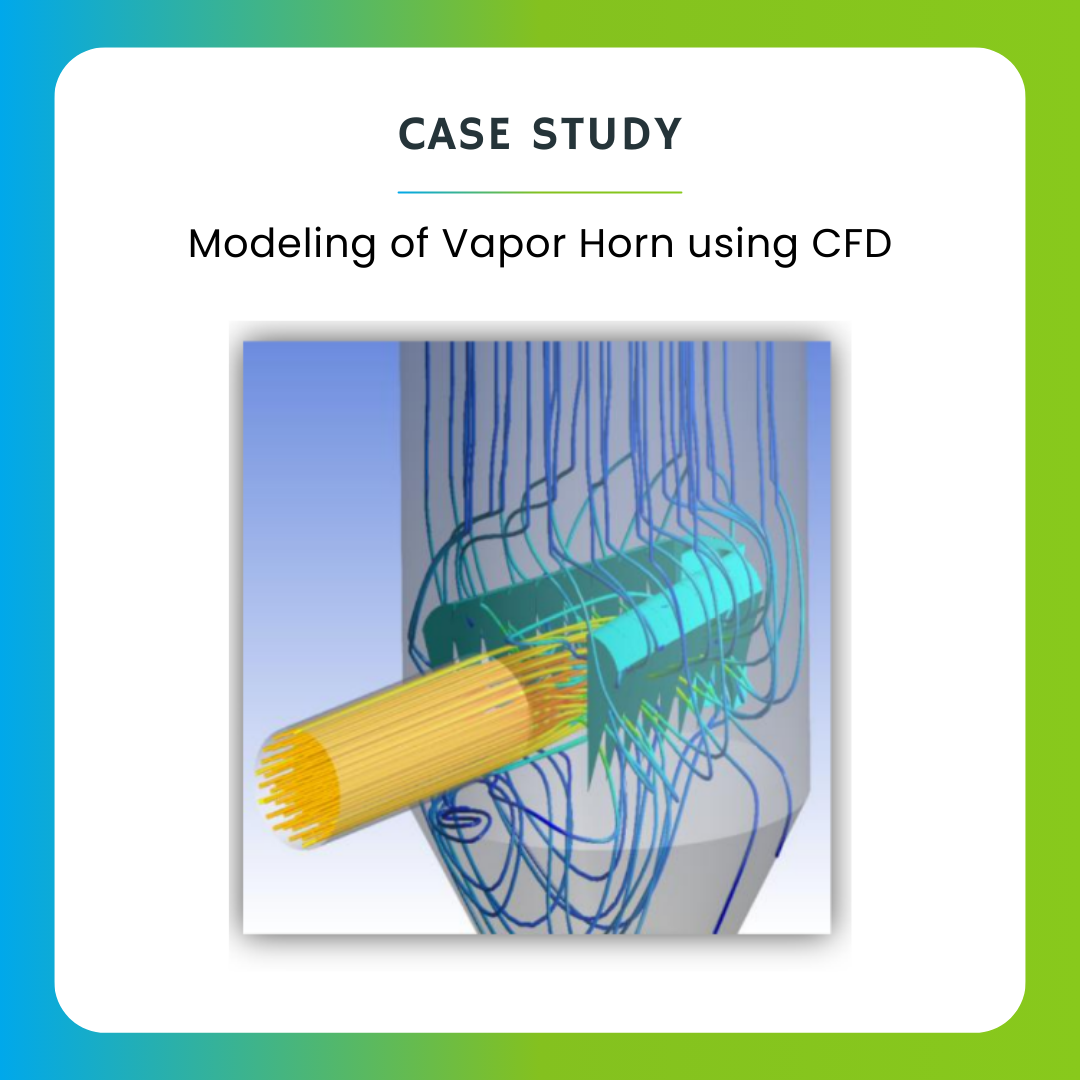

Modeling of Vapor Horn using CFD

Vapor horns play a crucial role in phase separation efficiency within process equipment. In this study, CFD modeling was carried out to analyze internal flow patterns and identify performance limitations affecting vapor separation efficiency.

Case Studies

Case Studies

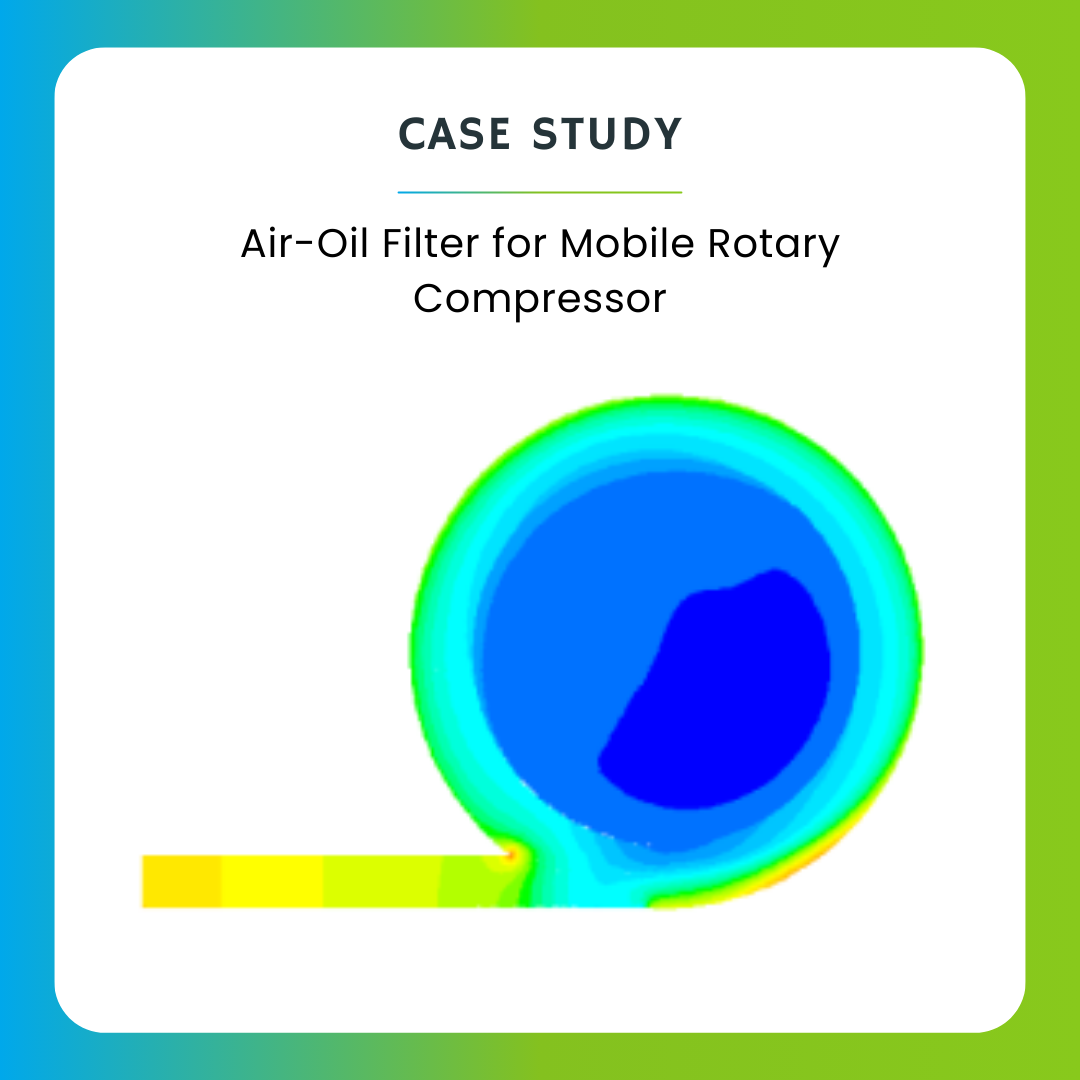

Designing & Developing Air-Oil Filter for Mobile Rotary Compressor

Efficient air-oil separation is critical for the performance and reliability of mobile rotary compressors. In this case study, advanced CFD simulations were used to analyze velocity distribution, pressure drop, flow behavior, and oil droplet dynamics inside the air-oil filter assembly. By closely studying internal flow profiles and oil separation mechanisms, the design was optimized to improve separation efficiency while maintaining acceptable pressure losses—ensuring enhanced compressor performance and longer service life.

Case Studies

Case Studies

CFD–FEA Coupled Simulation to Resolve Tube Failure in Oxygen Mixing Device

In complex process equipment, fluid-structure interaction can often lead to unexpected failures. Tridiagonal leveraged coupled CFD–FEA simulations to identify the root cause of repeated tube failures in an oxygen mixing device. The study revealed that fluid-induced vibrations from vortex shedding were exciting the natural frequency of sparger tubes, leading to structural resonance and eventual tube failure. While CFD accurately predicted the flow-induced vibration, FEA was used to estimate the mechanical natural frequencies of the tubes.

.gif) Case Studies

Case Studies

FEA to check Structural integrity of the Boiler Main Header and Stub Header

In high-temperature boiler systems, headers serve as vital components for collecting and distributing steam and water, while stub headers act as crucial connecting channels to other boiler elements. These tubular structures are regularly exposed to cyclic thermal loading during cold, warm, and hot startups — making them vulnerable to thermal fatigue over time. To maintain long-term operational safety and performance, it's essential to assess their structural integrity under realistic operating conditions.

Case Studies

Case Studies

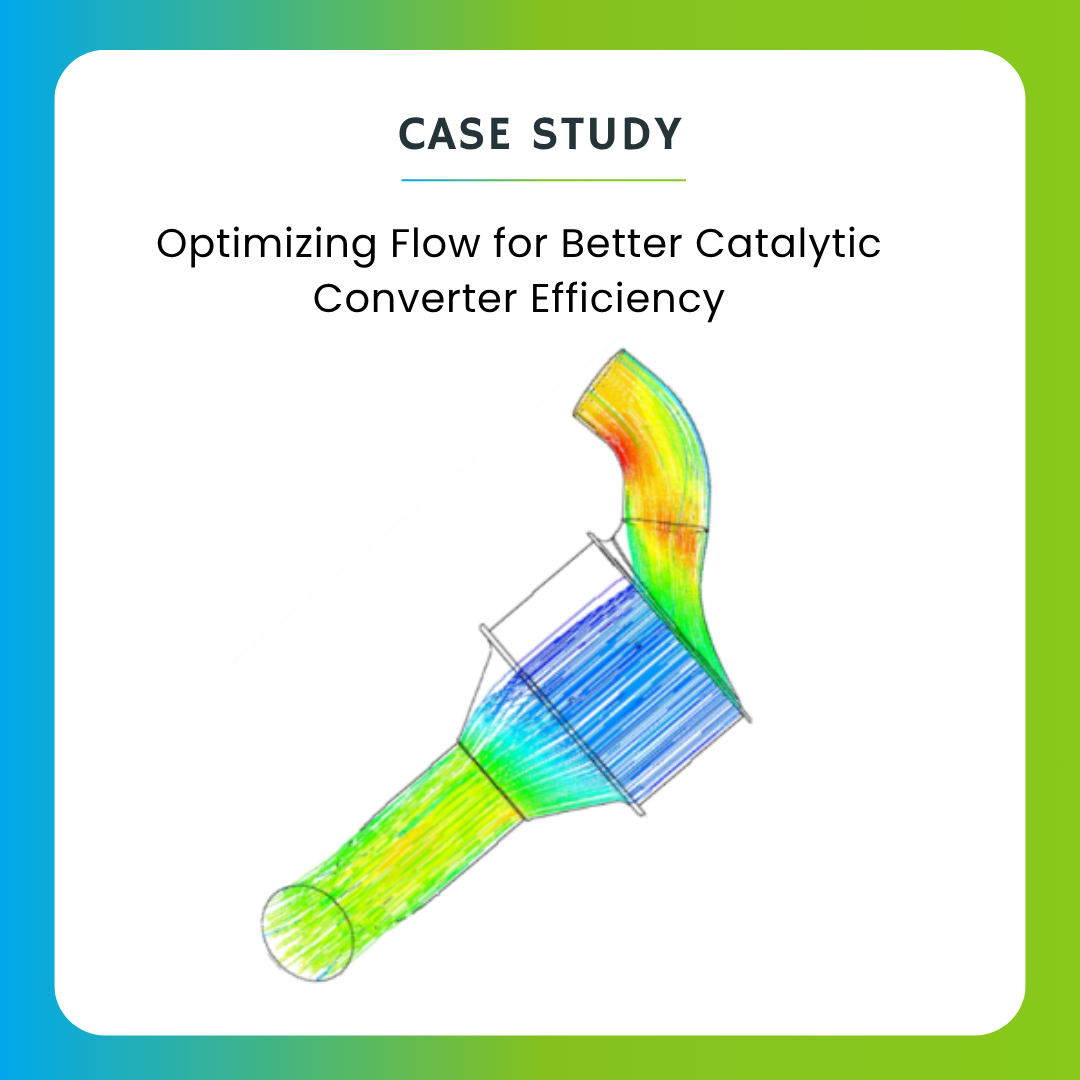

Flow Distribution in Catalytic Converter

Enhancing the efficiency and durability of catalytic converters and combustion systems is critical for optimal plant performance. This case study showcases how Computational Fluid Dynamics (CFD) was used to improve flow distribution in catalytic converters, leading to better pollutant conversion. It also highlights the role of detailed combustion modeling in minimizing thermal stresses and preventing tube failures—ultimately reducing shutdowns and improving operational reliability.

Case Studies

Case Studies

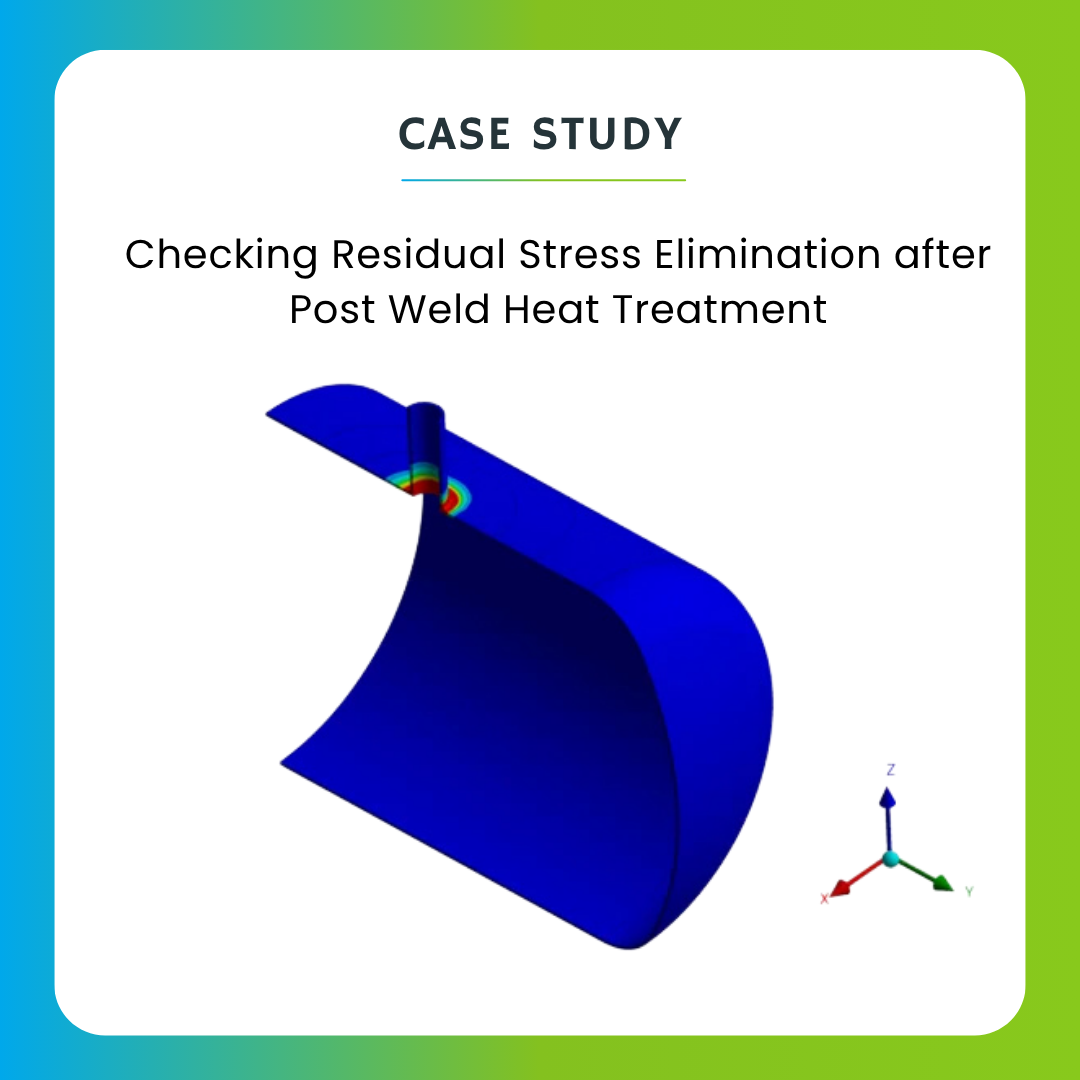

Checking Residual Stress Elimination after Post Weld Heat Treatment

Welding-induced residual stresses in pressure vessels pose significant risks—compromising structural integrity and leading to potential cracking under fluctuating pressure and thermal loads. This makes post-weld heat treatment (PWHT) a critical step in ensuring long-term durability. At Tridiagonal Solutions, our simulation experts developed a Finite Element Analysis (FEA) model that precisely captures the effects of heat treatment using a coupled transient thermal-structural approach. By focusing on critical weld junctions, we assess stress patterns in line with WRC Bulletin 452 and AWS D standards, helping to ensure design reliability and code compliance.

Brochure

Brochure

Erosion of Elbow and other pipe component Testing Facility

Industrial fluid systems, particularly those operating under high-velocity and abrasive conditions, place immense stress on essential components such as elbows, tees, reducers, and 3D pipe templates. Over time, this can result in significant erosion, jeopardizing equipment integrity, shortening component lifespan, and increasing operational risk. Tridiagonal Solutions offers a state-of-the-art Erosion Testing Facility designed to simulate realistic process conditions and evaluate the erosion performance of various stainless-steel grades, alloys, and component geometries. With this data, operators and manufacturers can proactively address weak points in design and material selection before costly failures occur.

Case Studies

Case Studies

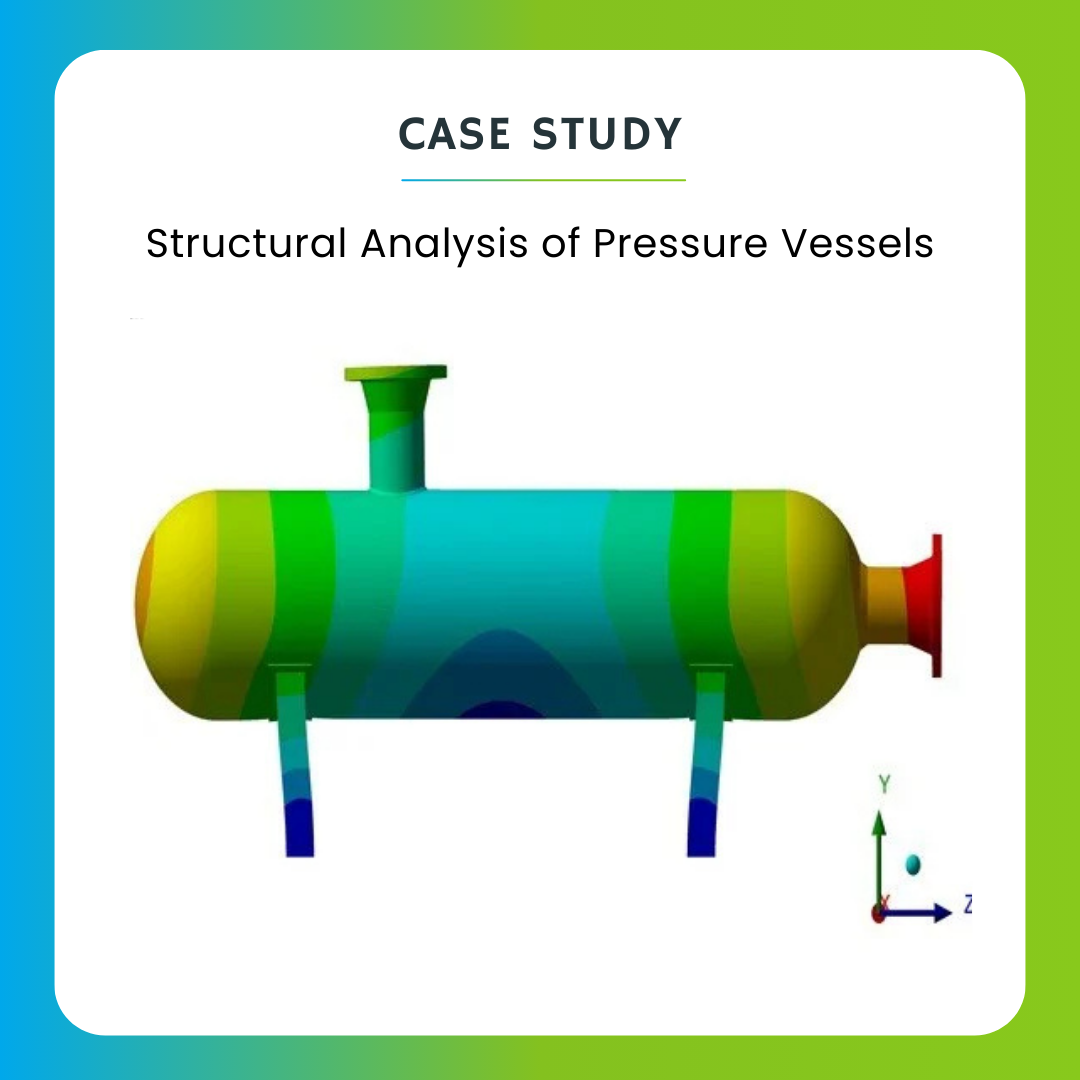

Structural Analysis of Pressure Vessels

This case study presents the structural analysis of pressure vessels to ensure safe and reliable operation under varying process conditions. Using advanced simulation techniques, the vessels were evaluated for stress distribution, deformation, and safety factors against operating loads and pressure fluctuations. The analysis helped in identifying critical stress regions, validating design integrity, and suggesting improvements for compliance with safety standards. See how structural simulation strengthened the reliability of pressure vessel design in this case study.

Case Studies

Case Studies

Liquid Entrainment and Jumper Study Flow Facility for Hydrate

This multipurpose test facility is utilized to conduct a number of multiphase flow studies ranging from hydrate transport to liquid entrainment. Hydrate mimic studies focus on understanding the impact of hydrate particles on flow regimes transitions and multiphase flow characteristics. Poly propylene particles are used as hydrate mimics. These particles float at the interface of oil and water. Liquid entrainment studies focus on determining the entrainment flux in low liquid loading systems. Starting from onset of entrainment when the first set of droplets are observed in the gas phase to close to a 97% entrainment, these studies focus on how gas velocities impact entrainment flux in both air-water and air-oil systems.

Brochure

Brochure

Asphaltene Deposition Facility

Asphaltene deposition remains one of the most persistent flow assurance issues in oil and gas production. These complex, heavy organic molecules can quickly accumulate, clogging flowlines, damaging equipment, and significantly reducing production efficiency. The challenge? No single mitigation strategy works across all reservoirs or crude types. Asphaltene behavior is highly dependent on the oil's composition, reservoir pressure and temperature, and even the effectiveness of chemical inhibitors varies widely. At Tridiagonal Solutions, we recognize the need for tailored solutions—not generalized fixes.

Case Studies

Case Studies

Paraffin Wax Stripping in Field-Scale Pipelines

Paraffin wax deposition in pipelines is a persistent challenge in crude oil transport, affecting flow efficiency and increasing maintenance costs. This case study explores the effectiveness of paraffin wax stripping under various operational conditions using a full-scale experimental pipeline setup.

Sand Control Screen Erosion and Flow Performance

Effective sand management is critical to ensuring the longevity and performance of oil and gas wells. Uncontrolled sand production can cause severe erosion in downhole equipment, leading to increased OPEX/CAPEX and reduced well productivity. This case study focuses on evaluating the erosion resistance and flow performance of sand control screens—key to retaining formation particles while enabling efficient fluid flow into production wells. Leveraging Tridiagonal’s advanced test loop setup, which includes a 2200 cfm gas compressor system (up to 7 bar pressure), and an in-house sand screw feeder (50–2000 g/hr dosing), comprehensive tests were conducted under realistic conditions. Additional capabilities like laser particle size distribution (PSD) analysis and Maximum Pore Passage (MPP) testing per API 19SS guidelines enabled precise performance evaluation. Download the full case study to explore how real-world testing and data-driven insights support the development of more robust, efficient sand control solutions for enhanced well performance.

.png) Case Studies

Case Studies

Multiphase & Single-Phase Flow Study for Sand Transport in Inclined Well

Understanding sand transport behavior in oil and gas wells is essential for designing effective sand management strategies. This case study presents a pilot-scale experimental loop designed to replicate wellbore conditions using tubular test sections with the same diameter as actual well designs, albeit at shorter lengths. The setup allows for both single-phase and multiphase flow studies to evaluate sand transport in inclined wells under realistic operating conditions.

-1.png) Case Studies

Case Studies

Liquid metal Transport

Mercury contamination in oil and gas pipelines poses serious challenges—leading to pipeline corrosion and environmental hazards due to biomagnification in marine ecosystems. This case study investigates the gas-assisted transport of liquid heavy metals, like mercury, to enable effective removal from pipelines.

.png) Case Studies

Case Studies

Erosion-Corrosion Testing

Erosion-corrosion experiments are pivotal for understanding the degradation processes in larger pipelines like 4-inch diameters, offering insights into the combined effects of both erosion and corrosion under real-world conditions. These insights are crucial for predicting and mitigating pipeline failures, guiding the development of robust materials and coatings, and optimizing maintenance strategies to ensure the safety, integrity, and longevity of larger pipelines.

Case Studies

Case Studies

Erosion Testing Setup

Tridiagonal Organization specializes in providing innovative solutions for various industries, including Oil & Gas, Pet Chemicals, Pharma, Food, Metals & Mining, Cement, etc. In these industries, equipment such as SS elbows, tees, reducers, and 3D templates are subjected to harsh operating conditions, including high velocities of abrasive fluids, which can lead to erosion. Erosion is a critical issue that can compromise the integrity and longevity of industrial components, resulting in costly repairs, downtime, and safety hazards. To address these challenges, Tridiagonal Organization has established a comprehensive erosion testing setup to assess the erosion resistance of its products and optimize their design and material selection.

Case Studies

Case Studies

Automated Inflow Control Device Erosion Testing Facility

Inflow Control Devices (ICDs) and Automated Inflow Control Devices (AICDs) are critical in enhancing well performance, balancing reservoir inflow, and minimizing unwanted fluid production. Tridiagonal Solutions offers a fully equipped testing facility designed to rigorously evaluate these devices under realistic wellbore conditions. Our testing portfolio includes cavitation testing, flow performance analysis, erosion resistance, and mud flow initiation and sediment plugging assessments—all in alignment with API 19ICD specifications. By simulating both single-phase and multiphase flows at pressures up to 200 bar, we deliver actionable insights to optimize device design and reliability in field deployment.