Tridiagonal Solutions offers dry gas and slurry erosion testing for downhole sand control screen coupon as well as 3D screen test fixtures of various types such as Premium Mesh, Wedge Wire, Ceramic coated screens etc. The results of erosion tests are being evaluated on basis of screen weight change data, flow performance data, Maximum Particle Pass, pin/filler gauge measurements and Microscopic/Light table Images of erosion hotspots as per API 19 SS allowing operators select right screen for their completion well.

Related Use Cases

Brochure

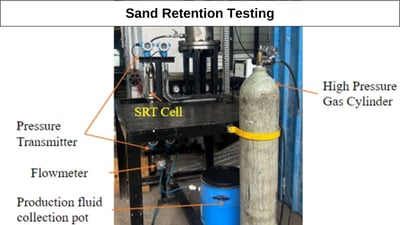

Sand Retention Testing

Use Cases

Sand Control Screen Erosion and Flow Performance

Publications

Multiphase Flow Pattern and Screen Selection: Two Overlooked Parameters...

Use Cases

FEA of Vibrating Flip Flow Screen (VFFS)

Have a Question?

If you need assistance beyond what is provided above, please contact us.