Life Sciences/Pharma

Dx in Process Manufacturing

Industry Overview

With the growing demand for global medicinal drugs, industries face the necessity to optimize their overall costs to sustain and meet market needs. Additionally, market dynamics require continuous improvement through the identification of opportunities to optimize equipment running costs and raw material expenses by maximizing utilization to achieve optimal production levels. Data-driven techniques have proven effective in enabling companies to enhance the performance of their shop floor processes and assets in real-time.

Dx Opportunities

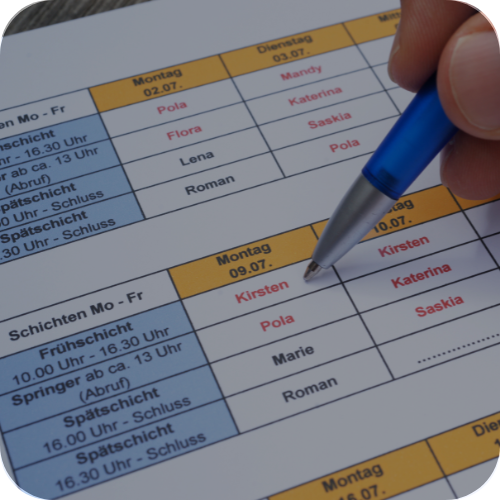

Ensuring quality assurance and optimal production levels is often challenging, subordinated with lot of dependencies associated with the nature of the batch operations itself. “Quality is never in real-time!” – makes it even more difficult for the engineers to make effective decision. Informed decision making is critical to prioritize and ensure consistent batch product quality, maximize utilization and optimize OEE. This demands for continuous monitoring and tracking of the KPIs of which some are measured, some are siloed and some are derived. Using our value based offerings for life-sciences, organization can reap the benefits in the following areas below:

Optimizer the overall carbon footprint through digital intervention by optimizing the fuel, water and steam consumption across entire site operations. Real time optimization of the utilities operations including boilers, HVAC, air compressors, CIP and others.

Energy Management

Energy prediction and management across site including the utilities is key for improving the overall energy efficiency of the operations. For a production facility, it is important to operate at the optimal level to ensure that overall energy, steam, water consumption per unit production are minimum as per the predictions. Tridiagonal solutions tailored frameworks enables the organizations to have a deeper and meaningful insights about energy KPIs across the facilities. Thes solutions are curated to deliver the best-in-class solution to bring about the visibility of various energy sources and sinks using the hybrid approach leveraging first principles and data driven techniques.

.png?width=398&height=393&name=Capabilities-1%20(1).png)

KPIs such as steam to fuel ratio is an important metric to allow the frameworks to identify the opportunities for optimization. Correlate the best possible fuel combination strategy with the predicted CV against the target steam production.

Changeovers and workovers in the batch operations are critical to determine the performances of the future production. It is important to manage the effectiveness of the steam and solvent cleaning to ensure the consumption of the resources are consumed optimally without compensating on the quality and production targets

Chillers are one of the major energy consumers in pharma or lifescience sector. It is important to predict the energy consumption in correlation with input water and output water conditions. AI models can integrate the humidity and temperature control to provide deeper insights in the set point changes for improvements in the energy efficiency.

Track and monitor the steam efficiency at equipment and site level operations. Predict the required amount of steam using first principles and benchmark it against the actual steam consumption. Track the overall steam economy across various unit operations and process across site, starting with Boilers to turbines and reactors in processing facilities.

Improving the OEE and utilization of the batch assets and reducing the unplanned downtimes in the critical operations including utilities for maximum productivity.

Predictive maintenance

Maintaining the availability for the desired period of uptime is one of the most important task for the production to run continuously to meet the market requirements. Critical assets spans from compressors to exchangers to reactors and dryers. Unforeseen operating conditions makes it difficult for the operators to understand the dynamics around the health of the equipment. Several factors including deviations in KPIs to seasonality variations lead to unplanned downtimes in the critical assets. With our expertise in dealing with rotating assets, it has been made possible to leverage the physics augmented data driven techniques to track the anomalies and deviations in the assets which can cause the chances of failures. With the predictions organizations can see multiple benefits in planning the maintenance activities to reducing the overall inventory costs.

Air compressors are one of the most critical operations to ensure the production is met at their desired level of targets at minimum operating cost. Using this solution reliability team can predict the performance (Isentropic and polytropic) and health in real time. These modules helps the team to predict the possibilities of failures with the deeper insights about the failure modes and prescriptions.

Autoclave machines are critical for sterilization processes. With the changing bioburden of the feed materials the performance of the autoclave reactors are prone to deteriorate. With AI models operators can predict the potential of anomalies in the machine before operating the next batch, which allows them to prioritize the maintenance activities without letting the batch to fail abruptly.

Using the batch unfolding techniques, transform the times series parameters to batch wise sequences. Correlate the transformed dataset with the health score of the batch to determine the performance of the next batch providing the information about the maintenance needs required before next production batch.

For CPG manufacturers maintaining the availability of the batch assets is second to none. Maximum availability enables them to produce more with the same resources. OEE and utilization KPIs derived based on predictive algorithms provides the visibility of the these in real time and allows the operators to continuously improve their operations.

Soft sensors for prediction of the lab measurements for the critical batch operations such as drying, bioreactions, filtration and separation. Improving the control strategy for batches with real time visibility of lab parameters.

Predictive quality

Quality management for various entities including feedstocks to fuels and product is important to produce with satisfactory level of quality standards. Most of quality variables are recorded based on the lab sampling at certain low frequent intervals, which makes it difficult for the control room operators to take the real time corrective actions. With inferential modeling process operators can gain deeper insights about the set point control changes required for achieving the optimal quality specifications. Physics driven inferentials can enable with real time prediction of quality variables for critical catalytic reactions, distillation and other processes.

.png?width=398&height=393&name=Capabilities-3%20(1).png)

Using physics-based AI to predict the quality parameters such as yield and conversion in real time. Model using the historical low frequency lab reading against the set of operating variables to develop the correlation between the two. Use the recommended changes in the set points to control the quality variations.

Predict the sulphur content in real time to prevent any catalyst degradation and process upsets. Inferential models the % sulphur content at any given point in time to control the process dynamics promoting unwanted deviations.

Maximizing the recovery of oil in water during the skimming operations is crucial. Typically such sampling is time expensive task. AI can enable the prediction of oil in water in real time with changing operating scenarios and fluctuating crude compositions.

Optimize of the raw material consumption and batch KPIs such as cycle time, conversion improvements in real time using hybrid modeling approach.

Process optimization

Minimize the grade transition period and product off-specifications through AI based prescriptive analytics. Operate at the maximum possible efficiency with optimal cycle time in order to improve continuously. Optimize the cycle time and yield of batch and continuous processes through AI-based optimization toolbox. Leverage the AI based simulators to continuously identify the opportunities to optimize the control strategy to meet the desired product specifications at minimum operating costs.

Cycle time optimization paves the way to identify the opportunities to improve the operations. AI with the embedded information about the batch recipe enables tracking of the KPI deviations in real time. Operators can benchmark the real time batch activities against the threshold duration to correct the deviations in real time to prevent batch rejections and optimize the batch KPIs

Hybrid models enables physics informed AI to identify the opportunities in improving the product yield in real time. Model captures the non-linearities, intermittent feed addition to dynamically recommend the set point changes to predict the incremental yield.

Batch operations demand for optimal raw material utilization, optimal cycle time and optimal levels of yield. Golden batch analysis allows the operators to benchmark the batch KPIs against the best historical batches enabling them to run at the closed possibility against the golden runs.

For efficient operations of the centrifuge machines, it is important to maintain the operating conditions at various batch phases at optimal level. AI can capture the dynamic changes in the feed from bioreactor and recommend the appropriate set points to maintain the turbidity of the product stream within the desired specifications.

For the dryer operations to run optimally it is important to monitor and track the KPIs in real time. LOD prediction while batch is in progression can allow the operators to make the desired changes to achieve the target product specifications at the end of the batch

Leverage the zero shot and few shots LLMs to interpret and analyze the unstructured dimensions. Integrate the interpretation from quality reports, product compliance report, incident reports and many others for improving the productivity and gaining deeper insights about the operational dynamics.

Generative AI

More than a quarter of data remains unused as it becomes difficult to access and interpret them due to its unstructured and non-standard formats. Documentation spans from raw materials information, production reports to quality and compliance records. Generative AI can be leveraged to automate the interpretation of the information using the zero shot and few shots LLMs to interpret and analyze the unstructured dimensions. Integrate the interpretation from quality reports, product compliance report, incident reports and many others for improving the productivity and gaining deeper insights about the operational dynamics.

In order to continuously improve the batch performances it is important to extract many unstructured information such as visual and physical characteristics of the product from the certificate of analysis reports. Usually such information are available in siloed unstructured documents. LLM models can be leveraged to extract and derive meaningful insights from these documents to provide the intelligence to the operations team

Alarms are critical to be monitored and categorized in several priorities. With the LLMs unstructured alarm reports can be segregated based on its criticality and frequency. These models can augment advanced analysis intelligence to estimate and correlate the information with process parameters

Improve the interpretability with meaningful insights derived from the historical RCA reports. Real time anomalies can be correlated with the historically similar events with the added intelligence about the indicators and corrective actions.

Use Cases

Despite of the ever-growing market and dynamic changes digital is still harnessed to catalyze the solutions for various industrial challenges across the value chain. Find below the list of use cases specific to shop floor interests addressing various challenges encountered within the life science and pharmaceutical sector:

Accelerate your Dx transformation projects with Smart Apps and Time-to-value (TTV) program

- Smart Apps

- TTV A-33 Program

Deploy smart apps for Golden-batch analysis, Batch-to-batch comparison, Bioreactor Yield prediction, OEE and predictive maintenance of critical assets (Centrifuge machines, Reactor, Lyophilizer, Tablet Press machine, Granulators, etc.), Soft-sensor for real time quality prediction, HVAC and air Compressors energy optimization, Gen AI for manufacturing, etc.

Time to Value program leverages advanced scalability frameworks to deliver superior analytics solutions to manufacturing industries. Designed for rapid implementation, our program ensures larger delivery with unparalleled speed and efficiency. By utilizing scalability frameworks, we significantly reduce the time and cost associated for standard approaches. and accelerates deployment, allowing manufacturers to quickly gain insights and drive improvements in their operations. With our program, clients benefit from faster, data-driven decision-making, enhanced productivity, and a swift return on investment, making it the optimal choice for modern manufacturing analytics projects.

Why Tridiagonal?

Looking for Trusted Partner for executing your programs?

We bring together unparalleled expertise with combination of skillsets and technology to address your digital, computational and testing needs

.webp)