Stay Ahead of Change

Case Studies

Case Studies

Industrial Ventilation

Ventilation plays a critical role in ensuring safe and efficient operation of industrial facilities. Properly designed ventilation systems help control airborne contaminants, maintain acceptable working conditions, and protect both personnel and equipment. This case study highlights how CFD simulations were used to address complex ventilation challenges and create a safer operational environment.

Case Studies

Case Studies

Simulating Data Centers using CoolSim

Maintaining optimal inlet temperatures at server racks is critical for the reliable operation and longevity of data center equipment. These temperatures must remain within the limits recommended by ASHRAE standards to prevent overheating and performance degradation.

Case Studies

Case Studies

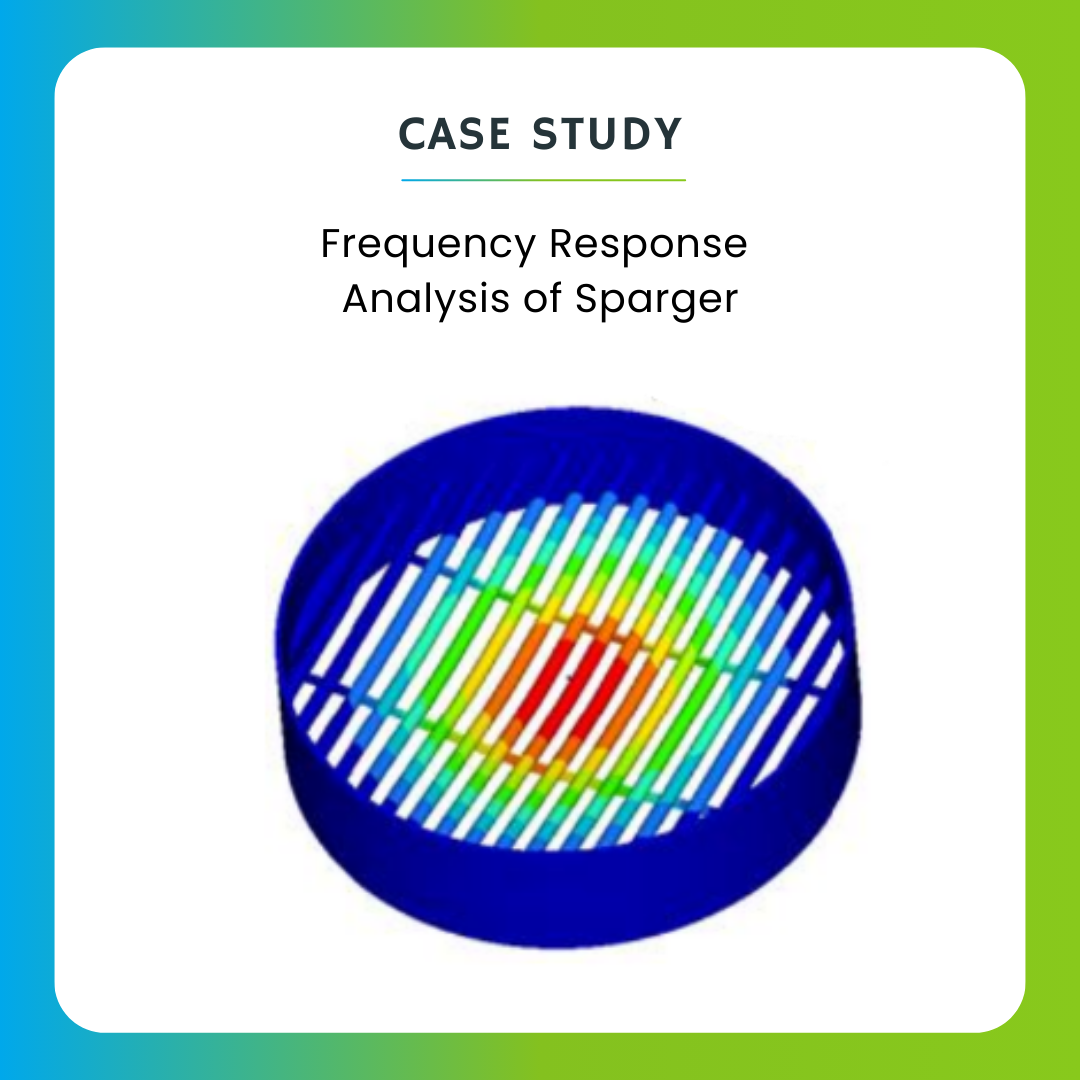

Frequency Response Analysis of Sparger

Gas mixing spargers are exposed to complex flow-induced forces due to high-velocity oxygen flow around horizontal tubes. These forces can generate vortex shedding, which may excite the structure at critical frequencies, leading to resonance, excessive deflection, and high stress levels.

Case Studies

Case Studies

Improving the Performance of Induced Gas Flotation Unit

The objective of this study was to improve the separation performance of the Induced Gas Flotation (IGF) unit by gaining deeper insights into internal flow behavior. CFD analysis was carried out to evaluate gas distribution patterns, identify inefficiencies affecting separation, and assess their impact on overall performance. Based on the simulation findings, design modifications were proposed to enhance gas–liquid interaction, improve separation efficiency, and optimize the overall effectiveness of the unit.

Case Studies

Case Studies

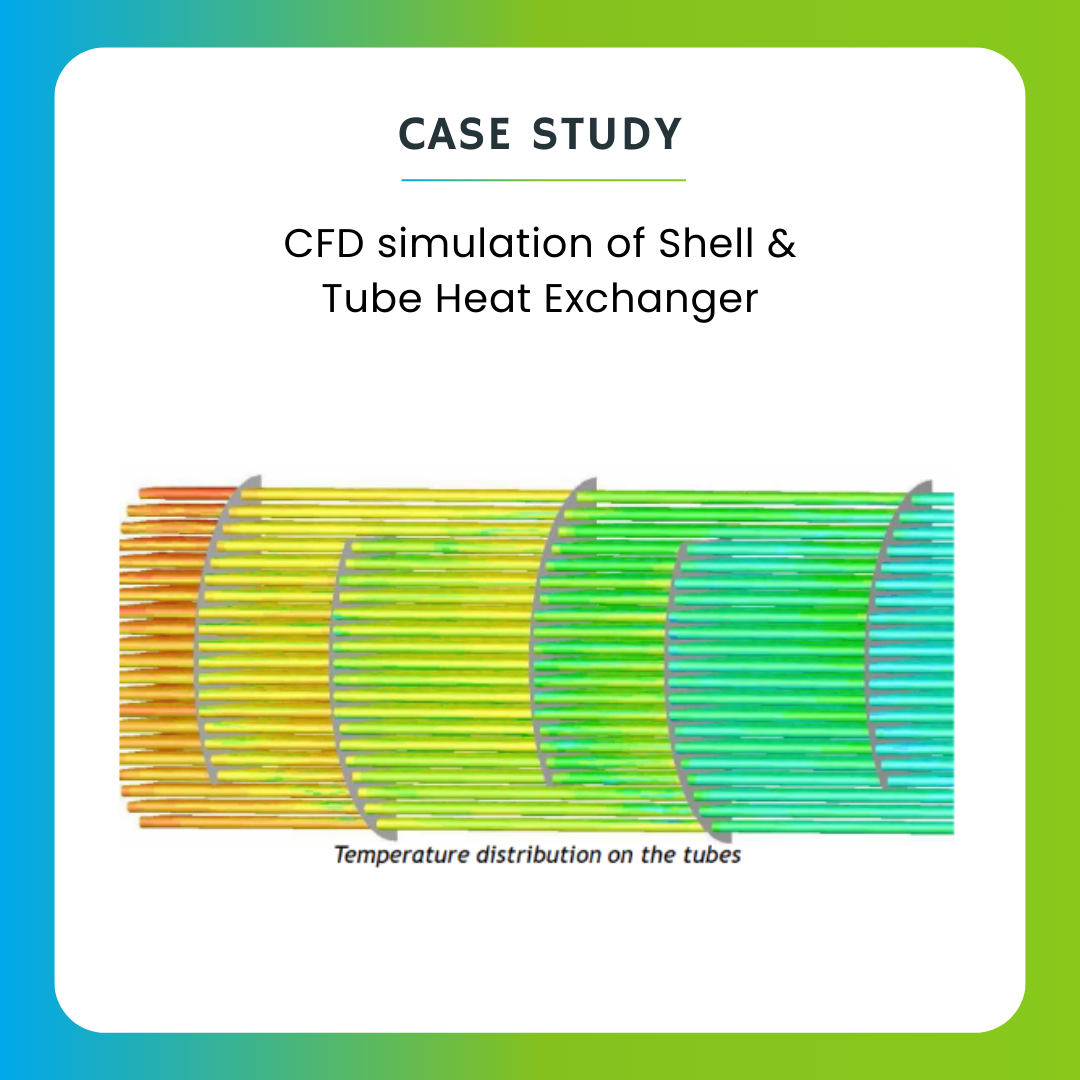

CFD Simulation of Shell & Tube Heat Exchanger

Start-up conditions in shell & tube heat exchangers involve strong thermal transients that directly influence temperature distribution, thermal stresses, and early-stage performance. In this study, the complete heat exchanger geometry was modeled using advanced CFD to accurately capture thermal mass effects and transient heat transfer behavior.

Case Studies

Case Studies

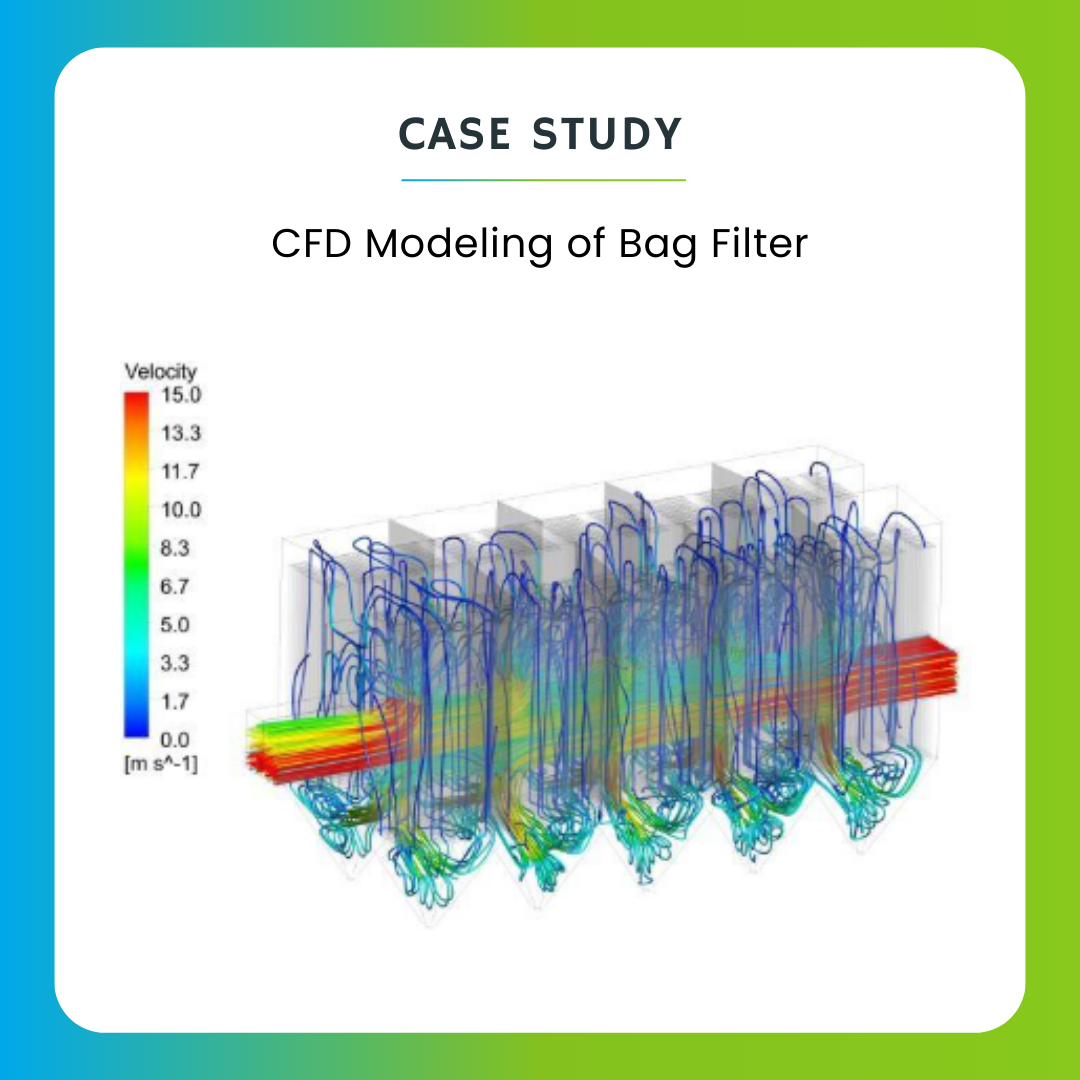

CFD Modeling of Bag Filter

In reverse-air baghouses, uneven gas flow can directly impact filtration efficiency, pressure drop, and bag life. This case study applies CFD to analyze internal flow behavior within a compartmentalized bag filter system under operating conditions.

.png) Case Studies

Case Studies

CFD Modeling of Electrostatic Precipitator

Electrostatic Precipitators demand highly uniform gas flow to meet particulate emission limits and achieve stable collection performance. In this study, CFD was used to evaluate flue gas flow distribution across the ESP cross-section and identify regions of velocity maldistribution impacting collection efficiency and dust re-entrainment.

Case Studies

Case Studies

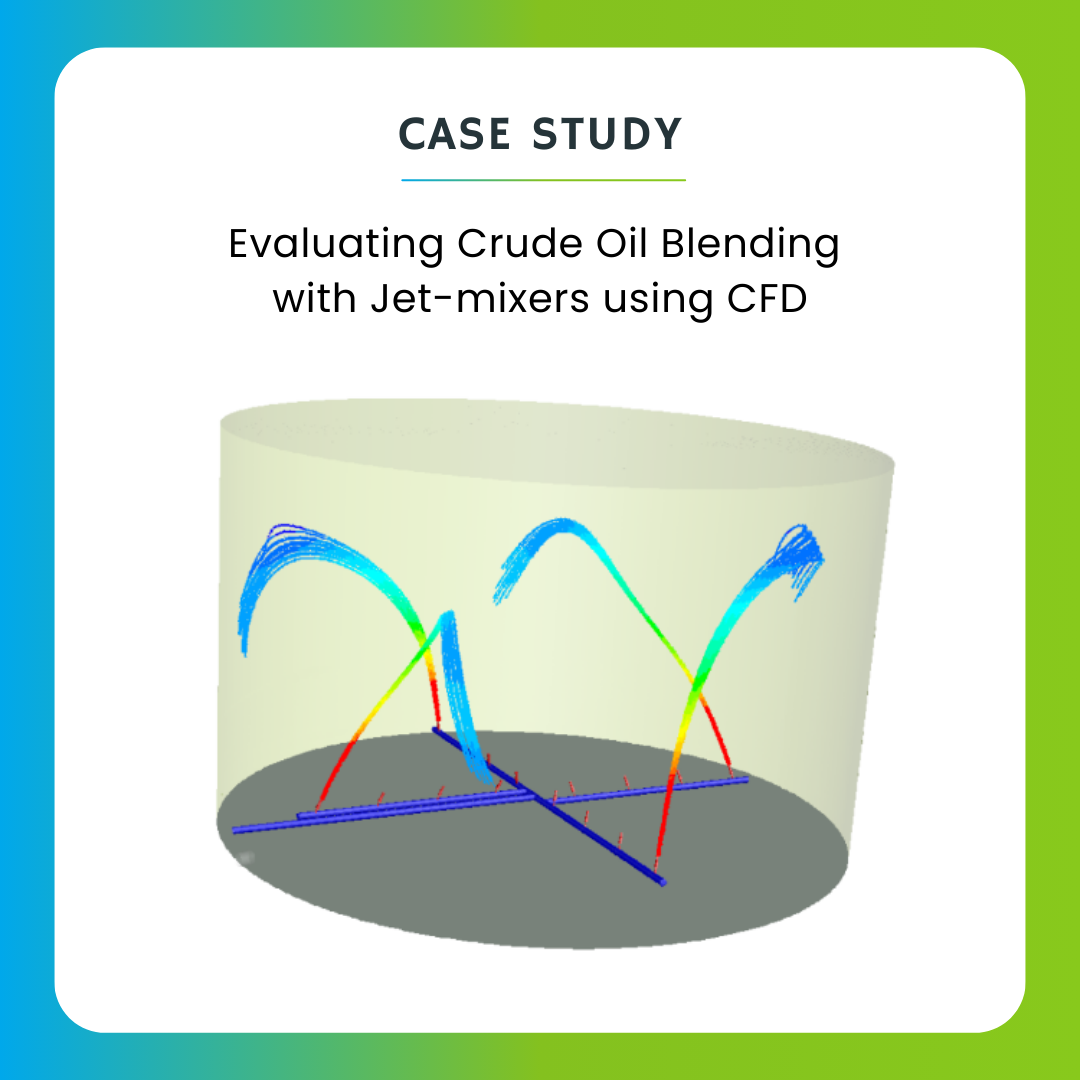

Evaluating Crude Oil Blending with Jet-Mixers using CFD

Crude oil blending is a critical refinery operation where improper mixer configuration can result in non-uniform blends and significant financial losses. This case study focuses on evaluating jet-mixer configurations inside blending tanks using Computational Fluid Dynamics.

Case Studies

Case Studies

CFD Models for Calculation of Dynamic Loads on Subsea Pipelines

Subsea pipelines are continuously subjected to complex hydrodynamic forces that impact their structural integrity over time. This case study focuses on developing CFD models to quantify static and dynamic external loads under different operating and environmental conditions.

Case Studies

Case Studies

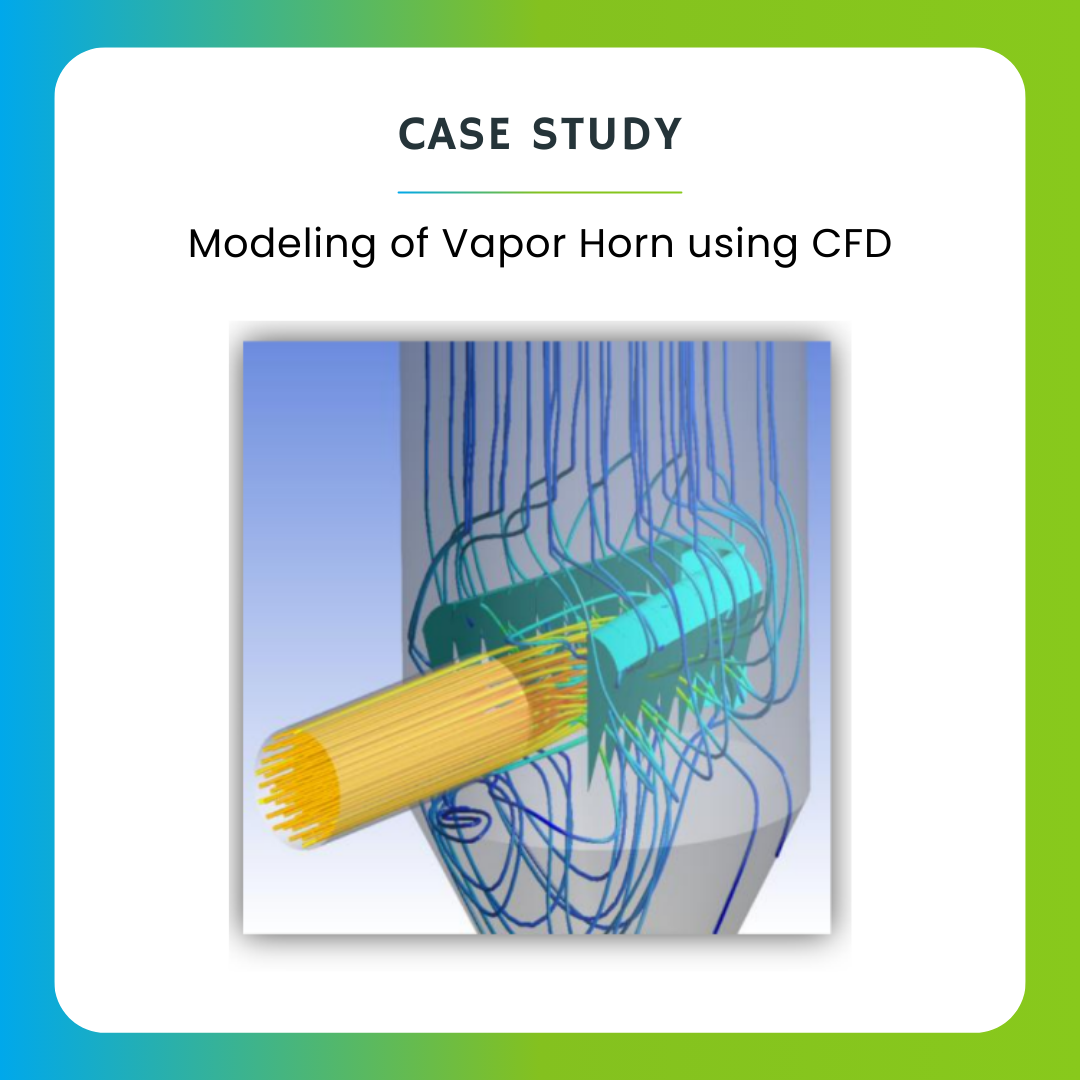

Modeling of Vapor Horn using CFD

Vapor horns play a crucial role in phase separation efficiency within process equipment. In this study, CFD modeling was carried out to analyze internal flow patterns and identify performance limitations affecting vapor separation efficiency.

Case Studies

Case Studies

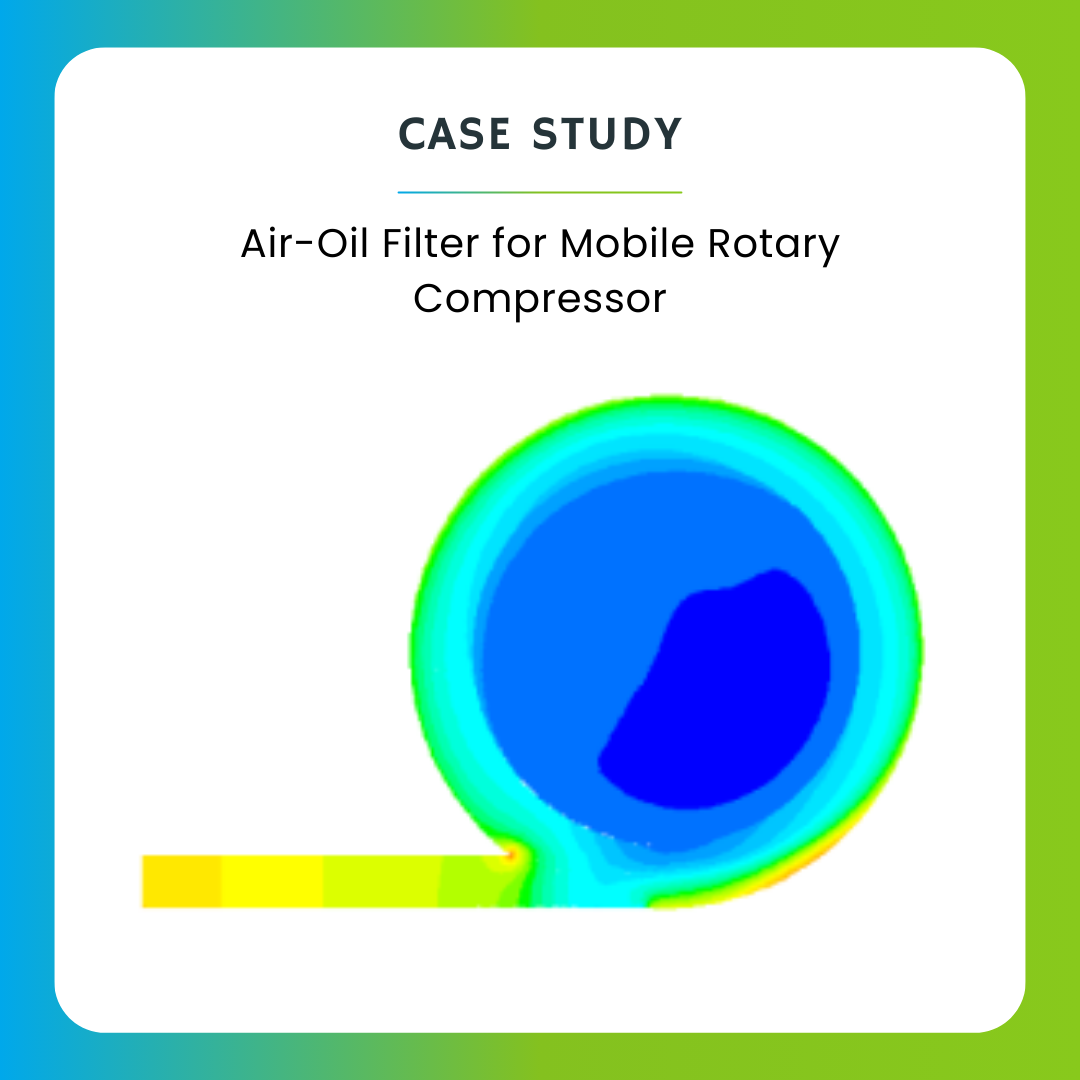

Designing & Developing Air-Oil Filter for Mobile Rotary Compressor

Efficient air-oil separation is critical for the performance and reliability of mobile rotary compressors. In this case study, advanced CFD simulations were used to analyze velocity distribution, pressure drop, flow behavior, and oil droplet dynamics inside the air-oil filter assembly. By closely studying internal flow profiles and oil separation mechanisms, the design was optimized to improve separation efficiency while maintaining acceptable pressure losses—ensuring enhanced compressor performance and longer service life.

Case Studies

Case Studies

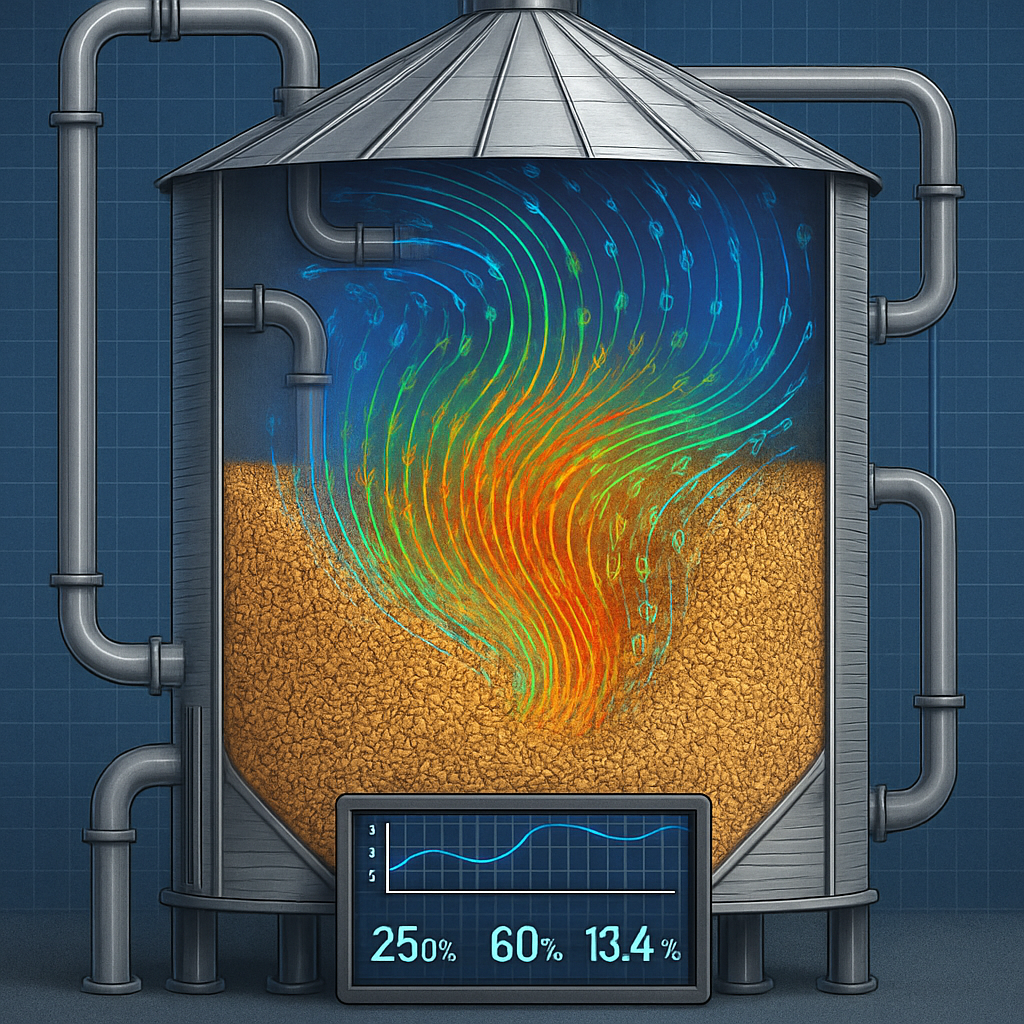

CFD Modeling for Drying of Grains in Silos

Efficient grain drying is critical to maintaining grain quality, shelf life, and storage safety in large-scale silo operations. In this case study, Computational Fluid Dynamics (CFD) is used to model the drying behavior of grains inside a silo, providing detailed insight into airflow distribution, heat and mass transfer, and moisture removal across the grain bed.

Case Studies

Case Studies

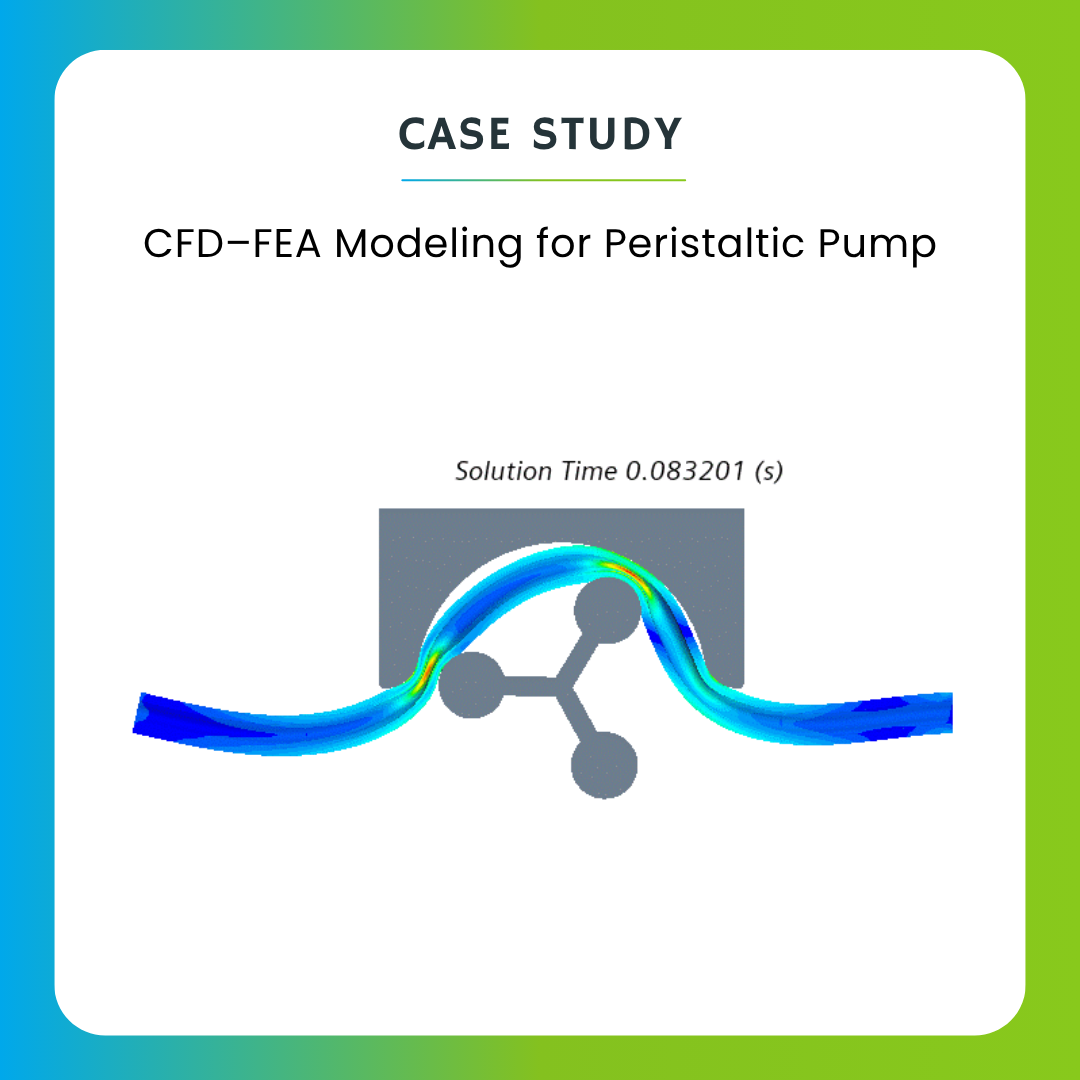

CFD-FEA Modeling for Peristaltic Pump

Understanding the interaction between rollers and tubing is critical for efficient peristaltic pump operation. At Tridiagonal Solutions, we leveraged non-linear structural (FEA) and CFD simulations to capture tubing deformation, pinch points, and fluid flow behavior.

Blogs

Blogs

Boosting Cement Industry Efficiency with Advanced CAE Simulations

Brochure

Brochure

Liquid Metal Transportation Facility

Heavy metals like mercury often migrate from natural sources—such as source rocks, metal-rich fluids, and oil-producing organisms—and accumulate within oil and gas pipelines, especially in complex terrains. This build-up poses serious challenges including corrosion, flow assurance risks, and environmental hazards. Our Liquid Metal Transportation Facility enables a deep dive into these issues through controlled, pilot-scale multiphase flow experiments that simulate real-world pipeline conditions. These tests focus on entraining and transporting heavy liquid metals like mercury within the gas phase to support pipeline cleaning and operational safety.

Brochure

Brochure

Sand Retention Testing

Effective sand control is critical for ensuring long-term well performance and minimizing damage to production equipment. Tridiagonal Solutions offers high-fidelity sand retention testing (SRT) to evaluate and select the most suitable sand screens tailored to your specific reservoir conditions. Our advanced SRT setup replicates formation-specific particle size distributions (PSDs), enabling accurate evaluation of screen efficiency in retaining sand at the formation face while allowing uninterrupted oil and gas flow. This ensures reduced risk of solids production, well failure, and costly remediation.

Brochure

Brochure

Sand Transportation Facility

Sand production from weak reservoirs is a persistent challenge in the oil and gas industry. When sand becomes entrained in crude oil, it often settles at the bottom of the pipeline, forming stationary beds that lead to serious operational issues—ranging from reduced production rates and excessive pressure drops to equipment failure, erosion, and corrosion. Our Sand Transportation Facility is purpose-built to help operators and researchers address these risks. Through rigorous testing, we analyze the movement of sand in multiphase flow systems and determine the minimum sand transportation velocity required to ensure continuous flow in horizontal and inclined pipelines.

Brochure

Brochure

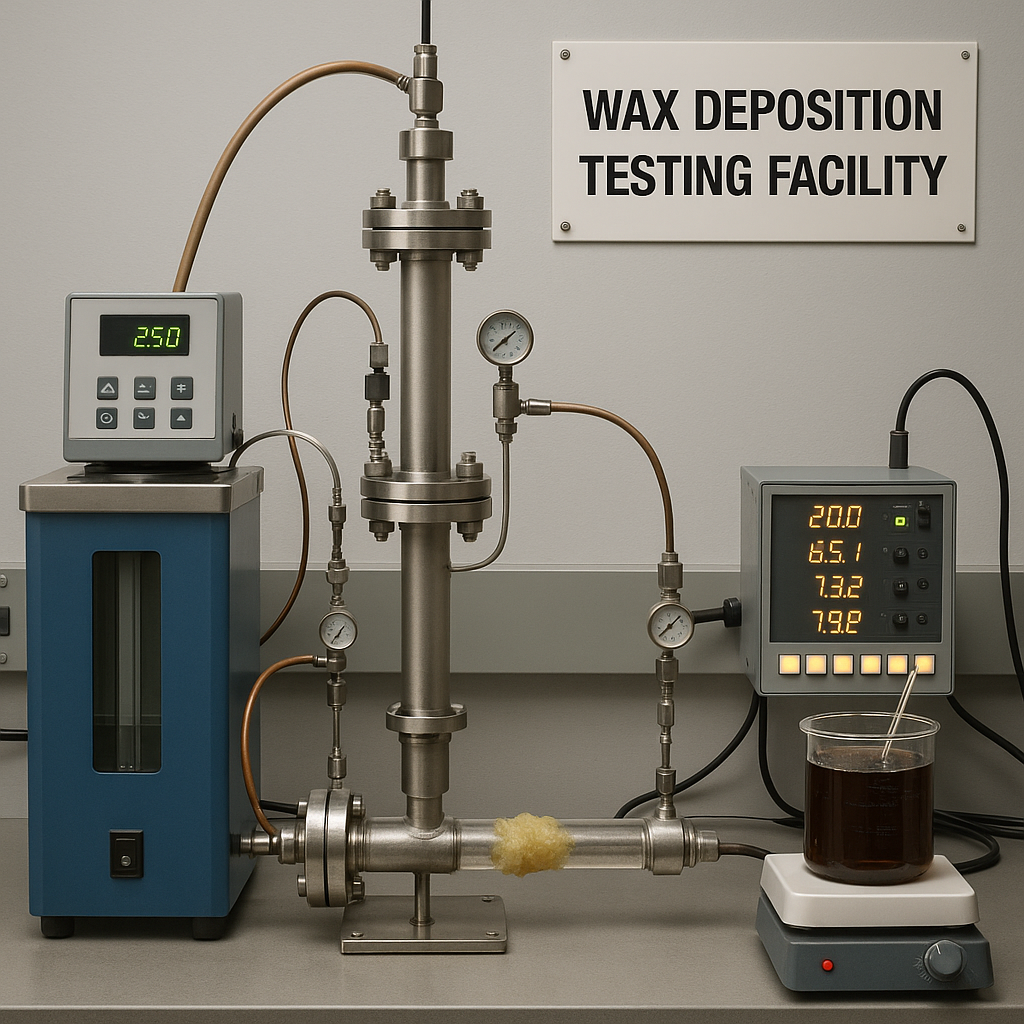

Wax Deposition Testing Facility

TSPL's wax deposition flow loop is a hub of innovation, driving transformative research in multiphase flow dynamics. With advanced instrumentation and visualization capabilities, it provides crucial insights into wax removal mechanisms. Pioneering initiatives conducted within the loop, like self-pigging technology and wax inhibition proofs, lead to substantial cost savings and enhanced operational efficiency for clients. This loop stands as a testament to TSPL's commitment to excellence and industry leadership.

Case Studies

Case Studies

CFD–FEA Coupled Simulation to Resolve Tube Failure in Oxygen Mixing Device

In complex process equipment, fluid-structure interaction can often lead to unexpected failures. Tridiagonal leveraged coupled CFD–FEA simulations to identify the root cause of repeated tube failures in an oxygen mixing device. The study revealed that fluid-induced vibrations from vortex shedding were exciting the natural frequency of sparger tubes, leading to structural resonance and eventual tube failure. While CFD accurately predicted the flow-induced vibration, FEA was used to estimate the mechanical natural frequencies of the tubes.

Blogs

Blogs

Sand Blast for Erosion Testing in Coated Coupons: Strengthening Material Durability

Blogs

Blogs

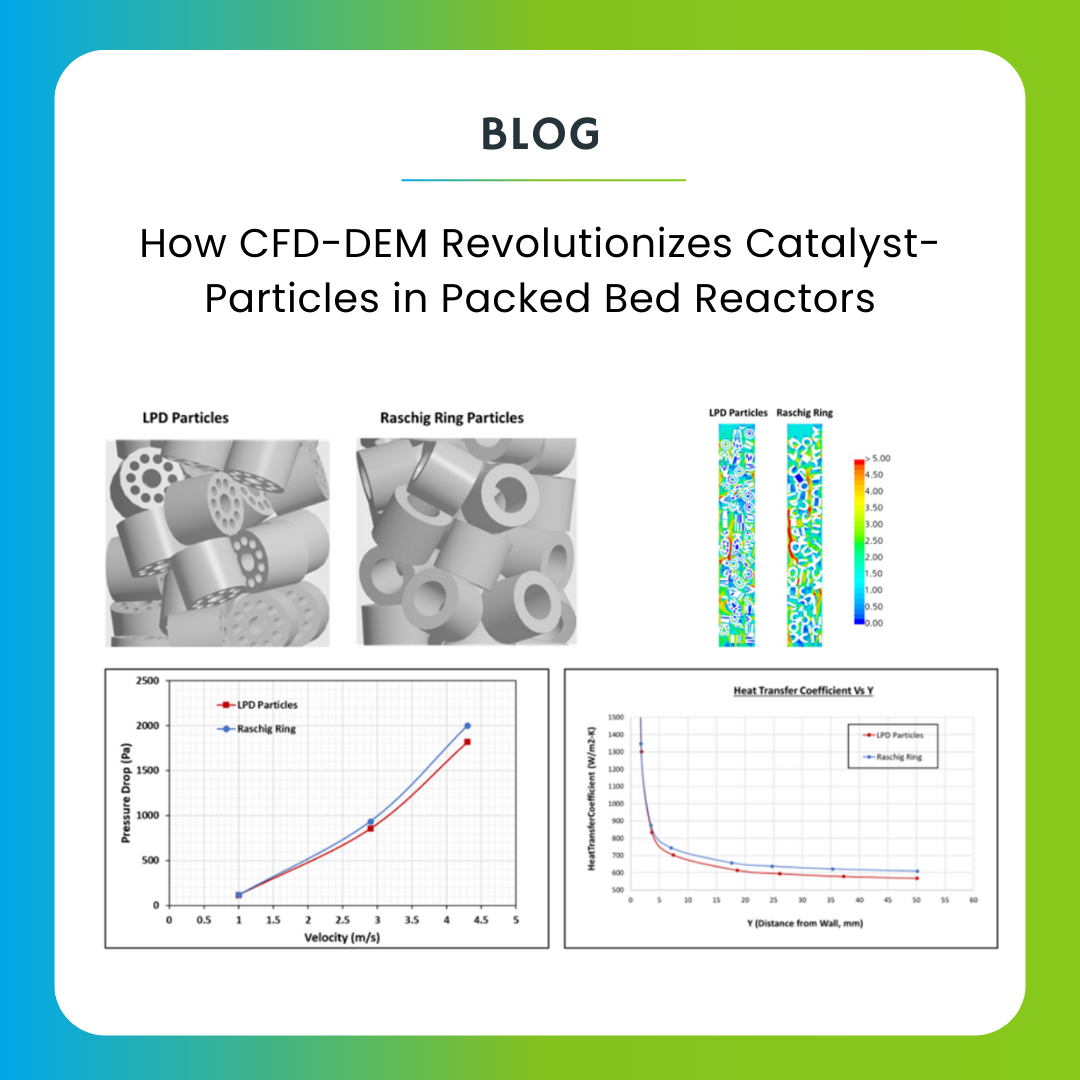

How CFD-DEM Revolutionizes Catalyst-Particles in Packed Bed Reactors

Case Studies

Case Studies

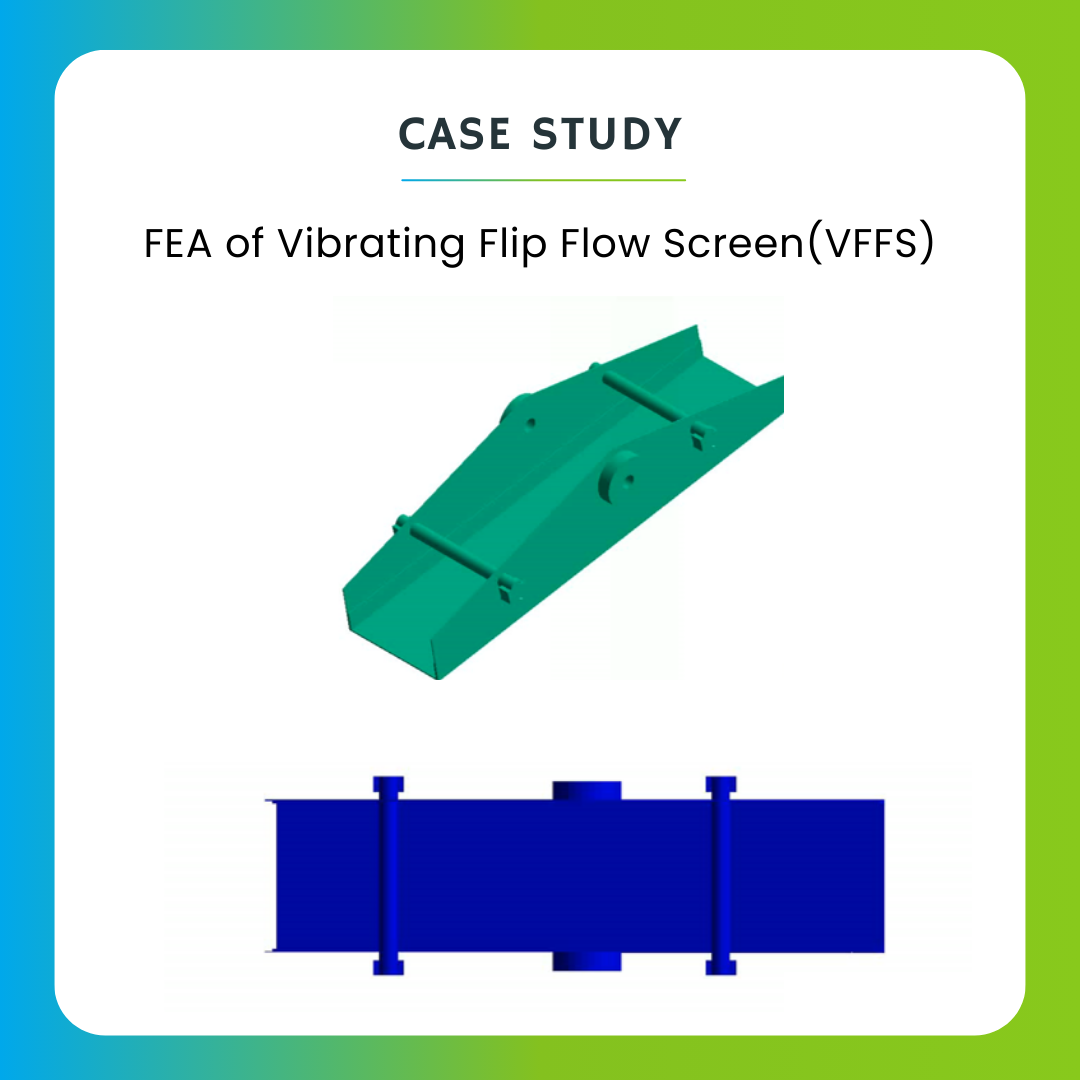

FEA of Vibrating Flip Flow Screen (VFFS)

Efficient separation of materials by size is critical in industries such as mining, recycling, and food processing. The vibrating flip-flow screen (VFFS) offers a unique approach, using flexible screen mats that vibrate and flex to improve particle movement and sorting. To evaluate and enhance its performance, a Finite Element Analysis (FEA) was performed to accurately predict the motion of the system.

Case Studies

Case Studies

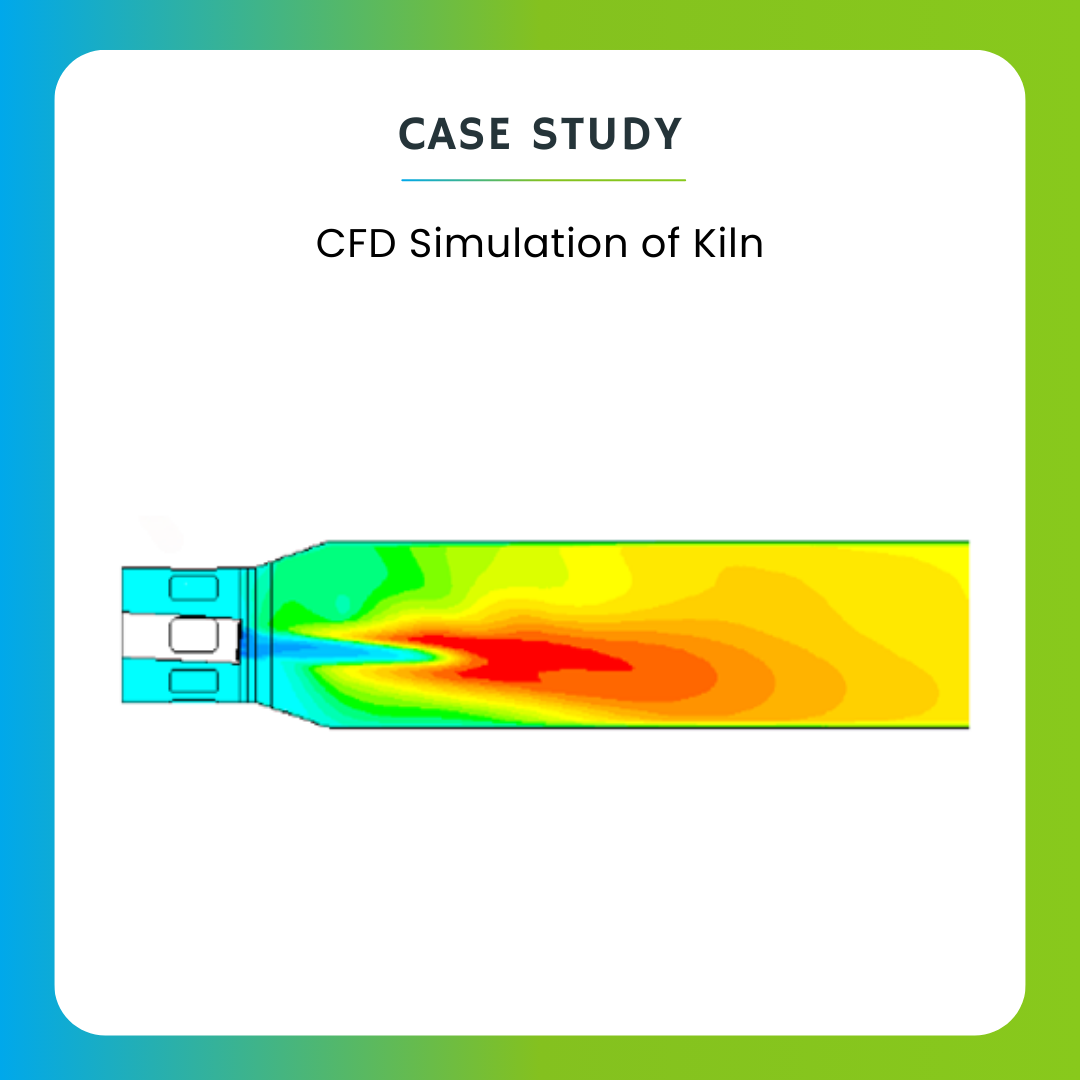

CFD Simulation of Kiln

Controlling emissions while maintaining product quality is a key challenge in rotary kiln operations. During the combustion process in the kiln and preheat zone, high levels of NOx emissions can be generated, requiring optimization of burner design to meet environmental regulations. Using CFD simulations, combustion flame behavior, temperature distribution, kiln wall heat flux, and exit flue gas properties were analyzed.

.gif) Case Studies

Case Studies

FEA to check Structural integrity of the Boiler Main Header and Stub Header

In high-temperature boiler systems, headers serve as vital components for collecting and distributing steam and water, while stub headers act as crucial connecting channels to other boiler elements. These tubular structures are regularly exposed to cyclic thermal loading during cold, warm, and hot startups — making them vulnerable to thermal fatigue over time. To maintain long-term operational safety and performance, it's essential to assess their structural integrity under realistic operating conditions.

Case Studies

Case Studies

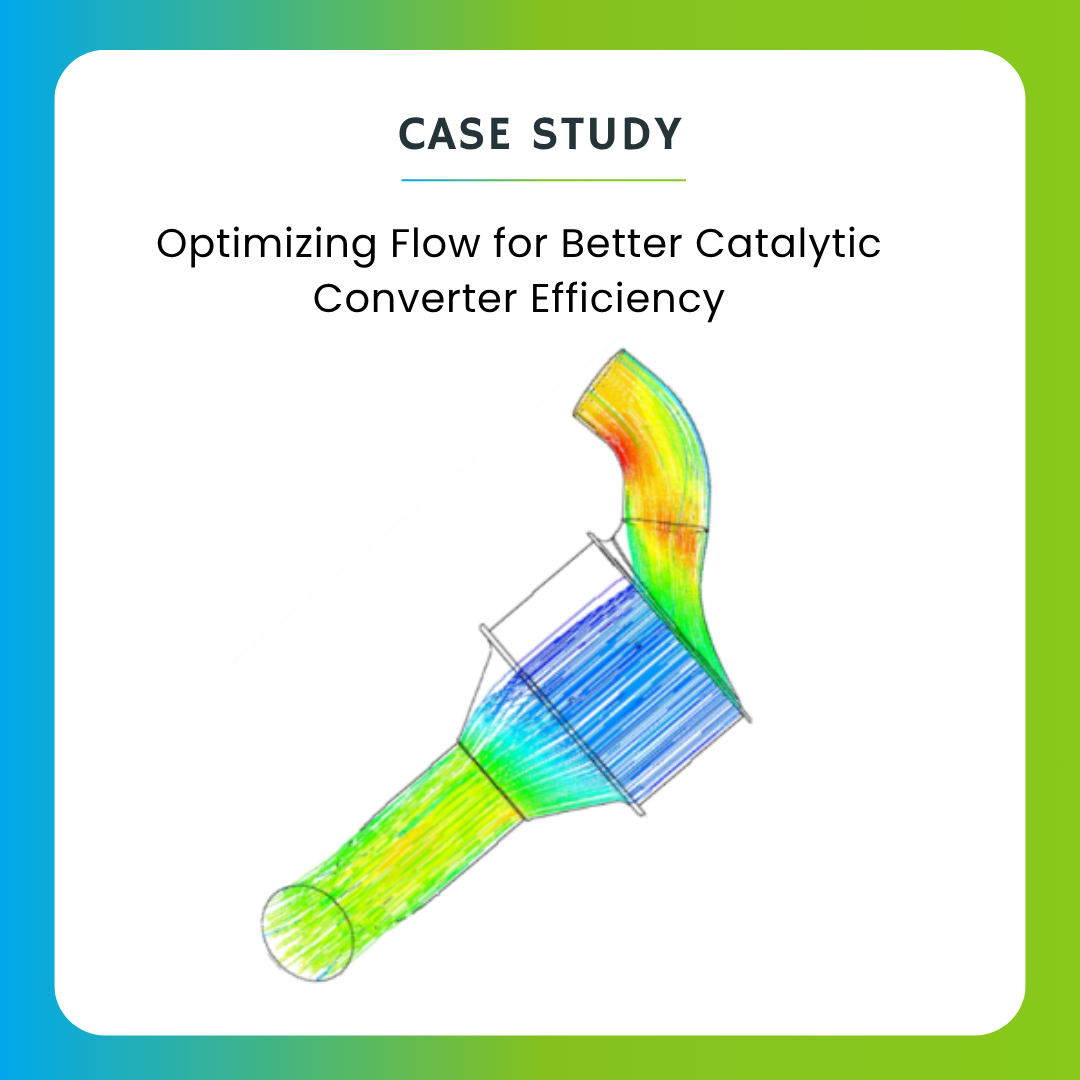

Flow Distribution in Catalytic Converter

Enhancing the efficiency and durability of catalytic converters and combustion systems is critical for optimal plant performance. This case study showcases how Computational Fluid Dynamics (CFD) was used to improve flow distribution in catalytic converters, leading to better pollutant conversion. It also highlights the role of detailed combustion modeling in minimizing thermal stresses and preventing tube failures—ultimately reducing shutdowns and improving operational reliability.

Blogs

Blogs

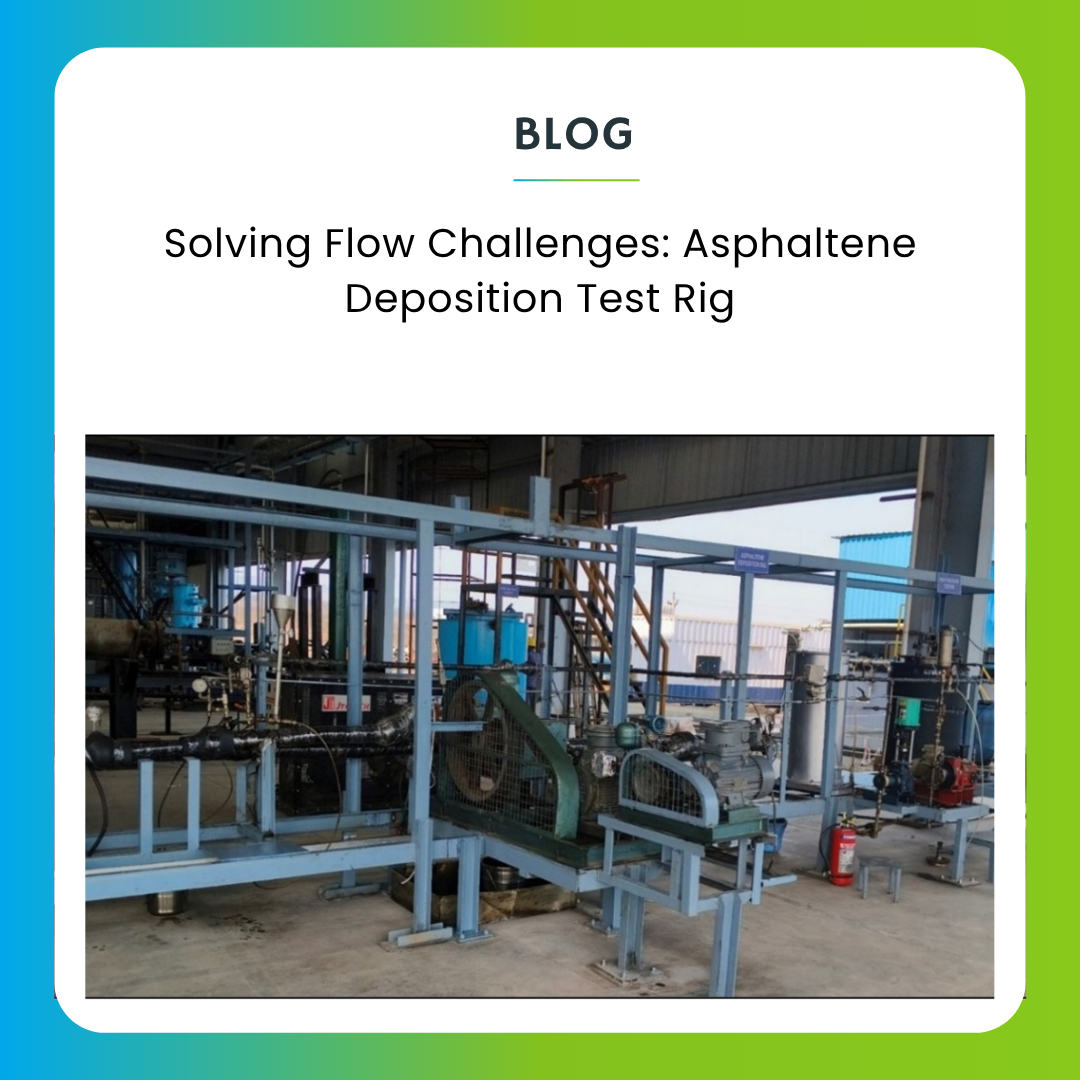

Solving Flow Challenges: Asphaltene Deposition Test Rig

Asphaltene deposition is one of the most persistent flow assurance challenges in the oil and gas industry. When crude oil components interact with precipitants such as n-alkanes (e.g., n-heptane, n-pentane, propane), asphaltenes precipitate, agglomerate, and diffuse toward pipe walls—leading to deposits, clogging, and ultimately reduced production. This problem has cost the industry billions in lost output and well shut-ins. To tackle this issue, we have developed a one of its kind, unique & custom-engineered patented Asphaltene Deposition Test Rig and Procedure for Asphaltene Deposition Analysis and Inhibitor Screening (Indian Patent No. 202221035421) capable of real pipeline conditions with precise control over flow dynamics and chemical environment.

Blogs

Blogs

The Evolution of CFD: A Journey of Innovation, Integration, and Impact

As a consultant in the area of Computational Fluid Dynamics, it is important to review the journey of the technology over last two decades. At Tridiagonal, we have been a part of this journey since 2006 and its fascinating to see the adoption of technology, its spread across industry verticals, use of high performance computing with public and private clouds, use of open source platforms, attempts to make technology reach in the hands of operators and designers and many such developments. This article is a small attempt to highlight the progress across different stages of evolution and extend it to predict how the technology will shape over the next few years…

.gif) Case Studies

Case Studies

FEA of Sheet Metal Forming

Discover how advanced simulation helped eliminate wrinkles and tearing in complex sheet metal forming Stamping of sheet metal is a highly nonlinear and intricate process involving large deformations, contact interactions, and potential material failure. Ensuring proper die design and forming parameters is critical for optimal results. In this case study, Tridiagonal’s Finite Element Analysis (FEA) experts leveraged ANSYS LS-DYNA to simulate the real-world forming operation with precision. The team modeled the complete system, including: Blank holder force application through simulation Accurate friction behavior between blank, die, punch, and holder Realistic representation of material flow and deformation This analysis allowed for early detection of defects like wrinkling and tearing, improving die design and reducing trial-and-error on the shop floor. Download the full case study to see how simulation-driven forming helped improve product quality and process efficiency.

Case Studies

Case Studies

Impact of Projectile on Storage Tank

As LNG storage facilities grow in scale and strategic importance, their exposure to extreme external hazards like hurricane-borne missiles, debris impact, or blast loads has become a critical safety concern. Finite Element Analysis (FEA) offers a powerful solution to evaluate and enhance the structural integrity of large LNG tanks under rare but catastrophic scenarios and help assess the safety and structural integrity of these tanks against these events. Standards like BS 7777 and BS EN 14620 emphasize the need to consider missile impact loads in extreme scenarios. Tridiagonal solutions advanced explicit dynamic simulation techniques, we help LNG operators, EPCs, and designers assess the tank's resilience against high-velocity impacts from airborne missiles or debris — typically generated during extreme weather events or accidental explosions.

Publications

Publications

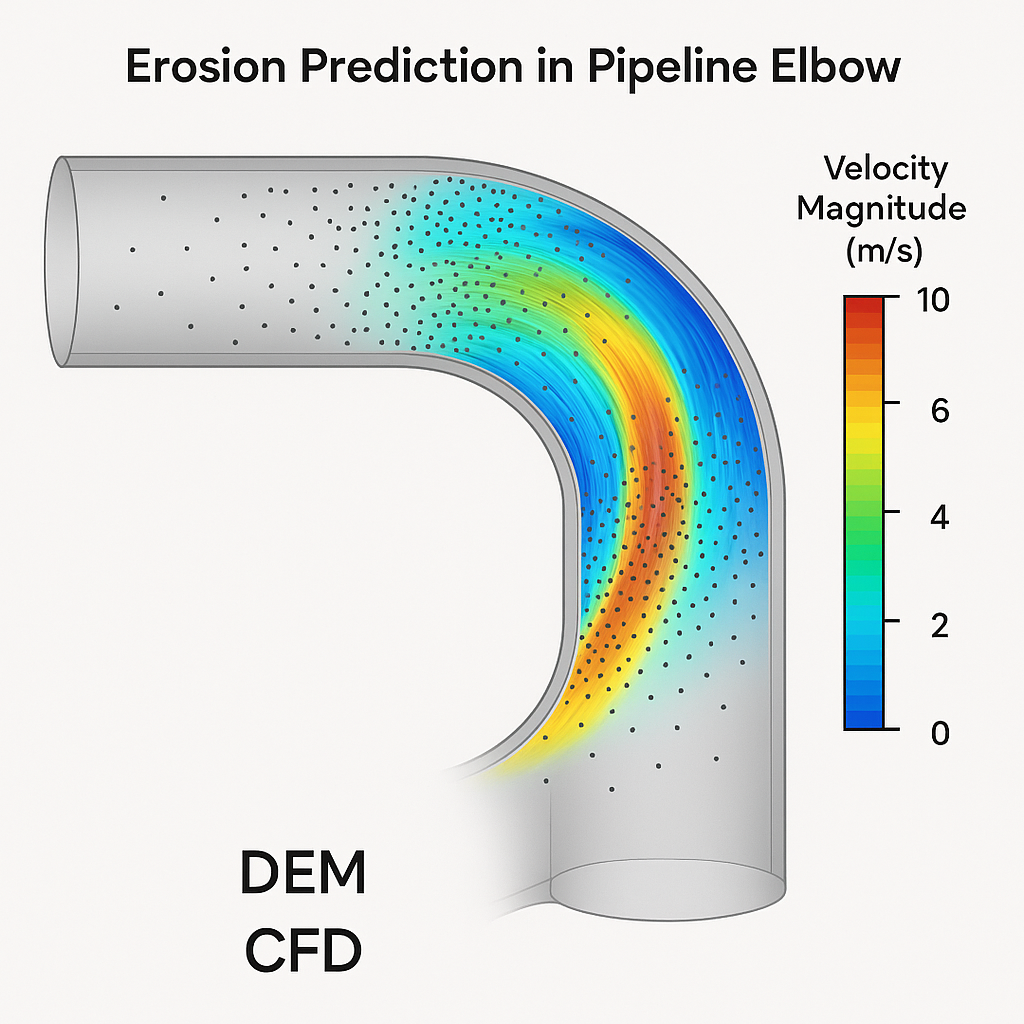

Erosion prediction in pipeline elbow by coupling DEM with CFD

Atul Dubey; R.J. Byron Smith; Damodaran Vedapuri

Case Studies

Case Studies

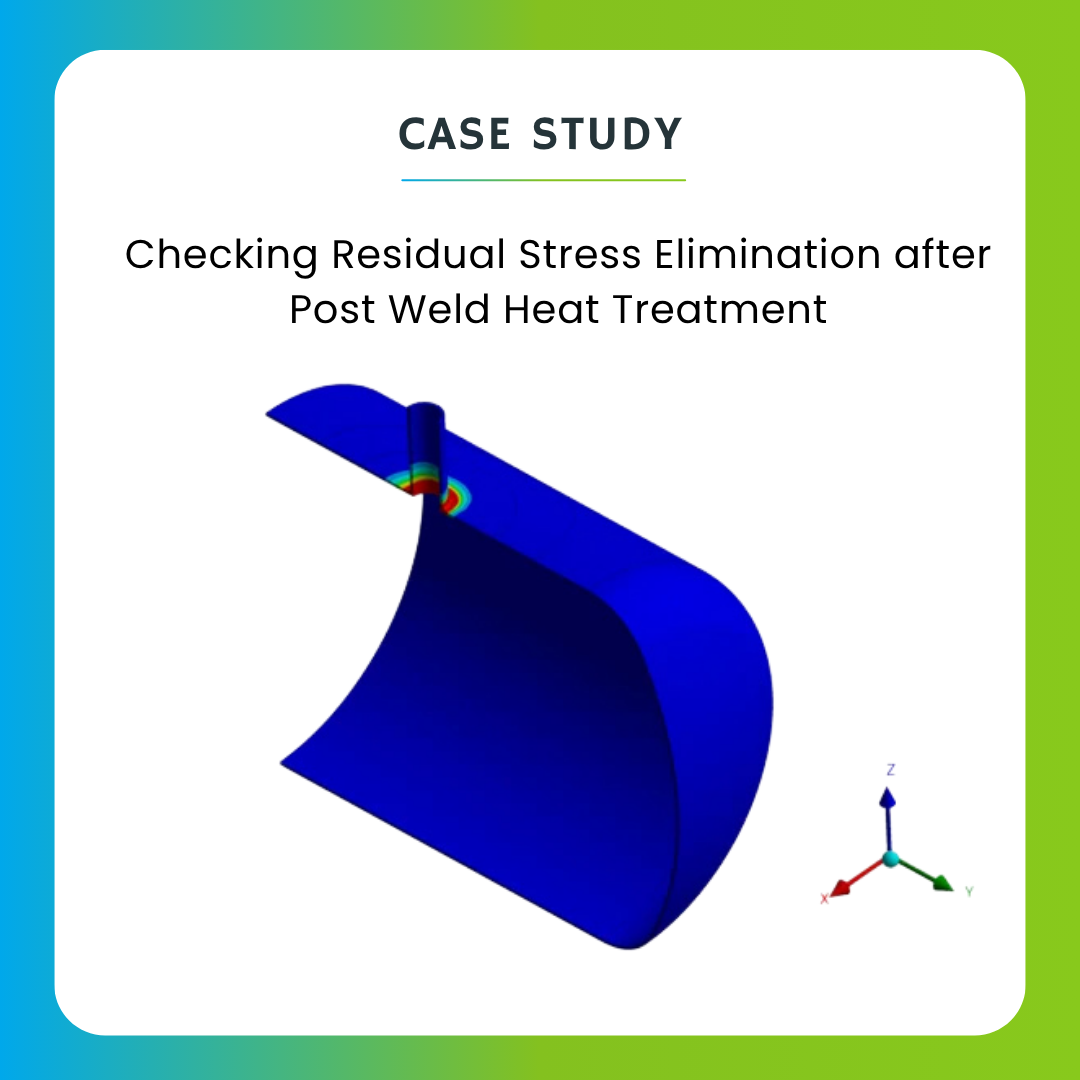

Checking Residual Stress Elimination after Post Weld Heat Treatment

Welding-induced residual stresses in pressure vessels pose significant risks—compromising structural integrity and leading to potential cracking under fluctuating pressure and thermal loads. This makes post-weld heat treatment (PWHT) a critical step in ensuring long-term durability. At Tridiagonal Solutions, our simulation experts developed a Finite Element Analysis (FEA) model that precisely captures the effects of heat treatment using a coupled transient thermal-structural approach. By focusing on critical weld junctions, we assess stress patterns in line with WRC Bulletin 452 and AWS D standards, helping to ensure design reliability and code compliance.

Brochure

Brochure

Erosion of Elbow and other pipe component Testing Facility

Industrial fluid systems, particularly those operating under high-velocity and abrasive conditions, place immense stress on essential components such as elbows, tees, reducers, and 3D pipe templates. Over time, this can result in significant erosion, jeopardizing equipment integrity, shortening component lifespan, and increasing operational risk. Tridiagonal Solutions offers a state-of-the-art Erosion Testing Facility designed to simulate realistic process conditions and evaluate the erosion performance of various stainless-steel grades, alloys, and component geometries. With this data, operators and manufacturers can proactively address weak points in design and material selection before costly failures occur.

Case Studies

Case Studies

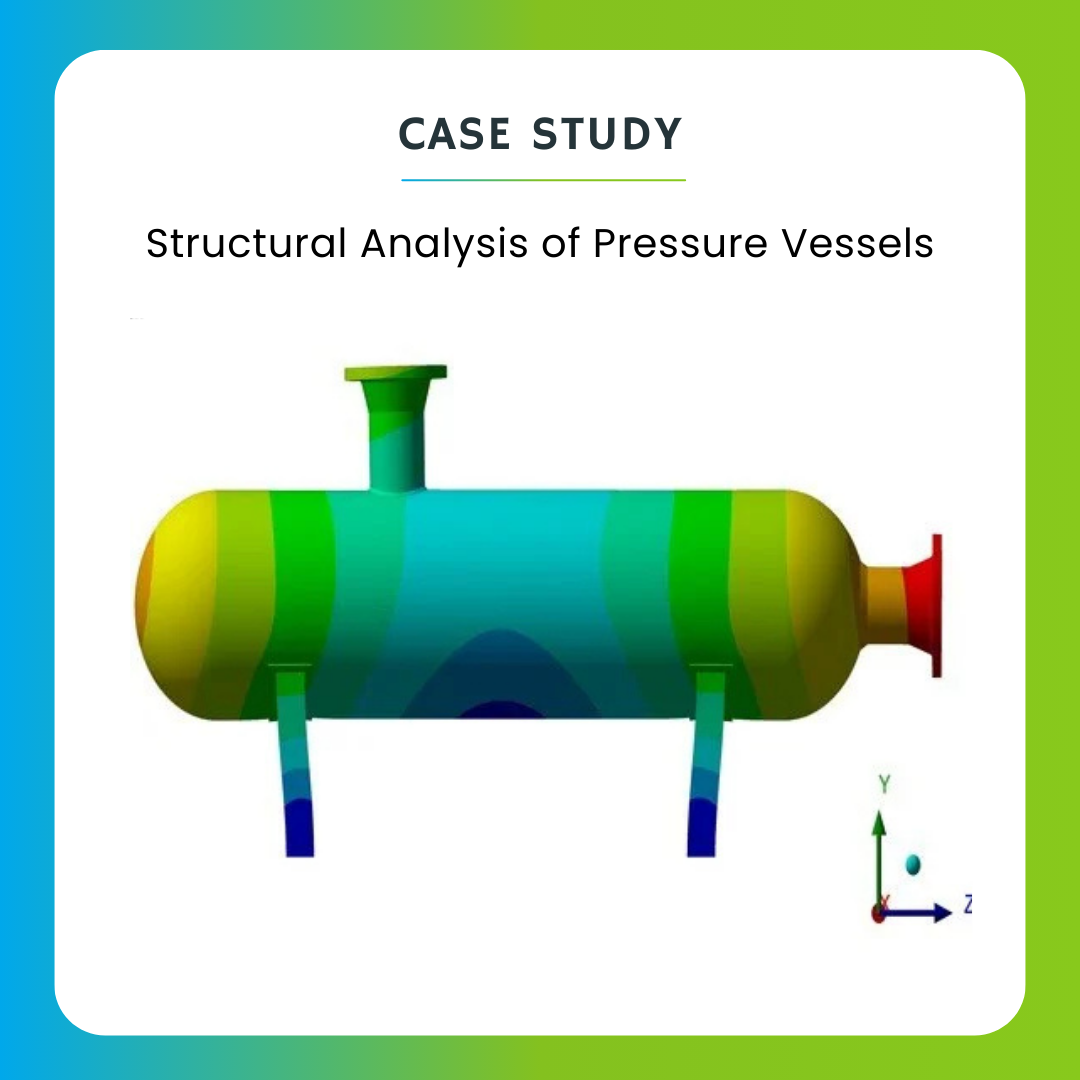

Structural Analysis of Pressure Vessels

This case study presents the structural analysis of pressure vessels to ensure safe and reliable operation under varying process conditions. Using advanced simulation techniques, the vessels were evaluated for stress distribution, deformation, and safety factors against operating loads and pressure fluctuations. The analysis helped in identifying critical stress regions, validating design integrity, and suggesting improvements for compliance with safety standards. See how structural simulation strengthened the reliability of pressure vessel design in this case study.

Case Studies

Case Studies

Three Phase Seperator Tank

Efficient operation of a three-phase separator tank depends largely on how well the phases are separated under gravity. One of the most critical design factors influencing this process is the position and configuration of baffles, which directly affect flow distribution and separation efficiency. In this study, CFD simulations were performed to evaluate the effect of baffle placement and particle diameter on separation performance. The results provided clarity on which design parameters deliver more effective phase separation, enabling improved reliability and efficiency of the separator. See how design insights helped optimize the separation process in this case study.

.png) Case Studies

Case Studies

Office Space Ventilation

Creating comfortable and healthy office spaces requires an HVAC design that balances air distribution with occupant load. Using Airpak simulations, airflow patterns and temperature distribution were analyzed to evaluate thermal comfort and indoor air quality in the workplace. The study provided insights into how air supply, circulation, and load variations impact comfort levels, helping identify design adjustments that improved both efficiency and occupant well-being. 👉 Explore how simulation enhanced office comfort and air quality in this case study.

Case Studies

Case Studies

Multi-Chamber Cooling Sump

Managing flow behavior in cooling sumps is critical to avoid performance losses caused by eddies, vortices, and unwanted swirl formation. Using CFD simulations, the flow distribution and vortex locations inside a multi-chamber sump were analyzed to evaluate the limitations of the existing design.

Case Studies

Case Studies

Solid-Waste incinerator

CFD helps to determine Temperature & O2 distribution. Also to predict Residence time of the pollutants in high temperature & oxygen availability

Case Studies

Case Studies

Scale-up Design of Impeller for Ion Exchange Resin Reactor

Scaling up from a pilot reactor to a large-scale reactor often presents challenges in maintaining performance improvements. In this study, Computational Flow Modeling (CFD) was used to compare the flow behavior, mixing patterns, and overall performance of an existing pilot-scale test reactor with that of full-scale reactor designs.

Case Studies

Case Studies

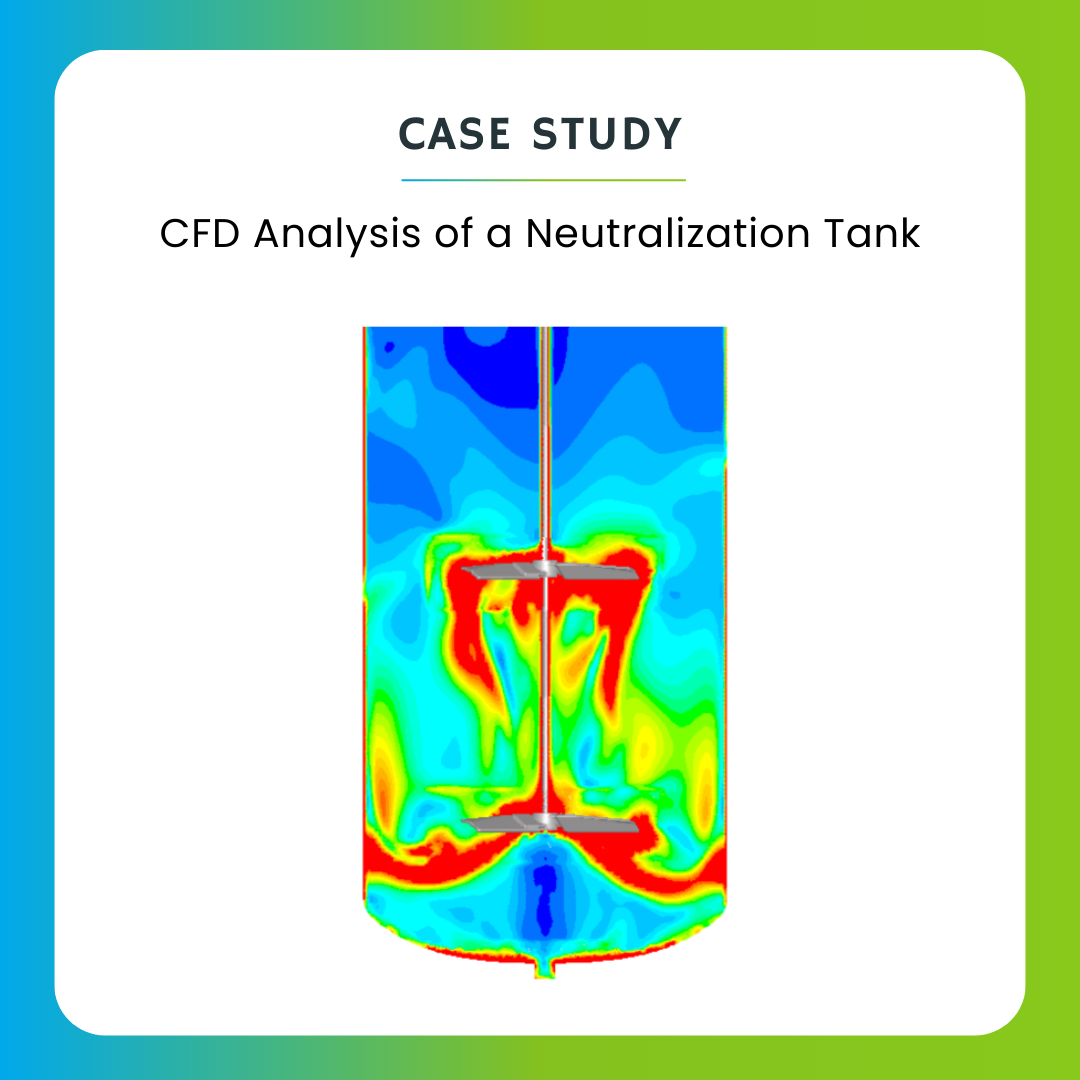

CFD Analysis of a Neutralization Tank

Designing an efficient neutralization tank requires careful evaluation of mixing behavior and flow dynamics. In this project, a new impeller system along with optimized inlet and outlet configurations were developed and tested using CFD simulations. The focus was on studying flow patterns and assessing how acid mixing impacts key performance parameters.

Case Studies

Case Studies

CFD for Cyclone Separator

Efficient gas cleaning is critical in many industrial applications, and cyclone separators are widely used to remove particulates from carrier gases. In this study, CFD simulations were carried out to evaluate cyclone separator performance under varying operating conditions. The analysis focused on how centrifugal forces drive particle separation and how different flow rates and loading conditions influence efficiency. By comparing designs at two distinct loading conditions and gas flow rates, the study provided valuable insights into separator performance and identified opportunities for design improvement. See how simulation enabled deeper understanding and optimization of cyclone separator operation in this case

Case Studies

Case Studies

Evaluate Kiln Ovalization using FEA

Ovalization of rotary cement kilns directly affects the structural integrity of the shell and the life of the refractory lining. Excessive ovality can cause premature refractory failure and impact overall kiln reliability. To address this, a Finite Element Analysis (FEA) was performed to evaluate the degree of ovalization in the kiln shell and benchmark it against allowable limits.

Case Studies

Case Studies

CFD Modeling of Calciner

Efficient calcination is essential for stable kiln operation and product quality. The calciner, positioned in the riser duct between the kiln inlet and bottom stage cyclone, plays a critical role in distributing raw materials evenly to prevent accumulation and enhance residence time. Using CFD simulations, the combustion process was studied under conditions of kiln exhaust gas mixed with tertiary air. The objective was to evaluate calcination efficiency and predict exit gas composition with a reduced tertiary air inlet. The analysis provided valuable insights into airflow, combustion, and raw material distribution, enabling design and operating improvements. Learn how CFD supported optimization of calciner performance in this case study.

Case Studies

Case Studies

CFD modelling of Drug Release through Stent

Stents play a critical role in modern cardiovascular treatment by restoring blood flow in obstructed arteries without the need for invasive surgery. Once deployed, these tiny mesh tubes help keep the artery open, preventing future blockages. Understanding how blood behaves within these vessels is essential not just for mechanical performance, but also for improving drug delivery through drug-eluting stents.

Case Studies

Case Studies

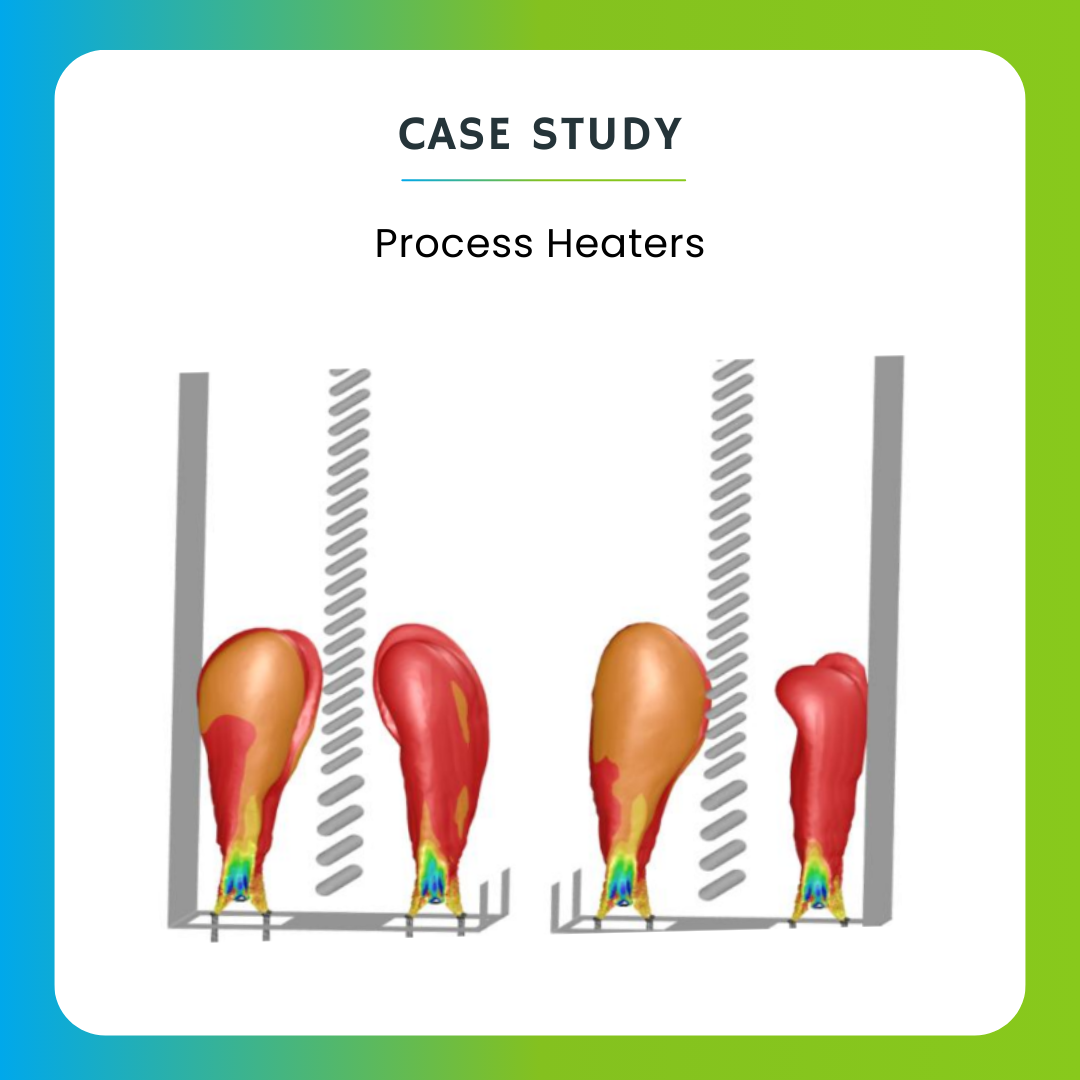

Improving Process Heater Operations using CFD Modeling

This case study focuses on optimizing burner arrangements in a process heater using advanced simulations. By studying the behavior of velocity, pressure, and flue gas flow patterns, the analysis provided a clear understanding of how burner configuration influences heater performance and efficiency. The insights gained helped in identifying improved designs that enhance heat transfer, reduce energy losses, and ensure stable operation of the process heater. Learn how simulation-driven optimization improved process heater performance in this case study.

Blogs

Blogs

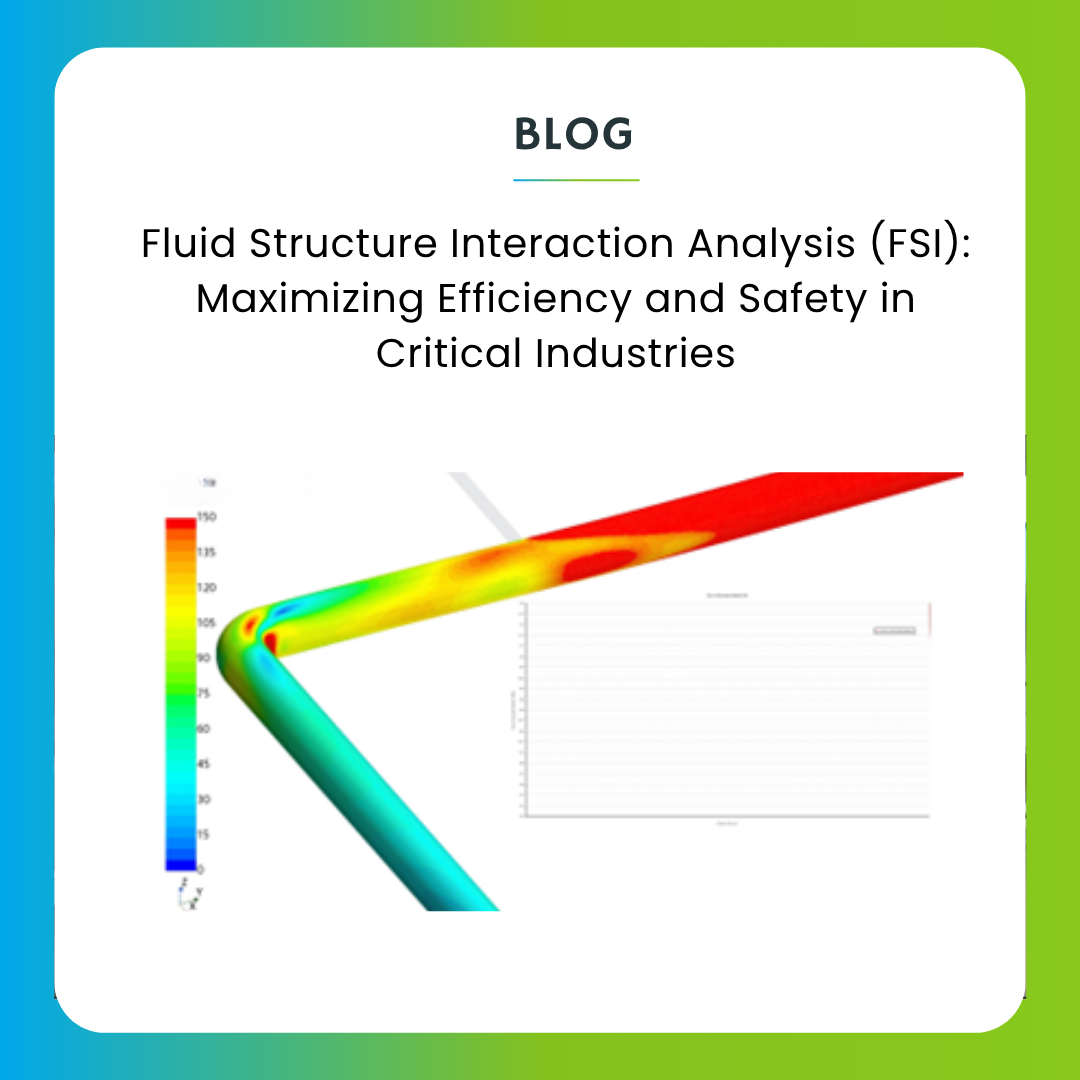

Fluid Structure Interaction Analysis (FSI): Maximizing Efficiency and Safety in Critical Industries

In the fast-paced industrial landscape, the challenges faced by sectors such as oil and gas, crude refining, power generation, and cement manufacturing are immense. Tridiagonal has the key technological advancements that have revolutionized these sectors is the application of Fluid Structure Interaction (FSI) analysis.

.webp) Case Studies

Case Studies

Assessment of FCC stripper vessel as per ASME SecVIII Div-2 code

FCC(Fluid Catalytic Cracking ) is a conversion process used in petroleum refineries to convert the high-boiling point, high-molecular weight hydrocarbon fractions of crude oil into gasoline and other petroleum products. A major player in (FCC) process technology approached Tridiagonal to access structural integrity of the FCC unit.

.webp) Case Studies

Case Studies

Liquid Flashing and Vibration in Storage Tank Feed Pipes

A critical concern for storage tank feed pipes is flow-induced vibration (FIV). This can occur when the liquid within the pipe rapidly vaporizes due to a pressure drop exceeding the liquid's vapor pressure.

.png) Brochure

Brochure

Lab Scale Corrosion Testing

Corrosion, the gradual degradation of materials or metals due to chemical reactions with their environment, poses significant challenges in industries ranging from infrastructure and manufacturing to transportation and energy. To ensure the longevity and reliability of materials, it is essential to employ rigorous corrosion testing methods.

Brochure

Brochure

Control Valve Erosion Testing

Case Studies

Case Studies

Liquid Entrainment and Jumper Study Flow Facility for Hydrate

This multipurpose test facility is utilized to conduct a number of multiphase flow studies ranging from hydrate transport to liquid entrainment. Hydrate mimic studies focus on understanding the impact of hydrate particles on flow regimes transitions and multiphase flow characteristics. Poly propylene particles are used as hydrate mimics. These particles float at the interface of oil and water. Liquid entrainment studies focus on determining the entrainment flux in low liquid loading systems. Starting from onset of entrainment when the first set of droplets are observed in the gas phase to close to a 97% entrainment, these studies focus on how gas velocities impact entrainment flux in both air-water and air-oil systems.

Brochure

Brochure

Asphaltene Deposition Facility

Asphaltene deposition remains one of the most persistent flow assurance issues in oil and gas production. These complex, heavy organic molecules can quickly accumulate, clogging flowlines, damaging equipment, and significantly reducing production efficiency. The challenge? No single mitigation strategy works across all reservoirs or crude types. Asphaltene behavior is highly dependent on the oil's composition, reservoir pressure and temperature, and even the effectiveness of chemical inhibitors varies widely. At Tridiagonal Solutions, we recognize the need for tailored solutions—not generalized fixes.

Case Studies

Case Studies

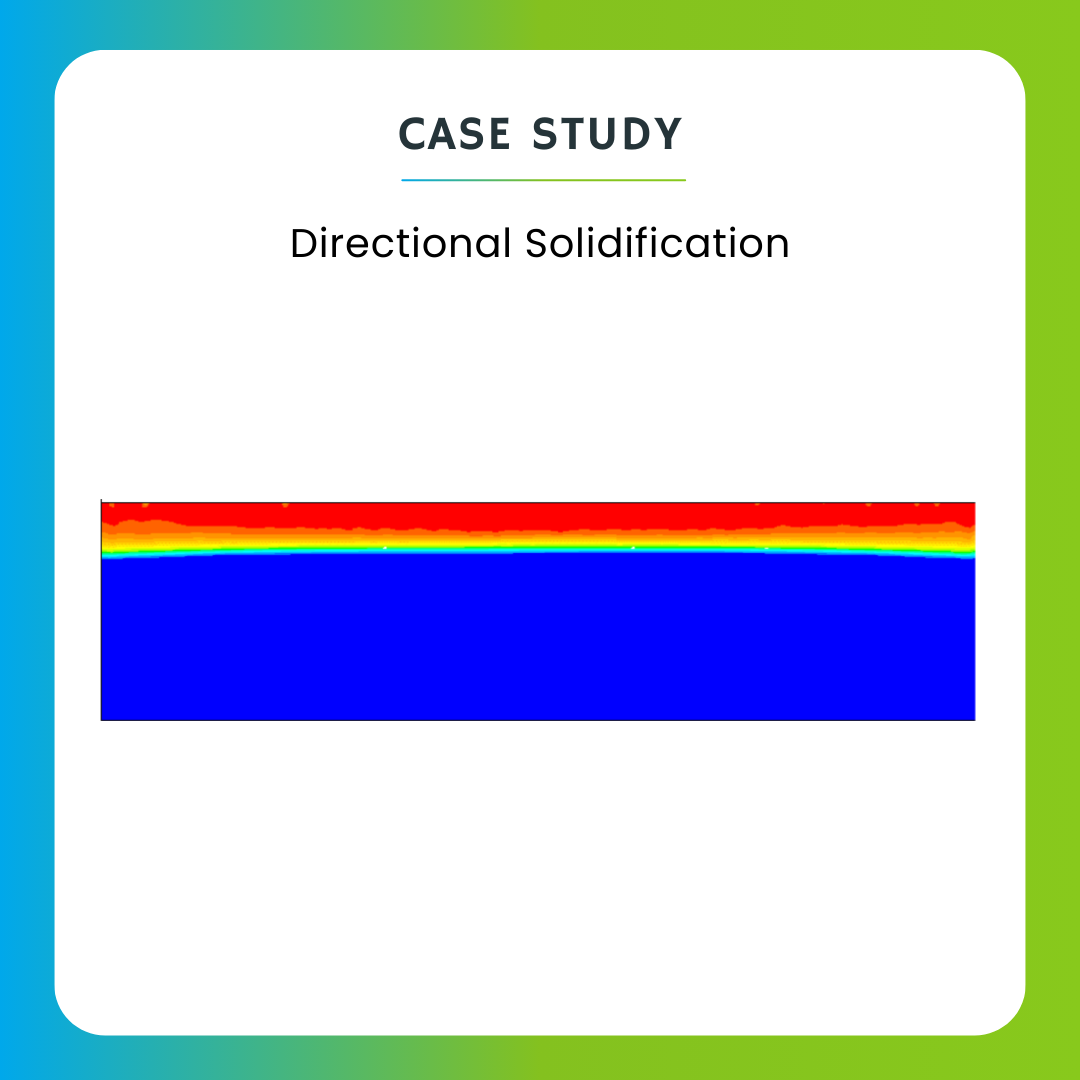

Directional Solidification

Designing a Directional Solidification System (DSS) involves addressing the complex interaction between fluid dynamics, heat transfer, and crystal growth. In this study, advanced simulations were applied to evaluate critical phenomena influencing system performance, including phase change, unsteady multi-component flows, heat transfer with radiation, natural convection, and mild turbulence over the melt surface.

Case Studies

Case Studies

Mixing Studies

Embark on a journey into the heart of our technological expertise, Mixing Facility. In the realm of the Chemical sector, optimizing tank configurations for increased yields is paramount. Challenges arise in determining the optimum configuration of mixing tanks, selecting the appropriate impeller type, impeller position, and impeller clearance to enhance yields through the mixing process without generating unwanted vortex.

Case Studies

Case Studies

Development of Gas Void Fraction Sensor System

Understanding in situ gas volume fraction is critical for optimizing gas-liquid systems, especially in complex flow regimes. While overall gas holdup measurement is relatively simple, accurately capturing local gas holdup remains a significant challenge due to system opacity and noise interference.

.webp) Case Studies

Case Studies

Foam Transportation Loop

In the realm of multiphase flow dynamics, understanding the intricate behavior of foams is essential for numerous industrial applications, particularly in the oil and gas sector. Tridiagonal's Foam Transport Facility stands at the forefront of this research, providing a state-of-the-art platform designed to delve into the complexities of foam generation and breaking mechanisms. This facility features a substantial 16-inch diameter, -foot-long flow loop, incorporating advanced mesh-type assemblies and comprehensive visualization sections. By generating foams using various surfactants and studying their behavior under diverse flow conditions, the facility offers unparalleled insights into foam dynamics.

Case Studies

Case Studies

Aeration and Foaming during Bottle Filling

Aeration and foaming during the bottle filling process can lead to significant product losses, underfilling, and operational inefficiencies. This case study presents experimental investigations conducted to understand the fundamental mechanics of aeration and foaming under various liquid properties and operating conditions.

Case Studies

Case Studies

Coffee Bean Dryer

Project aimed to create an efficient drying process that would not burn the coffee beans. To achieve this, Tridiagonal created a computational fluid dynamics (CFD) model and conducted a pilot plant proof of concept at TRL-3.

Case Studies

Case Studies

Paraffin Wax Stripping in Field-Scale Pipelines

Paraffin wax deposition in pipelines is a persistent challenge in crude oil transport, affecting flow efficiency and increasing maintenance costs. This case study explores the effectiveness of paraffin wax stripping under various operational conditions using a full-scale experimental pipeline setup.

Sand Control Screen Erosion and Flow Performance

Effective sand management is critical to ensuring the longevity and performance of oil and gas wells. Uncontrolled sand production can cause severe erosion in downhole equipment, leading to increased OPEX/CAPEX and reduced well productivity. This case study focuses on evaluating the erosion resistance and flow performance of sand control screens—key to retaining formation particles while enabling efficient fluid flow into production wells. Leveraging Tridiagonal’s advanced test loop setup, which includes a 2200 cfm gas compressor system (up to 7 bar pressure), and an in-house sand screw feeder (50–2000 g/hr dosing), comprehensive tests were conducted under realistic conditions. Additional capabilities like laser particle size distribution (PSD) analysis and Maximum Pore Passage (MPP) testing per API 19SS guidelines enabled precise performance evaluation. Download the full case study to explore how real-world testing and data-driven insights support the development of more robust, efficient sand control solutions for enhanced well performance.

.png) Case Studies

Case Studies

Multiphase & Single-Phase Flow Study for Sand Transport in Inclined Well

Understanding sand transport behavior in oil and gas wells is essential for designing effective sand management strategies. This case study presents a pilot-scale experimental loop designed to replicate wellbore conditions using tubular test sections with the same diameter as actual well designs, albeit at shorter lengths. The setup allows for both single-phase and multiphase flow studies to evaluate sand transport in inclined wells under realistic operating conditions.

-1.png) Case Studies

Case Studies

Liquid metal Transport

Mercury contamination in oil and gas pipelines poses serious challenges—leading to pipeline corrosion and environmental hazards due to biomagnification in marine ecosystems. This case study investigates the gas-assisted transport of liquid heavy metals, like mercury, to enable effective removal from pipelines.

.png) Case Studies

Case Studies

Erosion-Corrosion Testing

Erosion-corrosion experiments are pivotal for understanding the degradation processes in larger pipelines like 4-inch diameters, offering insights into the combined effects of both erosion and corrosion under real-world conditions. These insights are crucial for predicting and mitigating pipeline failures, guiding the development of robust materials and coatings, and optimizing maintenance strategies to ensure the safety, integrity, and longevity of larger pipelines.

Case Studies

Case Studies

Erosion Testing Setup

Tridiagonal Organization specializes in providing innovative solutions for various industries, including Oil & Gas, Pet Chemicals, Pharma, Food, Metals & Mining, Cement, etc. In these industries, equipment such as SS elbows, tees, reducers, and 3D templates are subjected to harsh operating conditions, including high velocities of abrasive fluids, which can lead to erosion. Erosion is a critical issue that can compromise the integrity and longevity of industrial components, resulting in costly repairs, downtime, and safety hazards. To address these challenges, Tridiagonal Organization has established a comprehensive erosion testing setup to assess the erosion resistance of its products and optimize their design and material selection.

Case Studies

Case Studies

Automated Inflow Control Device Erosion Testing Facility

Inflow Control Devices (ICDs) and Automated Inflow Control Devices (AICDs) are critical in enhancing well performance, balancing reservoir inflow, and minimizing unwanted fluid production. Tridiagonal Solutions offers a fully equipped testing facility designed to rigorously evaluate these devices under realistic wellbore conditions. Our testing portfolio includes cavitation testing, flow performance analysis, erosion resistance, and mud flow initiation and sediment plugging assessments—all in alignment with API 19ICD specifications. By simulating both single-phase and multiphase flows at pressures up to 200 bar, we deliver actionable insights to optimize device design and reliability in field deployment.

Case Studies

Case Studies

SMX Static Mixer

Static mixers (SMX) are compact and efficient devices, but they often face challenges such as ensuring uninterrupted mixing of viscous liquids, achieving uniform blending, and maintaining effective heat and mass transfer. To address these, CFD simulations were carried out to evaluate flow patterns and particle distribution in SMX mixers.

Case Studies

Case Studies

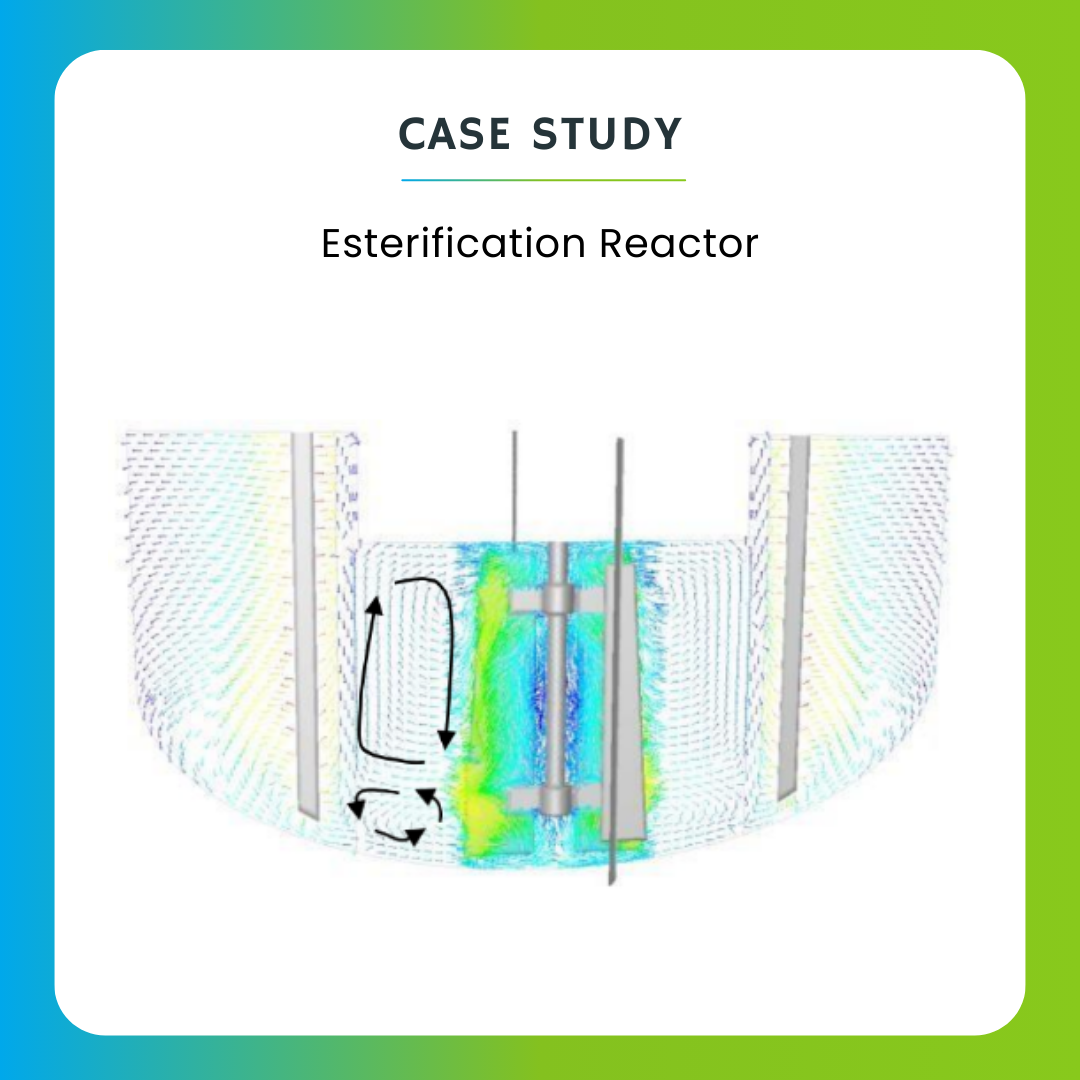

Esterification Reactor

This case study demonstrates how Computational Fluid Dynamics (CFD) was applied to analyze the performance of an esterification reactor under its existing configuration. The simulations provided detailed insights into fluid flow patterns, particle trajectories, mixing efficiency, and circulation behavior within the reactor. Special attention was given to evaluating circulation time distribution (CTD) and residence time distribution (RTD)—two critical parameters that directly influence reaction efficiency and product yield.

.png) Case Studies

Case Studies

Impeller Design – PSD

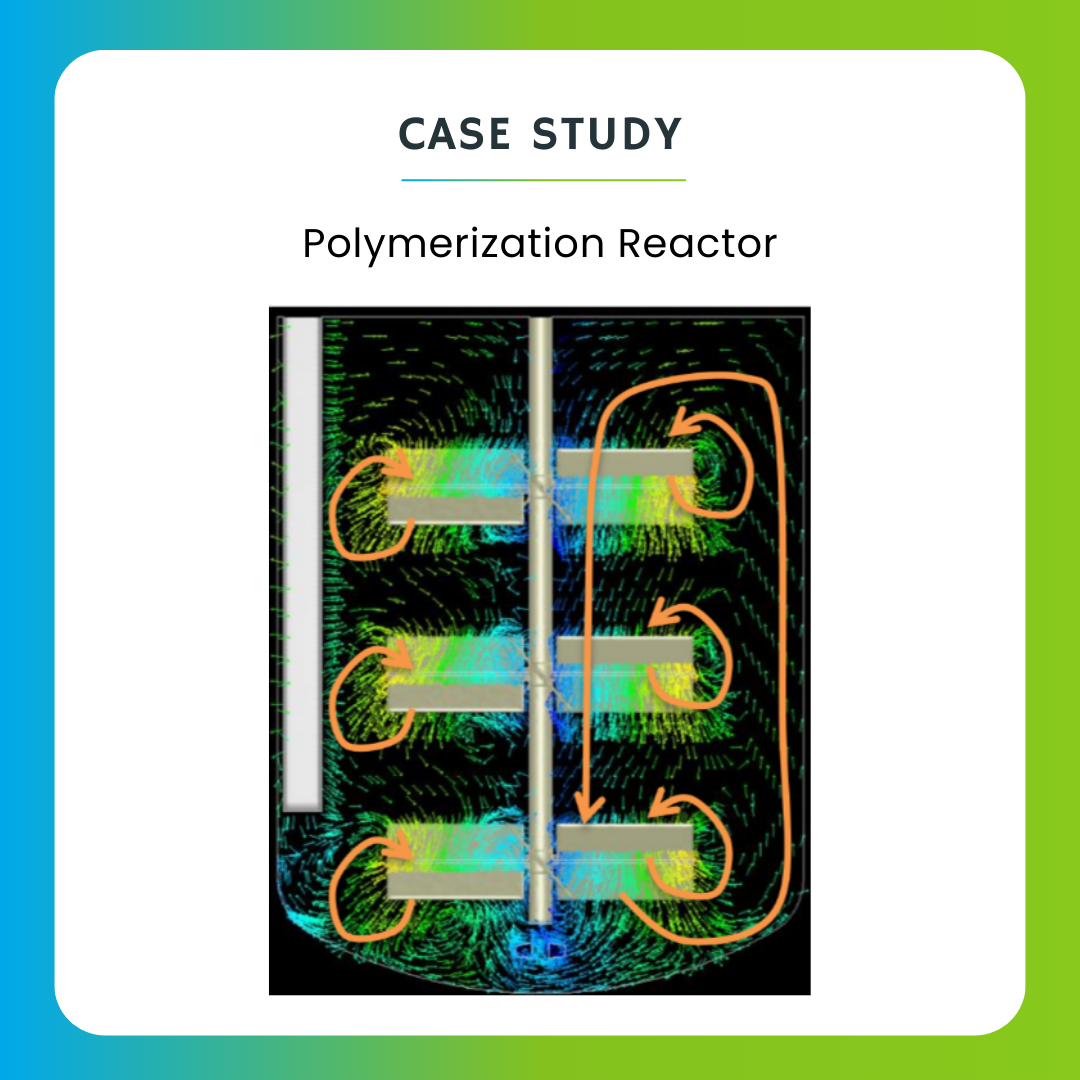

This case study focuses on the simulation and evaluation of impeller designs in a polymerization reactor to improve overall performance. The existing impeller was modeled, and several alternative designs were developed and analyzed to understand their impact on mixing dynamics. Detailed plots of strain rate distribution and Particle Size Distribution (PSD) were generated to compare performance across configurations.

Case Studies

Case Studies

Design of Polymerization Reactor with PSD-Driven Insights

This case study highlights how CFD simulations were applied to improve the manufacturing process of ion exchange resins involving poly-dispersed bead sizes. The team analyzed the reactor’s operating conditions to understand how particle size distribution (PSD) affects strain rate distribution and mixing behavior. By simulating multiple design scenarios, it became possible to visualize performance bottlenecks and identify areas for optimization. Through this approach, suitable design modifications were suggested that enhanced mixing uniformity, reduced localized stress, and boosted the reactor’s overall efficiency. These insights support more reliable scale-up and consistent resin quality in industrial production. Get the full case study to uncover how simulation-driven design led to measurable reactor improvements.

.png) Case Studies

Case Studies

Asthma Inhaler

The performance of a dry powder asthma inhaler was evaluated using advanced CFD simulations. The study focused on an inhaler design that included an inner obstruction and a filter near the mouthpiece—two critical features influencing airflow and particle dynamics. By simulating real operating conditions, the analysis provided a detailed understanding of how these design elements impact overall inhaler efficiency and drug delivery performance. Key performance characteristics such as aerosol efficiency and maximum particle size distribution were assessed to determine the effectiveness of the device. The insights gained from this study help in optimizing inhaler design for improved patient outcomes and regulatory compliance. Explore the complete case study to see how CFD enabled deeper design validation.

Case Studies

Case Studies

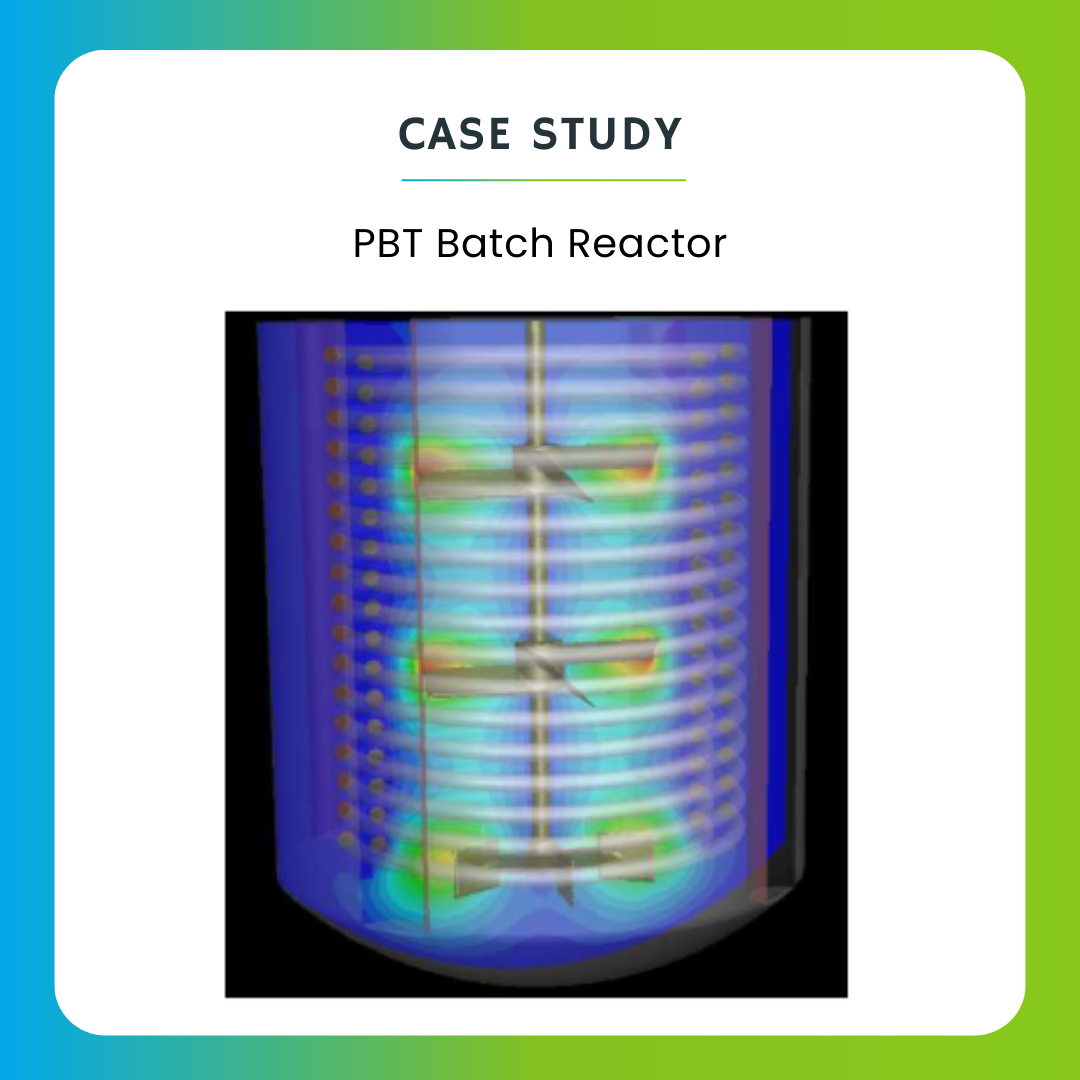

PBT Batch Reactor

A steady-state CFD simulation of a pharmaceutical batch reactor equipped with two 45° Pitched Blade Turbines (PBT) and a six-disk turbine was performed to evaluate power number and fluid phase mixing characteristics. The study provided insights into mixing efficiency, hydrodynamics, and energy requirements—helping optimize reactor performance for pharmaceutical applications. Download the full case study to explore detailed results and key design learnings.