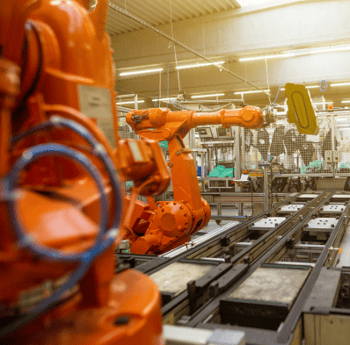

Digital Transformation in Process Manufacturing

About Practice

Tridiagonal Solutions Pvt. Ltd. (TSPL) is an Industry 4.0 solutions and implementation consultant, leveraging Industry 4.0 tech stacks to implement Manufacturing Excellence and Digital Transformation solutions. We bring combination of tools, techniques, expertise, and solutions to support various initiatives (such as APM, APC, Digital Twin, Remote monitoring, Sustainability, Digital Workforce, etc.) of our customers. We work with a strong partner ecosystem and its state-of-the- art solutions to deliver such programs. We also take ownership of delivery & post- implementation support, monitoring & reporting services to ensure the continued success of your digitalization initiatives.

Capabilities

Our team has combination of skillsets, process domain know-how and technology expertise, which helps in addressing diverse requirements of Digital transformation in process industry. We play digital transformation execution partner (Dx-Ex partner) role to uncover value from digital investments customers have done. Following are few of our Dx-Ex capabilities:

Gap assessment, Benchmarking, Dx Roadmap, Identification of Use cases, Benefit Analysis/ROI, PMC, etc.).

Digital Transformation Consulting – Process Manufacturing

Tridiagonal Solutions is a trusted partner for successful manufacturing excellence, digital transformation strategy and implementation of digital / Industry 4.0 tech stacks in process manufacturing. Our process domain understanding, technology expertise and hands-on implementation experience enables us to take deeper view to devise sustainable Dx strategy and roadmap.

Core Expertise: Digital transformation for Production / Process Optimization, Energy Optimization, Quality Prediction,Predictive maintenance and Safety & Sustainability.

Dx Tech Stacks: IT-OT assessment, Advanced process control / AI-based Process control, Predictive Analytics, Energy Management (Scope 1 & 2), Digital workforce

- Understanding the scope (requirement): Current V/S Expected performance (IT-OT)

- Whether or not the current infrastructure is I-4.0 ready

- How the current data architecture looks like; Sensors, DCS/SCADA, etc.

- Additional sensor Implementation for I 4.0 use cases

- Whether the entity of Data Infra is OPC compliant/evaluating the communication protocols supported

- Identification of IT-OT Data requirement Tech Stack

- Designing ISA 95 compliant IT-OT architecture

Domains: MES, Historians, Industry Data Ops, IT-OT integration, Cloud infrastructure, Unified namespace architecture (UNS), ISA 95, Asset hierarchy

Benchmarking few key performance metrics and Zone to Win- To define Vision, Mission, Goals, Digital Culture, Talent & Skills, Technology Leadership, etc.

- Identifying the pain areas in Process manufacturing

- Blueprinting Dx - Defining the Process Problem Statements – production/ process optimization, Maintenance, Quality, Safety, Sustainability

- Creation of business Case for operational benefits

Operations Areas: Manufacturing planning & schedule, Quality, Overall yield, Zero defects, Energy optimization, OEE, etc.

Financial Analysis - Projected Savings, Benefits report, ROI assessment

- Creating the financial savings report-projected savings per asset/process

- Business case(s) for various tech stack implementations for each identified areas (Process optimization, Maintenance, Quality, Safety, Sustainability)

- Assessment of the required budget

- Estimated savings in the CAPEX, OPEX

- Dx investment planning for 5 years with IRR / NPV / Payback period calculations

For e.g. ROI, Pay-back period, Investment planning, Capex-Opex budget allocation

Develop Priority Matrix depending on the Digital Maturity Assessment, Availability of Assets, Process, People

- Prioritizing the Business problems based on the savings, requirements and challenges

- Identification of Dx Tech Stack(s) for implementation

- Implementation plan and risk mitigation strategy

- Change management

- Industry 4.0 training needs identification

- Cultural transformation roadmap

For e.g. Prioritisation matrix, Dx roadmap, Cultural transformation, Training

.png?width=186&height=189&name=Project%20Management%20Consulting%20(PMC).png)

PMC for Implementation of Solution(s) – Continuous efforts for e.g., IT-OT integration, Sensor Placements, APC, APM, OTS, Digital Workforce, Others

- Develop Scalability Framework

- Implementation roll-out plan across different locations

- Continuous Improvement - Gap Analysis and Scope of Improvement – KPIs, New / Advanced Use Cases

- Evaluation of Usage of the solution implements

- Post implementation benefit analysis/ ROI calculations

- Identification of gaps in solutions that are implemented and rectification plan

- Identification of Training needs

- New Use Cases definition, New modeling framework, Advanced Analytics, etc.

PMC: Ensuring successful Dx implementation and post-implementation ROI’s

Implementation of Historians, MES, Industry Data Ops, Data engineering, Data Lake set-up on cloud, Cloud infrastructure management etc.

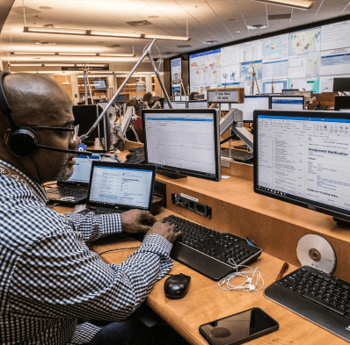

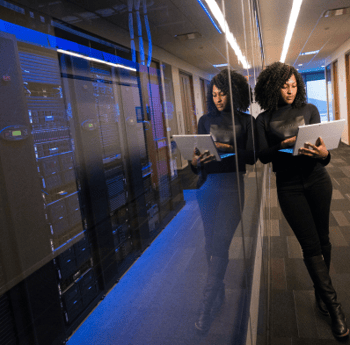

IT-OT Integration – Industrial Data Fabric for Smart Manufacturing

Cyber-physical systems integration is a key foundational element for successful digital transformation. Leveraging IIOT, communication protocols, advanced edge systems and cloud integration; Tridiagonal solutions specializes in architecting the best suited IT-OT convergence strategies for Industry 4.0 end applications.

Core Expertise: ISA 95 data architecture, Data engineering, Edge deployments, Industrial Data Ops, Cloud integration, process data contextualization, Knowledge graphs, Data fusion, Data Ontology, IIOT implementation, Data fabric consulting, Visualization, Unified named space (UNS), etc.

Dx Tech Stacks: MES, MOM, IIOT, Historians, Data fusion, Data Fabric, Cloud integration

The ISA-95 framework provides standards for integrating enterprise and control systems

- Implement data integrations that link MES, enterprise resource planning (ERP) systems, IIoT platforms, data lakes, and analytics solutions

- Hierarchal model helps to structure and align information from different levels of the corporation -- multiple cells, lines, areas, sites and even enterprises

- Information model - defines the inter-relationships

- Defines the flow of data from different functional models

Domains: ISA 95, Asset hierarchy, MES/ MOM, Industry Data Ops, Unified namespace architecture (UNS)

The data contextualization provides contextualized and standardized data points to the operations team

- Creation ‘Relationships’ using graph database (Knowledge graph)

- Embedding industrial/ domain knowledge to the raw data so that it can become information

- Optimized data, structures, storage and transformation.

- Predefined data models, context models, and combination functions

- Contextual data identifies bottlenecks and opportunities for improvement.

Key Areas: Data enrichment, process / domain contextualization, Knowledge graph

Partner Solutions: Cognite

Provide the tools, process and organizational structures to support the data-focused enterprise

- Creating the financial savings report-projected savings per asset/process

- Business case(s) for various tech stack implementations for each identified areas (Process optimization, Maintenance, Quality, Safety, Sustainability)

- Assessment of the required budget

- Estimated savings in the CAPEX, OPEX

- Dx investment planning for 5 years with IRR / NPV / Payback period calculations

For e.g. ROI, Pay-back period, Investment planning, Capex-Opex budget allocation

.png?width=185&height=180&name=Unified%20Name%20Space%20(UNS).png)

Develop Priority Matrix depending on the Digital Maturity Assessment, Availability of Assets, Process, People

- Prioritizing the Business problems based on the savings, requirements and challenges

- Identification of Dx Tech Stack(s) for implementation

- 5-year self-sustainable Dx implementation roadmap (phase-wise) creation

- Implementation plan and risk mitigation strategy

- Change management

- Industry 4.0 training needs identification

- Cultural transformation roadmap

For e.g. Prioritisation matrix, Dx roadmap, Cultural transformation, Training

PMC for Implementation of Solution(s) – Continuous efforts for e.g., IT-OT integration, Sensor Placements, APC, APM, OTS, Digital Workforce, Others

- Develop Scalability Framework

- Implementation roll-out plan across different locations

- Continuous Improvement - Gap Analysis and Scope of Improvement – KPIs, New / Advanced Use Cases

- Evaluation of Usage of the solution implements

- Post implementation benefit analysis/ ROI calculations

- Identification of gaps in solutions that are implemented and rectification plan

- Identification of Training needs

- New Use Cases definition, New modeling framework, Advanced Analytics, etc.

PMC: Ensuring successful Dx implementation and post-implementation ROI’s

Tridiagonal Solutions Chemical 4.0 practice leverages Industry 4.0 tech stacks to implement Manufacturing Excellence and Digital Transformation solutions.

Process Data Analytics (Timeseries)

Tridiagonal Solutions Chemical 4.0 practice leverages Industry 4.0 tech stacks to implement Manufacturing Excellence and Digital Transformation solutions. We bring a combination of tools, techniques, expertise, and solutions to support various initiatives (such as APM, APC, Digital Twin, Remote monitoring, Sustainability, etc.) of our customers. We work with a strong partner ecosystem and its state-of-the-art solutions to deliver such programs. Furthermore, we also take ownership of delivery & post-implementation support, monitoring & reporting services to ensure the continued success of your digitalization initiatives.

Core Expertise: Time series analytics, predictive maintenance, soft-sensors, energy optimization, emission management, APM

Dx Tech Stacks: AWS, Azure, Cognite, Seeq, Kelvin, python, pyspark, R and other

- Advanced analytics on timeseries dataset

- Root cause analysis using unsupervised ML techniques

- Open loop recommendations for process improvements

- Tracking KPI deviations and first principle modeling

Techstacks:

- Python-based frameworks

- Supervised and unsupervised modeling

- Flask, Django based web Apps

- Seeq, Cognite, AWS, Azure

- Offers real time prediction for offline lab measurements for quality control

- Translation of low frequency data to high frequency

- Inferentials building using process, mechanical and quality data

- Tracking KPI deviations and first principle modeling

Techstacks:

- Supervised ML techniques

- Boosting and bagging methodologies

- Physics informed ML models for high fidelity predictions

- 1st principles driven ML model for reliable predictions

- Real time optimization of process through neural networks and plant constraints

Techstacks:

- Hugging face APIs

- GPT-3, GPT-3.5, BERT

- Language representation models

- Zero shot model

.png?width=190&height=189&name=Use%20Case%20(Repeated).png)

- % O2 prediction in flue gas for fired heaters

- Real time Yield prediction in batch processes

- Real time %LOD prediction in batch dryers

- Feed strategy optimization in aluminum smelters

- Channelling prediction in blast furnace operations

- BTP temperature prediction in sinter plant operations

- Real time IBP prediction in crude distillation unit

Tridiagonal Solutions bespoke solutions tailored to support the industry requirements leveraging the advanced capabilities such as digital twin, custom applications and connected analytics.

Advanced Data Analytics

Tridiagonal Solutions bespoke solutions tailored to support the industry requirements leveraging the advanced capabilities such as digital twin, custom applications and connected analytics. Enhancing the analytics and visualization for the plant engineers and operators with improved decision making. These solutions are backed by our industry experts which helps the organizations to enable agile development at scale and better adoption through these utilities. Enhancing the current data science practise with 3D models with enhanced contextualization to enabling causalities through connected analytics using sequential modeling approach empowers the shop floor team to gain better insights from their data.

Core Expertise: Time series analytics, predictive analytics, digital twin, metadata modeling, connected analytics, smart Apps for Energy and process optimization

Dx Tech Stacks:AWS IOT Twinmaker, Azure Digital Twin, Cognite, VidyaTec, Seeq, Smart Applications

- Advanced 3D models-based visualization for the telemetry data modeling

- Integrated data management – Timeseries, SAP, MES, ERP, AIMS, and others engineering information

- Analyze the complete history of the processes and equipment

- Knowledge graphs for better information management through metadata modeling

Techstacks:

- Knowledge graphs

- Master data management

- Cognite, AWS, Azure, VidyaTec

- Mimic the plant conditions by connecting all the upstream and downstream equipment

- Improve the decision making through equipment level correlations and causalities

- Enhance the process and equipment reliabilities through sequential models

Techstacks:

- Supervised ML techniques

- Boosting and bagging methodologies

- Seeq, Cognite, AWS, Azure

- Open source based tailored frameworks focused to provide the custom insights for point problems

- Applications focused to accelerate the scalability and adoption

- Built to deliver high value through physics based modeling for real time constraint modeling and optimization

Techstacks:

- Python, scipy, Tensorflow, pytorch

- Supervised and unsupervised based learning

- Fisrt principles based mechanistic modeling

- Solutions leveraging neural networks for image processing and video analytics solving complex industrial problems

- Leveraging artificial neural networks for fault detection through complex learning patterns

- Digitization of offline scanned manufacturing records through OCR

- Analyzing complex microstructures and visual quality inspection

Techstacks:

- Deep learning frameworks – Tensorflow, Pytorch - CNNs, RNNs, GAN

- Generative model, transformers - GPT-4 and others

- Improving the decision making through connected analytics for CDU operations

- Digital twin for complex refinery and petrochemical units

- Plant wide optimization

- Smart Apps for process/energy/utilities optimization for manufacturing companies

- Compressors

- Exchangers

- Steam optimization

- Energy management

- Steam and condensate balance

- Image analytics for safety measures

- Complex material microstructure pattern prediction

- Prediction of external cracks for metal casts

Optimization

Tridiagonal Solutions Chemical 4.0 practice leverages Industry 4.0 tech stacks to implement Manufacturing Excellence and Digital Transformation solutions.

Process Optimization

With the increasing and dynamic market demands it is important to identify the opportunities for continuous improvement of the operations through real time optimization of the equipment and processes. With our deep domain expertise and process optimization know-how leverage the frameworks for improving the overall optimization strategies by making the appropriate control move to enhance the maintenance, planning and scheduling practices.

Core Expertise: Process optimization, Advanced process control (APC), Enhanced life of assets, Real time optimization (RTO), Energy optimization

Dx Tech Stacks: Imubit, Honeywell APC, Aveva, Siemens GPROMS

.png?width=168&height=168&name=Advanced%20process%20control%20(APC).png)

- Advanced process control for complex and dynamics chemical operations for autonomous operations

- Integrated PID controllers for multivariate control strategy to dynamically respond to the process changes

- Minimize process off-spec, enhanced quality control and reduced process variabilities

Techstacks:

- Honeywell Forge, Aveva APC, Aspen DMC

.png?width=176&height=176&name=Deep%20learning%20process%20control%20(minute%20by%20minute%20optimization).png)

- Offers real time process control through complex analysis of MVs, CVs and DVs

- Integrated non-linear inferentials for real time quality control and constrained objectives / targets

- Accounting the impact of uncontrollable disturbances

- Identifies the opportunity to optimize the processes every minute within the non-linear constrained environment

Techstacks:

- Reinforcement learning

- Non-linear inferentials for quality prediction

- Physics informed RTOs for enhancing the overall performance of the site to meet the cost / objective functions

- Objective oriented model intended to optimize the economic profits

- Continuous production optimization to improve the asset reliability, throughput and energy efficiency

Techstacks:

- Honeywell RTO, Aveva RTO

- Optimize the performance of various processes such as distillation columns, reactors, and compressors

- Reduce energy cost for facilities including utility management

- Optimization of the air-to-fuel ratio in furnaces to improve combustion efficiency, reduce fuel consumption, and minimize emissions

- APC for compressor optimization

- RTO for gas plant optimization

- Stabilization of Distillation columns through APC

Building predictive emissions monitoring systems for carbon footprint reduction, Opex-based and Capex-based carbon abatement.

Energy Optimization and Management

With our data driven expertise leverage the frameworks for energy optimization for critical operations across the value chain. These frameworks are focused on reducing the overall energy consumption through predictive analytics by optimization of the process parameters. These frameworks can enable the organization to track their carbon footprint and energy consumption rate through effective utilization of the data across the organization.

Core Expertise: Energy optimization, carbon footprint reduction, utility optimization, fuel management

Dx Tech Stacks:> PEMS, Real time optimization, Energy tracking and utilization

Track the carbon footprint under the category of scope 1 and scope 2 emissions.

- Direct emissions from owned or controlled sources

- Indirect emissions from the generation of purchased electricity, steam, heating, and cooling consumed

Domains: Industry Data Ops, Energy management, Carbon abatement

.png?width=194&height=168&name=Predictive%20Emissions%20Monitoring%20System%20(PEMS).png)

Estimate and predict the emissions of pollutants from critical processes across the manufacturing facilities. Improve the decision making through predictive analytics by optimizing combustion processes and reducing the fuel consumption. Track the emissions – NOx, SO2, CO, CO2, PM and others.

Operations Areas: Boiler fuel consumption, condenser and reboiler duty management, HVAC energy management.

Leverage data analytics for GHG analysis and reporting by effectively collecting the emissions, electricity, steam and natural resource consumption across the manufacturing facilities. Benchmark and prioritize the energy consumption for critical equipment for various carbon abatement programs, enabling compliance and sustainability optimization.

For e.g. ROI, Pay-back period, Investment planning, Capex-Opex budget allocation.

- Fuel optimization in boiler operations

- Steam and chilled water consumption in reboilers and condensers

- HVAC energy management

- Heat integration studies and pinch analysis

- Motors and critical drives energy management

Steady-state simulations for process debottlenecking/ optimization. Dynamic simulation (OTS) for effective start-ups and shutdown.

Process Modeling and Simulation

Tridiagonal Solutions Chemical 4.0 practice leverages several technology stacks for developing the process simulators intended to enables better decision making for critical operations including startup/shutdown procedures, maintenance workflow strategies and planning and scheduling optimization. With dynamic simulators improve the real time process performance by understanding the dynamics through efficient and integrated visibility. Integrate the physics based dynamic plant models mimicking the DCS controllers for effective control of critical conditions.

Core Expertise: Time series analytics, predictive maintenance, soft-sensors, energy optimization, emission management, APM

Dx Tech Stacks: AWS, Azure, Cognite, Seeq, Kelvin, python, pyspark, R and other

- P&ID mapping and process flow simulators

- Process troubleshooting and debottlenecking

- Process stabilization

- Design modification and process improvement studies

- Heat integration and pinch analysis

- Thermodynamics and process reconciliation

Techstacks:

Aspen Hysys, Honeywell Unisim, Siemens gproms

.png?width=152&height=164&name=Dynamic%20Simulation%20(Operator%20training%20simulation).png)

- Real time plant simulators

- Process benchmarking

- Process operators training – plant control operations

- Process improvement and benchmarking studies

Techstacks:

Honeywell OTS, Yokogawa OTS, Emerson OTS, Aveva OTS

- Physics informed simulators based on deep learning networks

- Enhancing overall performance of the site to meet the cost / objective functions

- Objective oriented model intended to optimize the economic profits

- Continuous production optimization to improve the asset reliability, throughput and energy efficiency

Techstacks:

Imubit, Smart Optimizers.png?width=146&height=156&name=Virtual%20Reality%20(VR).png)

- 3D training and simulations using VR

- Enriched remote operations experience

- Immersive assistance in remote maintenance workflows

- Enhanced plant safety

- Enhanced productivity through efficiency and smart operations

Generative AI (LLMs) has the potential to transform the way industry has been operating over the decades. With more than a quarter of data residing in unstructured format.

Generative AI

Generative AI (LLMs) has the potential to transform the way industry has been operating over the decades. With more than a quarter of data residing in unstructured format, it becomes difficult to extract the meaningful insights from these documents. These documents hold crucial information regarding the raw materials, production, quality and carious other compliance reports which are necessary to be documented on daily basis. Domain infused-LLMs help to convert this unstructured information to a more meaningful and accessible format, which can be used for various process troubleshooting and improvement studies.

Core Expertise: Zero shot models, few shot LLMs, Multimodal, language representation model, domain specific models, task specific and advanced analysis.

Dx Tech Stacks: OpenAI, Azure OpenAI, AWS Bedrock, Hugging face, Google Gemini, Cognite, Bloom and others

- Advanced analytics on timeseries dataset

- Fault classification and categorization

- Analyze the complete history of the processes and equipment

- Provides domain-specific responses and guidance to user prompt

- Helping users navigate complex problems with expert insight

Techstacks:

- Task specific – BART, ALBERT

- Multimodel model

- Advanced Analysis – GPT-4

- Zero shot model

- Few shot LLMs – GPT-3, T5 (Google)

- Offers implicit or explicit active task execution to assist users in achieving their outcomes.

- Streamlining workflows and improving efficiency

- Chatbots for siloed data interpretation and augmentation

- Historical alarm report analysis

- Content generation and language standardization

Techstacks:

- Domain specific models – BioBERT, SciBERT

- GPT-3, GPT-3.5, BERT, Grover

- Language representation model – XLM, Multilingual BERT

- Extraction of meaningful information from siloed and unstructured data

- Vendor management using

- Automation of codes and standards references for asset integrity and fire and safety standards

- Content creation using social media sentiments for improved decision making

Techstacks:

- Hugging face APIs

- GPT-3, GPT-3.5, BERT

- Language representation models

- Zero shot model

.png?width=190&height=189&name=Use%20Cases%20(Repeated).png)

- Interpretation of Certificate of Analysis (COA) reports

- Conversational AI for Daily Drilling Reports (DDR)

- Information extraction from Daily Production reports (DPRs)

- Interpretation and analysis of Incident reports for RCA for critical equipment

- Advanced statistical analysis of time series data

- Conversational AI for Batch production using SAP, QMS and Historians

- Sustainability – Energy, Steam/water, waste analysis

Upskilling and training (level 1, level 2, level 3) for Digital tech stacks such as AI-ML, Time-series analytics, Python, Cloud AI-ML (Azure, AWS), etc.

Bridge the gap

Implementing time-series manufacturing data analytics relies on various factors, including a combination of skills. Modern data science techniques, rooted in mathematics and statistics, require not only tool-centric expertise (like Python and data cleansing) but also a deep understanding of the domain, machine learning algorithms, and optimization techniques. Our 'Pilot Guided Services Framework' has managed multiple projects, identifying key challenges such as data quality and the application of statistical and ML methods for optimal results. To bridge the skills and tool gaps, we offer a Knowledge Sharing and Learning program titled ‘Bridge the Gap in Manufacturing Data Analytics’. For further details, visit our article

Core Expertise: Time series analytics, predictive maintenance, soft-sensors, energy optimization, emission management, APM

Dx Tech Stacks: AWS, Azure, Cognite, Seeq, Kelvin, python, pyspark, R and other.

- Basic understanding of Time-series / Manufacturing Process Data

- Data Preparation & Pre-processing – Data Cleansing, Conditioning, descriptive statistics

- Process Understanding and how to represent the system from data analytics perspective

- Introduction to Level of Analytics – Descriptive, Predictive, Prescriptive, etc.

- Exploratory Data Analytics - Feature identification, reduction, Covariance methods, basic formula techniques

- Basic introduction to ML libraries & statistical templates and its applications

- Use-cases examples – How Time-series data analytics is used

User Profile: Process engineers, Technologists, Plant operations team, Maintenance & Reliability Enggs., IT teams, etc

Duration: Typically, 1 week. Depends on the Audience Size.

- Introduction to building formulas and statistical/ ML python scripts for advanced analytics (for e.g, Root Cause Analysis, Critical Parameter Identification, Soft Sensors, etc.)

- Advanced Data modeling techniques (using Python, Jupyter Notebook, etc.) on your data and results

- Model construction, application / validation, Visualization and implementation – Right Methods (Use case-specific)

- Introduction to commercial analytics tools

- User Profile / Audience: Users (process domain experts) who have basic coding background (Python) and understanding on various Statistical/ ML algorithms to create Models and apply it for analytics

- Prerequisite: Python expert in ML and its application

- Duration: Typically, 1 week. Depends on the Audience Size.

- Python-based template creation and widget building

- Soft-sensor building (using Physics-based, First-principle Models)

- Advanced reports and Dashboarding

- ML Model(s) deployment methods

- Best Practices / Guide & Methods for Data Analytics

- User Profile / Audience: SMEs / Process domain experts with Mathematical Modeling, Process Modeling, Python/ML expertise

- Duration: Typically, 1 week. Depends on the Audience Size.

- Tridiagonal will provide analytics engineering support to identify and execute the use cases on your data with your users. We will work on the identified three (3-4) Use cases.

- The prerequisites in terms of the data requirements (signals/tags/volume, etc.), process details, data modeling & analytics objectives will be finalized. The use case can be worked on the Off-line / On-line data, provided the customer give an access to the data /analytics environment. We will submit the analytics outputs and ROI reports to the teams

- Duration: Typically,4-6 weeks. Depends on the number of Use Cases

Accelerate your digital transformation projects with Smart Apps and Time-to-value (TTV) program

- Smart Apps

- TTV A-33 Program

Connect ready-to-deploy smart apps to your existing IT-OT / Industry 4.0 infrastructure such as historians/ data lakes, edge software’s, Industry data ops platforms, COTS analytics tools, etc. We have codified the AI-ML smart frameworks with best practices of deploying end applications (smart apps) for process manufacturing such as production optimization, predictive quality, predictive maintenance (of critical assets), energy optimization, safety, etc. Leveraging these frameworks allows the industry to implement the ML models at scale.

Smart Apps: Compressors, Pumps, Bioreactors, Furnace, Smelters, Heat exchangers, Golden Batch, Distillation columns, Evaporators, Virtual metering, etc.

The TTV-A33 Accelerator program is Digital transformation (Dx) execution framework to ensure faster scale-up and quicker business value realization for your digital transformation programs/projects. TTV- A33 program is an outcome of our global experience, which is designed to ensure successful deployments and quicker roll-out at scale of advanced analytics use cases.

Our large customers have derived much quicker business value by adopting the TTV Accelerator program – A recipe for 33 X - SCALE-UP AND VALUE CREATION.

Industries

Industry domain know - how with technology (digital) expertise.

Oil & Gas

We provide end-to-end digital solutions for Oil and Gas and alternate energy. Our team consists of process engineers who have industry/operations experience of process optimization, maintenance and sustainability.

Areas: Advanced process analytics (predictive/ prescriptive), Advanced process control (APC), Real-time optimization (RTO), AI-based process control, Energy optimization, Digital twin, Operator training simulation (OTS), Generative AI, etc.

Life Sciences/Pharma

We have been working with fortune 100, 500 life science and pharma companies from last 16+ years. Our core expertise includes process development and scale-up & tech transfer, manufacturing intelligence, energy optimization, etc.

Areas: Golden batch analytics, Bioreactor hybrid modeling, Batch-to-batch analysis, Predictive maintenance, product quality prediction, OEE, NLP, Gen-AI for COA.

Metals, Mining & Cement

Our metals, mining and cement practice deals with process optimization, energy efficiency and predictive maintenance of critical units/ processes. We support customers right from setting up industry data ops/ data fabric to predictive analytics, digital twin, AI-based process control.

Areas: Smelter digital twin, Furnace optimization, Kiln optimization, Sintering plant, ID fan, Mills, OEE, etc.

Food, Beverages & CPG

We cater to safe and sustainable operation of F&B customers using Industry 4.0 tech stacks. The major focus is on quality, production increase, waste reduction, energy efficiency, inventory reduction, operating cost reduction.

Areas: OEE, product deviation monitoring, batch cycle time, product quality prediction, Equipment run length optimization, Gen AI, etc.

Chemicals & Petrochemicals

Our focus in chemical industry is majorly on conversion units such as distillation columns, reactors, steam optimization, etc. The end objective is to enhance operational efficiency, agility, and sustainability.

Areas: Predictive quality (soft sensors), Advanced process control for columns, Predictive maintenance of critical assets (heat exchangers / condensers, compressors, etc.)

Power & Renewables

We have experience in deploying solutions for power generation, transportation and distribution. The focus is in improving asset reliability and prevent unplanned shutdowns. forecasting environmental conditions that impact energy production, etc.

Areas: Coal blend quality prediction, Turbines and boiler energy optimization, Predictive maintenance of ID fans, Emissions modeling, Cooling tower make-up water optimization.

Mitigating Technical Debt to Maximize Value in Manufacturing Dx

According to one of the surveys, more than 70% of digital transformation initiatives fail and the success ratio is less than 5 %. There are too many enablers (technology solutions- big, small) for Dx.

Decoding AI for Batch Process Optimization

Batch processing is one of the most common manufacturing approaches amongst many industries such as Biopharmaceuticals, Pharmaceuticals, and Specialty Chemicals.

Crafting Success Transforming Distillery Operations with IoT and AI

Join us for an exclusive webinar with AWS, where we unveil the secrets to revolutionizing the Distillery industry through the seamless integration of AWS IoT and AI solutions with Tridiagonal SMEs. Discover how this powerful combination enables the organization to improve fermentation/distillation efficiency by optimizing steam, fuel and chemical consumption.

Resources

Explore the breadth and depth of our digital transformation solutions in process manufacturing.

Why Tridiagonal?

Team having exposure and expertise of developing scalable solutions across multiple platforms.

Schedule a Call today!

Uncover how our capabilities can propel your organization forward. Provide your focus areas, and we will deliver tailored solutions designed to meet your unique objectives.