This multipurpose test facility is utilized to conduct a number of multiphase flow studies ranging from hydrate transport to liquid entrainment.

Hydrate mimic studies focus on understanding the impact of hydrate particles on flow regimes transitions and multiphase flow characteristics. Poly propylene particles are used as hydrate mimics. These particles float at the interface of oil and water.

Liquid entrainment studies focus on determining the entrainment flux in low liquid loading systems. Starting from onset of entrainment when the first set of droplets are observed in the gas phase to close to a 97% entrainment, these studies focus on how gas velocities impact entrainment flux in both air-water and air-oil systems.

Related Use Cases

-1.png?length=400&name=unnamed%20(4)-1.png)

Use Cases

Liquid metal Transport

.webp?length=400&name=Storage%20Tank%20(1).webp)

Use Cases

Liquid Flashing and Vibration in Storage Tank Feed Pipes

Use Cases

Development of Gas Void Fraction Sensor System

Publications

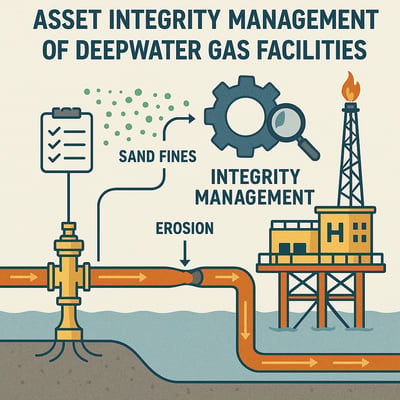

Sand Fines Erosion and Asset Integrity Management of Deepwater Gas Facilities...

Have a Question?

If you need assistance beyond what is provided above, please contact us.